The Indian Air Force (IAF) inducted the HS 748 Avro in the 1960s. This twin-engine turboprop aircraft was initially designed by British aircraft Original Equipment Manufacturer (OEM) Avro which was later absorbed by Hawker Siddeley. It first flew in 1960 as the Avro 748 and was renamed HS 748 when Avro company merged with Hawker Siddeley but the Avro name continues till today. It was actually intended for the civilian market, but India was one of its customers who modified it and employed it for military purposes too. It was license produced as HS 748M by Hindustan Aeronautics Limited (HAL). A total of 89 Avros were produced of which 72 were inducted into the IAF and the remaining 12 into Indian Airlines. Hawker Siddeley stopped HS 748 production in 1988, but the IAF continues to use them till date and, according to the World’s Air Forces 2023 published by Flight International, today, the IAF has 57 Avro HS 748 aircraft on its strength.

As mentioned earlier, the aircraft was designed essentially for civil aviation and so the original door had to be modified for loading large size military cargo as well as for para dropping personnel and payload without hitting the tail section. Moreover, performance from hot and high airfields was not ideal for Indian conditions and remained less than satisfying. The fact that they were first inducted in the 1960s is an indicator of their age-related problems such as reliability, maintenance and cost of sustenance. Moreover, their air conditioning system is not ideally suited for India and does not cater for extreme hot temperatures that prevail over Northern India during the summer months.

The C295 project is a huge accomplishment for the Indian private industry as it is the first project of its kind in which a complete military aircraft will be manufactured in India by a private company…

The original vision at the time of induction was that its replacement would be an indigenously designed one. However, HAL’s efforts to design an improved version of the HS 748 and a joint venture with USSR’s aerospace major Antonov to design a derivative of the AN-132 failed and were given up. The need for replacement of the Avro was foreseen by the IAF in 2009, and a case prepared in 2010 for a replacement aircraft. The Defence Acquisition Council (DAC) cleared the proposal in July 2012 and a Request for Proposal (RFP) for 56 aircraft was issued in May 2013. Airbus C 295 and Italian Alenai Aeromacchi’s C-27J met the Transfer of Technology conditions but based on the price comparison, the bid by Airbus and Tata Group was approved by the DAC in May 2015. It took another six years before a formal contract was signed for 56 Airbus C295s on September 23, 2021. Fortunately, the price offer remained unchanged. As the IAF readies to receive its first C295, this article looks at the deal and the benefits it holds for the Indian aerospace industry.

The Aircraft

First, let us take a look at what the deal brings to the IAF’s tarmac. The C295 is a medium tactical transport aircraft that was originally designed in the 1990s as Nurtanio CN-235 by the Spanish company Construcciones Aeronáuticas SA (CASA) which became a subsidiary of the European Aeronautic Defence and Space Company (EADS) in 1999, under the name EADS CASA and in 2009, was absorbed into Airbus Military. It made its first flight on November 28, 1997, and entered service with the Spanish Air Force in 2001. In the current nomenclature, “C” represents CASA the manufacturer and then a three digit number, of which the first indicates the number of engines, two in this case, and the next two its target payload of 9.5 tonne. However, this figure varies from version to version.

The C295 is a versatile, new generation tactical airlift aircraft specialised in air transport missions, under all types of weather conditions both during day and night. Its other versions to which India could switch to in future, include Armed/Ground Intelligence Survey And Reconnaissance (ISR), Signals Intelligence (SIGINT), Airborne Early Warning (AEW), Maritime Surveillance, Maritime Patrol Aircraft (MPA)/Anti Submarine Warfare (ASW), Air-to-Air Refuelling (AAR), Medical Evacuation, Water Bomber capable of dispensing 7,000 litre of water or fire retardant and VIP role. Most of these versions can be reconfigured easily to transport version and back due to palletised modular systems.

According to the Airbus website, the transport version has a maximum cruising altitude of 25,000ft with an equivalent cabin altitude of 8,000ft, a service ceiling of 30,000ft on both engines and 13,500ft on a single engine, Maximum Take Off and Maximum Landing Weight of 23,200kg, a range of 1790km, cruising speed of 260knots, take-off run of 2,200ft and a landing run of 1,050ft. It has an endurance of up to 11 hours. Its performance characteristics allow it to use short, semi-prepared runways as its heavy duty landing gear can sustain additional weight so that the take-off and landing maximums are similar. Thus, it can carry out a safe landing immediately after an aborted take-off with Maximum All Up Weight (MAUW). Its twin-wheeled nose landing gear also provides advantage on unpaved and rough landing surfaces.

India is moving forward with the mantra of ‘Make in India, Make for the World’ and that now it is heading to be a huge manufacturer of transport aircraft…

The aircraft has a rear ramp door for quick-reaction and para dropping of troops and cargo. The ramp allows for easy loading of mission pallets, cargo, passengers and litters for medical evacuation. It also has a side door that is used for para drop. There are provisions to install four bubble spotter windows on the fuselage to aid visual search. Reportedly, the Indian version is called C-295MW, the ‘M’ signifying military version and ‘W’ indicating it has winglets incorporated in its airframe for enhanced performance. The aircraft has modern technology and avionics and is perhaps the best current type in its class, with attendant benefits.

The Big Deal

The deal for 56 aircraft is for $2.5 billion and among the 34 C295 users, this will make India the largest user worldwide. It provides for the first 16 to be produced at the CASA facility in Seville, Spain and delivered to India in fly away condition within 48 months of the deal being signed (delivery planned between September 2023 and August 2025) and the remaining 40 to be manufactured between 2026 and 2031 at a new facility set up in Vadodara where the first C295 squadron of the IAF is expected to be raised. The first C295 produced in India is expected to roll out in September 2026. After these 40 have been delivered, hopefully the assembly line will be commissioned to produce more aircraft for Indian and foreign customers.

The Indian manufacturing consortium is led by Tata Advanced Systems Limited (TASL) which is the Tata group’s strategic entity under Tata Aerospace and Defence (Tata A&D) in an industrial partnership with Airbus Defence and Space SA Spain. According to a press release by the MoD, the project is expected to generate 600 highly skilled jobs directly, over 3,000 indirect jobs and an additional 3,000 medium-skill employment opportunities with more than 42.5 lakh man-hours of work within the aerospace and defence sector. All 56 aircraft will be equipped with an Electronic Warfare Suite that will be indigenously manufactured by Bharat Electronics Limited (BEL) and Bharat Dynamics Limited (BDL). The project will give a boost to aerospace ecosystem in India.

Private Industry’s Debut Aircraft

The Indian aerospace industry had been fettered to the public sector for long with HAL, an internally inefficient organisation with a low productivity work culture, being patronised by the government in favour of the more efficient private sector. Huge amounts of money and real estate have been bestowed upon HAL and it has 21 luxurious complexes all over the country where a large number of employees work union hours. Successive audit reports by the Comptroller and Auditor General (CAG) have highlighted the mediocre productivity of most of our public sector undertakings including HAL. The IAF and the aviation arms of the Indian Army and the Indian Navy that are the customers for HAL have never experienced the delight that the US military derived from Boeing or Lockheed Martin. There is also the public sector culture of brawny labour unions which inhibit efficient work. Government patronage has meant that the inefficient public sector has dominated the Indian aerospace industry while the much more productive private sector has largely been kept out of that ambit. The work culture of HAL is unlikely to evolve and achieve the efficiency levels that private enterprises display. Privatisation of HAL could be one solution, but it is unlikely that the strong lobby of HAL will permit that to happen easily. The government, possibly aware of this dilemma, has been changing its disposition towards private enterprise, especially in defence and aerospace, in recent years.

The BSF, which is the only Central Armed Police Force to have an air wing catering to all other CAPFs, has also shown interest in the C295 and is waiting in the wings for its turn to make a bid…

The C295 project is a huge accomplishment for the Indian private industry as it is the first project of its kind in which a complete military aircraft will be manufactured in India by a private company. It will involve development of specialised infrastructure in the form of hangars, buildings, aprons and taxiways. During the process of manufacturing in India, it is expected that all the suppliers of TATA Consortium who get involved in special processes will gain globally recognised accreditation of National Aerospace and Defence Contractors Accreditation Programme (NADCAP) which provides independent certification of manufacturing processes for the aerospace industry.

The Tata group has joint ventures with US OEM Lockheed Martin Corporation for producing F-16 wings as also complete empennages and fuselage components for C-130J Super Hercules; it produces two empennages every month. It also has arrangements with Swiss aerospace and defence holding company RUAG Aviation for Dornier Do-228 fuselage and wing assembly manufacture, Sikorsky Aircraft Corporation which is a Lockheed Martin company, for S-92 helicopter cabins, and Pilatus Aircraft Ltd for PC-12 trainer. Tata has also been in a joint venture with Boeing called Tata Boeing Aerospace (TBAL) in Hyderabad for the co-production of AH-64 Apache helicopter fuselages and other aero structures since 2016, and delivered its first AH-64 fuselage in 2018. Tata A&D is also making aero structures for Boeing’s CH-47 Chinook helicopters. In the future, TASL is expected to add more and more projects for components and assemblies for international OEMs. Tata A&D is also likely to manufacture LEAP engines for international engine OEM CFM International. Thus, TASL’s competence and leadership in the aerospace domain as a private player is unquestionable. However, the C295 project adds a new dimension altogether to TASL’s repertoire. Moreover, it catapults India into the elite group of nations namely the US, UK, Russia, France, Italy, Spain, Ukraine, Brazil, China and Japan that can manufacture military transport aircraft.

Other Indian companies too have had notable successes in the aerospace arena and have been manufacturing components and sub-assemblies albeit for foreign OEMs and at a smaller scale for HAL. Dynamatic Technologies has been making vertical fin assemblies for Sukhoi 30MKI fighters as also aero structures for the A320 family of aircraft and the wide body A-330 aircraft of Airbus. Hyderabad’s VEM technologies manufactures centre fuselage for the Light Combat Aircraft Tejas. Mahindra’s aerospace division has been manufacturing aero-structures, metallic parts and assemblies for some time and supplying them to other aircraft manufacturers. It is the only private sector Indian aircraft manufacturer as it owns GippsAero of Australia which manufactures the Airvan 8 and the Airvan 10. Unfortunately, bureaucratic wrangling at the office of the Director General Civil Aviation (DGCA) has prevented these aircraft to be certified in India.

The C295 is a versatile, new generation tactical airlift aircraft specialised in air transport missions, under all types of weather conditions both during day and night…

This is not a comprehensive list of aerospace manufacturing companies in India; the point being belaboured is that, with Tata leading the way, more success stories can be expected to mature over future years. That is a big advantage for the Indian aerospace industry.

Make in India and Atmanirbhar Bharat Abhiyan

‘Make in India’ and ‘Atmanirbhar Bharat Abhiyan’ are two slogans that are guaranteed to find a place in print and electronic media on a daily basis. While inaugurating the Vadodara C295 facility on October 30, 2022, Prime Minister Narendra Modi said: “In the coming years, the Defence and Aerospace sectors will be two important pillars for making India Atmanirbhar.” He also said that India is moving forward with the mantra of ‘Make in India, Make for the World’ and that now it is heading to be a huge manufacturer of transport aircraft. He also said he could foresee that India would soon be manufacturing large passenger aircraft that will proudly bear the words ‘Made in India’. While that may not come to pass in the near future, the C295 programme will serve to provide a major boost to ‘Atmanirbhar’ of the government inasmuch as it represents the grand entry of Indian private sector into manufacturing complete military aircraft.

A substantial proportion of C295 components, sub-assemblies and major component assemblies of aero structure are planned to be manufactured in India. Of the 40 C295 aircraft being manufactured in India, eight will be assembled from semi-knocked down kits and another eight from completely knocked down kits. The remaining 24 are planned to have progressively more and more indigenously produced assemblies and sub-assemblies. According to the MoD, manufacturing of more than 13,400 components, 4,600 sub-assemblies and all major component assemblies will eventually be carried out in the country, while some equipment such as engines, landing gear and avionics will be provided by Airbus Defence and Space and integrated on the aircraft by the Tata consortium. The indigenous content of the C295 produced in India is projected by the MoD to be around 96 percent of the work that is done in Spain on the Airbus C295. However, this figure is manipulative statistics as critical components including the aero-engine remain out of the deal’s ambit.

There is also a 30 per cent offset woven into the deal which should bring lucrative business to Indian entities, especially in the aerospace manufacturing arena. The Tata consortium has identified more than 125 domestic Micro, Small & Medium Enterprises (MSME) suppliers spread across the country. Thus, the project will generate thousands of skilled and semi-skilled jobs; around 240 engineers are being trained at the Airbus facility in Spain. Another boost to Atmanirbhar is the establishment of a D-level Maintenance, Repair and Operations (MRO) (in some groups, the ‘O’ is expanded to Overhaul) facility in India. This facility will act as a regional MRO hub for all variants of the C295. In addition, the OEM will also discharge its 30 per cent offset obligation through direct purchase of eligible products and services from Indian offset partners giving further boost to the economy and contributing to Atmanirbhar.

While the production of C295s from Vadodara will give us self-sufficiency, self-reliance will remain elusive and can only result from developing our own capability to produce complete aircraft indigenously…

Military Benefits

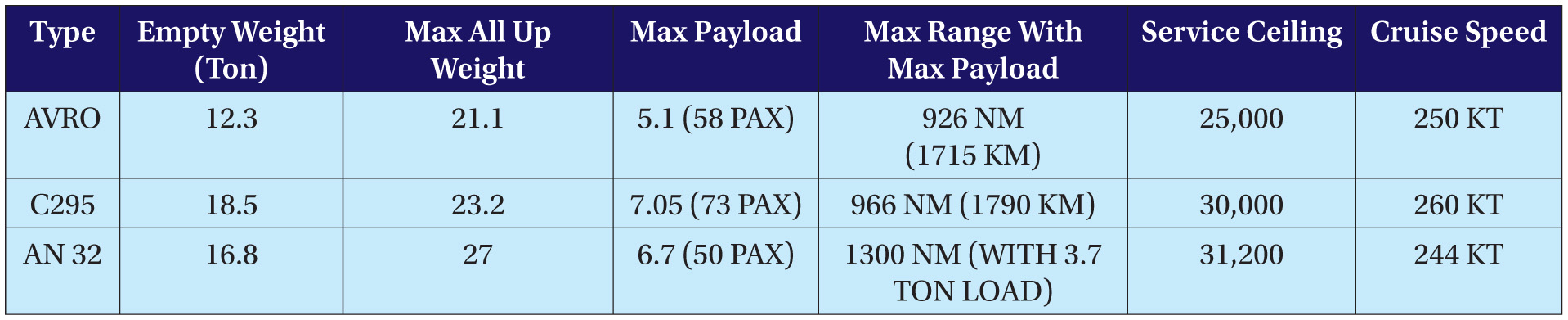

The C295 brings huge relief to the IAF as a replacement for the Avro HS 748 which has outlived its useful life and is now being flogged by the IAF as a matter of necessity. It also represents an edge over the Avro not only in terms of performance and capability but also by way of modern technology as it is four decades more advanced than the Avro which flew first in 1960 while C295’s maiden flight was in 1997. A comparative chart is placed below (Figure 1).

The data on AN-32 has been added in Figure 1 to highlight the fact that the AN-32 fleet of the IAF are also in need of replacement in the coming years. The IAF was technically a launch customer for the AN-32 in 1986, and de-induction is planned to commence around 2030, just around when the 40th indigenous C295 is being rolled out at Vadodara. As by then, the C295 would already be flying in the IAF, it would make sense to replace the AN-32s also with an existing type with attendant advantages of economy of scale, ease of logistics, lower cost of training, ground equipment and maintenance.

Additionally, there are reports of nine C295s being ordered by the Indian Navy and six by the Indian Coast Guard at an additional cost of Rs 18,000 crore. The C295 cannot match the 2,160nm range of existing P8Is of the Indian Navy, but can supplement them and the Dornier Do-228s usefully if a version configured for maritime recce and surveillance operations is manufactured at Vadodara. Reports indicate that the Centre for Air Borne Systems (CABS), an establishment under Defence Research and Development Organisation (DRDO) is already working on Active Electronically Scanned Array (AESA) Radar optimised for air and sea target detection and tracking. The maritime version will have multi-mode radars, electro-optic cameras and sono buoys, which will empower them for air dominance operations over the high seas. The BSF, which is the only Central Armed Police Force (CAPF) to have an air wing catering to all other CAPFs, has also shown interest in the C295 and is waiting in the wings for its turn to make a bid. Thus, there is considerable military benefit that the Indian aerospace and defence industry stands to derive from the deal.

Civil Benefits

Unlike in case of fighter aircraft, transport aircraft are essentially adaptable to military and civil use. Indeed, the Avro HS 748 and the C295 were both originally designed as platforms for civil use. Once the assembly line is established, it would be a comparatively easy task to tweak it to produce different versions of the C295 for civil and military use.

This is delightful news as our endeavours to produce transport aircraft indigenously have been largely unsuccessful. This is despite HAL’s experience of license producing the Avro HS 748 and the Dornier Do-228. HAL procured a license in 1983 and produced 125 of these in Kanpur. A joint venture between HAL and Antonov to design a new aircraft has also fizzled out. HAL is working on Hindustan-228, a derivative of the Dornier Do-228 for civil use which is yet to fly.

The National Aerospace Laboratories (NAL), a constituent of the Council of Scientific and Industrial Research (CSIR) is the only government aerospace R&D laboratory in the civilian sector. Despite being around since 1959, possessing 200 acres of real estate in central Bengaluru and having received enormous investment, it has not designed an aircraft worthy of production. Saras, a light transport aircraft designed by NAL to carry 19 passengers, flew first in 2004, but the first prototype crashed in a test flight and the programme was put on the back burner until 2016 when it was revived with a 14 passenger target. The IAF has agreed to procure 15 of this platform with an option on 45 more later. A 19-seat version is also on the anvil. NAL is also designing a 90-seater which may have a jet engine or a turbo-prop one that is yet to be decided. Thus, the Indian aerospace industry definitely needs to build up its credibility in the transport manufacturing space.

With Indian civil aviation spreading its wings and the projected number of airliners planned to go from the current 700-plus to around 2,200 over the next decade, there is interest from Boeing and Airbus to set up manufacturing facilities in India. An aero-engine OEM may also set up shop in India with those numbers. The C295 deal promises to open up these vistas, encouraging international entities to move manufacturing to India.

Concluding Remarks

While the C295 deal has brought gratification and hope about the future of the Indian aerospace industry, one cannot gloss over the fact that leading edge technologies in the domain of aero engine, undercarriage and radars still remain elusive and are not part of this deal in terms of Transfer of Technology. Swaminathan Aiyer, the noted economist and columnist, distinguishes between the two nuances of Atmanirbhar – self-sufficiency and self-reliance. While the production of C295s from Vadodara will give us self-sufficiency, self-reliance will remain elusive and can only result from developing our own capability to produce complete aircraft indigenously without importing any component, sub-component or technology. So what inhibits us from growing that capability? It is the R&D that needs to be stepped up. The government spends a fair amount although not adequate as per experts on R&D but, significantly, that money is spent through public sector enterprises most of which have a track record of inefficiency. It is time that, just as a large amount is being spent on an aircraft deal with a private player, substantial and meaningful R&D funds be diverted to private players. Alternatively, existing R&D facilities should be opened up to the private sector. That is the only way to meaningful Atmanirbharta in the Indian aerospace and defence industry.

Well researched article. What India really needs to watch is the percentage of localization of indigenous components. Our contracts from the recent past especially with US defense contractors will give an idea about how serious are the Western companies about localization percentage going up.

Go capt great insights indeed but certainly lopsided on ur comments on HAL I don’t know which area of IAF u wer involved but would like to remind u that support to ageing fleets which are operated by IAF is a stellar contribution which u deny to admit

We r happy that private industry is really growing but what about long term after sales upport and spares the OEMs are going to fleece us for sure this is wher HAL has been at the forefront so ur comments on medicrcy and poor productivity are primarily due to lack of decisive direction at the customers and govts end

Pl visit HAL to understand what the organisation stands for and what it has delivered till now