According to an assessment of the United Nations, there are more than 100 million mines lying buried in various present and past conflict zones in over 60 countries in the world. The International Committee of the Red Cross estimates that the casualty rate from mines currently exceeds 26,000 people every year. The current stockpile in the world is estimated to be in excess of 100 million mines and this is increasing every year with the current annual world production of over five million mines. What is more significant is the fact that up to three million fresh mines are still being laid every year.

Though the world is trying to rid itself of all mines, the present rate of clearance is less than one tenth the rate of fresh laying. It is apparent that despite the ongoing movement to ban landmines the world over, mines will continue to play a major role in all conflicts in the foreseeable future. As a matter of fact, rapid technological advances are being made in their designs and methods of laying. Their actuating mechanism varies from pressure to seismic disturbance. They incorporate anti-handling devices and booby traps to make their disarming and recovery hazardous.

Every army has to be equipped and trained to undertake mine clearance operations both during and after a conflict. Mine clearance in its broadest meaning implies clearing a designated area of all land mines.

Every army has to be equipped and trained to undertake mine clearance operations both during and after a conflict. Mine clearance in its broadest meaning implies clearing a designated area of all land mines. Mine clearance can be done by two primary methods – either by locating and physically removing them or by actuating/destroying them at site. Given suitable ground conditions (soil, slope and foliage), the ideal methodology found so far has been initial destruction by mechanical means followed by manual proofing.

Nature of Mine Clearance Tasks

Methodology of mine clearance depends on its objectives. Mine clearance in a conflict environment demands different solutions than those applicable during peace.

Mine Breaching in War

Mines are laid prior to or during operations to create an obstacle to impede the advance of adversary. The primary purpose is to defend an area, to channelise enemy forces into pre-designated areas by imposing restrictions on their movement and to deny the use of large operationally critical areas. Mine clearance during conflict is commonly referred to as minefield breaching as the aim is to clear a passage through a minefield and not to demine the entire area. Time is of critical importance.

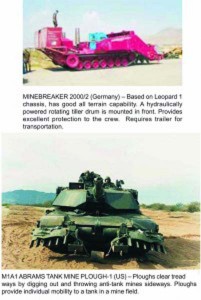

Leading armoured vehicles carry mine-clearing ploughs for their own mobility through a minefield. Ploughs clear tread-ways by digging out and pushing mines sideways. Proper passages have to be subsequently breached for follow up vehicles and supply echelons. These safe lanes are created with mechanical means and subsequently probed manually. All militaries, therefore, need a large number of mine clearing machines. Along with speed of breaching, such machines are required to provide adequate safety to the operators from bursting mines and hostile enemy fire. They should also possess matching mobility to be able to keep pace with advancing columns.

It is estimated that during Operation PRAKARAM, over one million mines were laid along 3200 km long Indo-Pak border, covering nearly 35000 acres of land.

Post-Operations Mine Recovery

Extensive minefields laid prior to and during a conflict have to be recovered subsequently to put the land back to agriculture and other applications. Each and every mine has to be accounted to avoid civilian casualties. It is an extremely time consuming and risky task. Though all mines laid are duly recorded, their recovery poses immense problems due to a variety of reasons like drifting due to rains, dragging by rodents, growth of vegetation and even accidental detonation by animals. Therefore, the only practical option is to use mechanical means to destroy mines in areas where manual recovery becomes untenable. A high degree of assurance and safety of recovery parties, rather than the speed of recovery are of paramount importance.

It is estimated that during Operation PRAKARAM (in the wake of terrorist attack on Indian Parliament), over one million mines were laid along 3200 km long Indo-Pak border, covering nearly 35000 acres of land. The sheer magnitude of the undertaking can be gauged from the fact that it took almost two years of sustained effort by thousands of soldiers to clear the area and return the land to the owners.

Humanitarian Demining

It is always carried out in a post-conflict context. Its primary objective is to carry out total clearance of mines of the affected area. As no records are available, the first and perhaps the most crucial step, is to identify and mark mine contaminated areas to warn the civil population and to prioritise their clearance as per the availability of resources. Humanitarian demining seeks a near total clearance of the land from all types of mines – at least 99.6% as per the United Nations. The amount of time it takes to clear an area is less important than the safety of the clearance personnel and the reliability and accuracy of demining process.

Also read: Recollection of 1971 War

The current rate of humanitarian mine clearing is about 100 thousand per year. According to some estimates it may take up to 100 years before the world is rid of all laid mines. Thus, cost and damage to the environment become major considerations of the methodology adopted. Due to the enormity of the problem, considerable impetus is being given to the development of more refined machines in the recent years.

Current Mechanical Mine Clearance Systems

It is a well accepted fact that mechanical means have to be used for primary mine clearance in all contexts. But as all machines have their limitations; other means have to be used to supplement the same to enhance degree of assurance to the required level.

Also read: The price of ignoring military mind

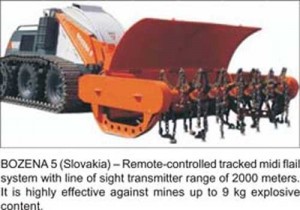

Mechanical mine clearance systems are divided into two basic categories – remote- controlled and manned systems. A remote-controlled system is controlled from a safe distance using a hand-held radio-frequency module whereas a manned system is controlled from a protected position within the demining vehicle. Remote-controlled systems are generally of smaller size and suffer from inability to withstand blasts of high explosive content. Bozena 5 of WAY Industries of Slovakia is considered to be one of the best machines in this category.

As regards the manned systems, there are three basic techniques of mechanical mine clearance – flails, trawls and ploughs.

Flails

Systems using hammers at the end of chains attached to a rotating drum or shaft are referred to as flails. The rotating axle causes the hammers to beat the ground rapidly, with the intent of detonating mines. A hammer strike may cause detonation, disruption or ejection of mines. Flails are generally mounted on the front or rear of heavily protected vehicles. They are broadly categorised as mini flails (up to 5 tons), midi flails (5-20 tons) and heavy flails (above 20 tons). Mini flails perform well only as a quality assurance/proofing tool.

Systems using hammers at the end of chains attached to a rotating drum or shaft are referred to as flails. The rotating axle causes the hammers to beat the ground rapidly, with the intent of detonating mines. A hammer strike may cause detonation, disruption or ejection of mines. Flails are generally mounted on the front or rear of heavily protected vehicles. They are broadly categorised as mini flails (up to 5 tons), midi flails (5-20 tons) and heavy flails (above 20 tons). Mini flails perform well only as a quality assurance/proofing tool.Flails are the most widely used and the oldest mechanical system. Although they were first used during World War I, their development has been slow. It is only during the last decade that major efforts have been put in to refine them further.

Flails have some major limitations. They are bulky, costly and guzzle fuel. There are many cases of mines being left broken or unexploded or even being thrown far away from their original placement. Their effectiveness in rocky soil is suspected. In dry conditions, the chains create dense clouds of dust. Still, most people consider the flail to be an indispensable part of all major demining programmes, especially in foliated areas. Hydrema 910 MCV and Aardvark JFSU flails are the most popular machines with demining community. Scanjack 3500 is a heavy duty double-flail machine which has also performed well in humanitarian demining tasks.

Flails have some major limitations. They are bulky, costly and guzzle fuel. There are many cases of mines being left broken or unexploded or even being thrown far away from their original placement. Their effectiveness in rocky soil is suspected. In dry conditions, the chains create dense clouds of dust. Still, most people consider the flail to be an indispensable part of all major demining programmes, especially in foliated areas. Hydrema 910 MCV and Aardvark JFSU flails are the most popular machines with demining community. Scanjack 3500 is a heavy duty double-flail machine which has also performed well in humanitarian demining tasks.

Trawls/Rollers/Tillers

Systems employing one or more hydraulically operated rotating horizontal drums with special metal spikes or teeth are referred to as trawls or rollers or tillers. They are designed to exert pressure to detonate or break up mines. They are heavy, difficult to transport and their operative costs are prohibitive. They have the capacity to till soil up to a depth of 50 centimeters and are fairly effective except on undulating, rocky and heavily vegetated areas.

Rollers can either be mounted on a prime mover or else be pushed/towed by another vehicle. They are particularly useful for breaching passages through minefields or for proofing unmetalled roads. Germany’s Mine Breaker 2002/2 with tiller drum is being widely used.

Ploughs

They are used for individual mobility of a vehicle (generally armoured) through a minefield. An attachment with ploughing teeth is fitted in front of the vehicle at a slant. The teeth dig out mines while the slant throws them sideways, thereby clearing the tread way of the vehicle. Ploughs are commonly used by assaulting armoured columns.

Combination Machines

A number of combination machines incorporating various aspects of diverse techniques are also under development to increase assurance level. KMT 7 combines rollers and plough techniques to clear full tank width with enhanced assurance over the cleared passage.

Recent Developments in Demining Machines

Initially demining machines were developed purely for military purposes. They are designed to clear only a navigable path through a mine field. For such machines, the prime considerations are speed of clearance, safety of operators, self-mobility to keep pace with advancing columns and ruggedness to withstand hostile operational environment.

A great deal of research is yet to be carried out to fully understand soil behaviour under stress of flails, tillers and rollers as that causes shifting of mines and affects their subsequent destruction.

Subsequently they were modified and used for humanitarian demining, though their effectiveness in area clearance remains suspect. Military depends primarily on ‘mechanical demining’, whereas for humanitarian purposes it is always ‘mechanically assisted demining’. The mechanical methodology by itself cannot provide the required clearance assurance as yet. Additionally, the present crop of military machines is not environment friendly.

Humanitarian demining has been providing the necessary momentum for advances in demining technology over the last decade. Efforts are being made to develop machines with better mine clearance assurance with speed and safety. Cost of demining also continues to be major consideration.

It is generally accepted that flails offer best hope although they disturb top soil and create clouds of dust. Flails are also very good at removing vegetation, saplings, and even small diameter trees. Therefore, flails are attracting maximum R&D funding. Major efforts are being made to improve their performance by understanding the effects of configuration of hammers and their geometry. Rollers, on the other hand, can be most effective in the early stages of humanitarian operations to allow the establishment of supply routes.

However, a great deal of research is yet to be carried out to fully understand soil behaviour under stress of flails, tillers and rollers as that causes shifting of mines and affects their subsequent destruction. Even the relationship of speed and direction of rotation to demining effectiveness is yet to be conclusively established. Reduction of skipped zones and minimising of throw-outs are twin challenges which all demining machine designers are facing. Efforts are also being made to counter limitations imposed by foliage and vegetation.

Need for Multi-Purpose Demining Systems (MPDS)

In addition to mine breaching during war, militaries have to be prepared to undertake demining during peacetimes. One option is to have separate custom-made systems for each activity for optimum performance. But that would involve huge costs and multiple inventory as separate sets of machines would be needed for demining in different contexts.

A more cost-effective and prudent option could be to have multi-purpose machines which are versatile enough to perform demining functions in all contingencies. The following major benefits will accrue:-

A more cost-effective and prudent option could be to have multi-purpose machines which are versatile enough to perform demining functions in all contingencies. The following major benefits will accrue:-

- Huge Savings in Costs. Demining systems are complex and come with a very high price tag. MPDS could be held as reserves for war while utilising them for humanitarian demining. These could be either be used by own troops under the aegis of UN demining programmes or could even be leased out to demining NGOs. Inventory management will also be easy.

- Enhanced Operational Readiness. Operational readiness depends on having equipment in functional order at all times. If MPDS are employed for humanitarian demining, they need not be mothballed during peacetimes. Additionally, sustained usage of equipment in live mine conditions will generate inputs for updating repair and spares support. Performance parameters will also get validated.

- Optimum Utilisation of Equipment During its Life Cycle. Military demining equipment is used only during hostilities. Equipment bought by India in the wake of 1971 war became obsolete without having been put to any operational use. It got wasted out practising mine breaching in dummy minefields during training exercises.

- Realistic On-the-Job Training. Due to inherent risks involved, it is well nigh impossible to provide adequate realistic training to demining parties during peacetimes. Actual mine fields cannot be duplicated in training exercises. Operators never get sufficient opportunity to get familiar with their machines to develop confidence in their reliability and performance. Their training is limited to driving their machines in training areas. Employment on humanitarian demining will provide on-the-job realistic training to demining parties.

Recommended Parameters of Proposed MPDS

It should be a stand alone system. It should not be an attachment to an armoured vehicle or any other fighting vehicle, lest its use during peacetimes depletes fighting resources and reduces war potential.

Adequate safety should be provided to the operators from bursting mines, both anti-personnel and anti-tank, and observed enemy small arms fire. The system should also be capable of withstanding blasts of up to 12 Kg explosive content without suffering major damage. Quick replacement of damaged parts in field should pose no problems. Driver’s cabin should be comfortable enough for sustained effort over prolonged periods.

As of now no single mechanical mine clearance technology can clear mines under diverse terrain and environmental conditions, although development of versatile mine clearance machines, incorporating multiple mechanisms, is becoming a distinct reality. It is time India opts for multiple-use mine clearance systems for better efficiency and economy.

It should provide required mine clearance assurance with facility to vary degree of assurance by controlling speed and depth of strikes. Military operations require speed, whereas during post-operations mine clearance and humanitarian demining safety is of utmost importance. However, further proofing by supplementary means will invariably be required for area clearance.

The machine should be able to work under varying terrain and operating conditions such as, dry/wet soil, undulating ground, extreme temperatures and excessive humidity. It should also be capable of tackling foliage and thick vegetation with minimal damage to top soil and environment.

Excellent cross-country mobility is an essential requirement to enable MPDS to keep pace with armoured columns. Additionally, it should lend itself to easy transportability for long distance movement for humanitarian demining. Operation and maintenance in field conditions should be easy. As flails kick up too much dust all filters and other sensitive instruments need to be dust-proof.

Conclusion

By its very nature, total mine clearance of any area can never be guaranteed. Many feel that mine clearance is at best a risk-reduction process. Terrain permitting, machines provide the best, the fastest and the most cost-effective option. They can be supplemented by other methods but not substituted. Therefore, machines will continue to be the primary choice. But machines have their own limitations.

The present equipment is mainly adapted from military mine breaching machines and not enough research has been carried out so far to analyse their performance related dynamics with regard to terrain. However, since the emergence of humanitarian demining as a major commitment, renewed efforts are being put in to incorporate requirements of enhanced assurance, safety and cost-effectiveness. Flails and rollers appear to have the necessary potential as viable stand-alone systems for primary clearance. But, behaviour of different soil conditions under pressure exerted by flail strikes or ground penetrating tools of tillers needs to be better understood for optimum performance.

As of now no single mechanical mine clearance technology can clear mines under diverse terrain and environmental conditions, although development of versatile mine clearance machines, incorporating multiple mechanisms, is becoming a distinct reality. It is time India opts for multiple-use mine clearance systems for better efficiency and economy.