It is estimated that during Operation PRAKARAM (in the wake of terrorist attack on Indian Parliament), over one million mines were laid along 3200 km long Indo-Pak border, covering nearly 35000 acres of land. The sheer magnitude of the undertaking can be gauged from the fact that it took almost two years of sustained effort by thousands of soldiers to clear the area and return the land to the owners.

Humanitarian Demining

It is always carried out in a post-conflict context. Its primary objective is to carry out total clearance of mines of the affected area. As no records are available, the first and perhaps the most crucial step, is to identify and mark mine contaminated areas to warn the civil population and to prioritise their clearance as per the availability of resources. Humanitarian demining seeks a near total clearance of the land from all types of mines – at least 99.6% as per the United Nations. The amount of time it takes to clear an area is less important than the safety of the clearance personnel and the reliability and accuracy of demining process.

Also read: Recollection of 1971 War

The current rate of humanitarian mine clearing is about 100 thousand per year. According to some estimates it may take up to 100 years before the world is rid of all laid mines. Thus, cost and damage to the environment become major considerations of the methodology adopted. Due to the enormity of the problem, considerable impetus is being given to the development of more refined machines in the recent years.

Current Mechanical Mine Clearance Systems

It is a well accepted fact that mechanical means have to be used for primary mine clearance in all contexts. But as all machines have their limitations; other means have to be used to supplement the same to enhance degree of assurance to the required level.

Also read: The price of ignoring military mind

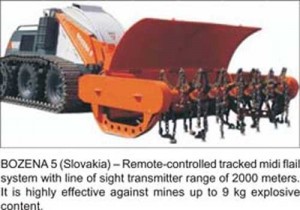

Mechanical mine clearance systems are divided into two basic categories – remote- controlled and manned systems. A remote-controlled system is controlled from a safe distance using a hand-held radio-frequency module whereas a manned system is controlled from a protected position within the demining vehicle. Remote-controlled systems are generally of smaller size and suffer from inability to withstand blasts of high explosive content. Bozena 5 of WAY Industries of Slovakia is considered to be one of the best machines in this category.

As regards the manned systems, there are three basic techniques of mechanical mine clearance – flails, trawls and ploughs.

Flails

Systems using hammers at the end of chains attached to a rotating drum or shaft are referred to as flails. The rotating axle causes the hammers to beat the ground rapidly, with the intent of detonating mines. A hammer strike may cause detonation, disruption or ejection of mines. Flails are generally mounted on the front or rear of heavily protected vehicles. They are broadly categorised as mini flails (up to 5 tons), midi flails (5-20 tons) and heavy flails (above 20 tons). Mini flails perform well only as a quality assurance/proofing tool.

Systems using hammers at the end of chains attached to a rotating drum or shaft are referred to as flails. The rotating axle causes the hammers to beat the ground rapidly, with the intent of detonating mines. A hammer strike may cause detonation, disruption or ejection of mines. Flails are generally mounted on the front or rear of heavily protected vehicles. They are broadly categorised as mini flails (up to 5 tons), midi flails (5-20 tons) and heavy flails (above 20 tons). Mini flails perform well only as a quality assurance/proofing tool.