Dockyards have often grown from older historical bases by “Alteration and Additions” during spikes of modernisation and expansion dictated by evolving rivalries between maritime nations. As the needs of a deep ocean fleet were not anticipated earlier, such expansions were necessarily constrained by the inherent embryonic limitations of the original site. Any nation aspiring to global naval status needs to carefully reformulate its strategy in developing the kind of dockyard necessary to serve its blue water fleet. To do that, one needs to know what is meant and included in such a modern facility. This submission does not propose or detail any specific alterations to existing dockyards. That task is best left to the reader and analyst who using the parameters set out herein will be able to make a quantitative assessment of how to address specific shortcomings if any.

A well planned design of a dockyard must necessarily depend on a futuristic vision of the navy…

The strength of a navy is usually expressed as the number of warships in each of the different categories that make up its fleet. Little mention is made of their operational effectiveness; a measure which best represents the ability to deploy those assets at a given state of readiness in a sustained manner. In reality, the true strength is dependent on both parameters. Shareholders, who are owners of merchant fleets, have long recognized this. It directly affects their income. Management of large fleets now insist on Reliability Modeling during development so that they can prioritize their budget and determine targets before operations begin. Once in commission, they incessantly monitor fleet availability and search for ways to reduce the operational down time. It is surprising that maritime nations and governments seem less concerned about the status of their very expensive naval fleet. Even without the use of dedicated repair facilities, the mission readiness of civilian fleets is consistently much higher than that of most navies. This gap continues to widen.

Since Independence, there have been large increases in public expenditures for higher education. As a result, the country now has a substantial pool of naval architects and engineers. It is, therefore, difficult to reconcile that naval ships and submarines continue to be repaired or modernised overseas in countries that have smaller numbers of such professionals. The reason for this anomaly is that the available tooling and productivity in warship repair are well below necessary levels. One of the more important factors that govern the operational efficiency of any Navy is the quality and capacity of its dockyards that are entrusted with the care of its ships.

Dockyards have often grown from older historical bases by “Alteration and Additions” during spikes of modernisation and expansion dictated by evolving rivalries between maritime nations. As the needs of a deep ocean fleet were not anticipated earlier, such expansions were necessarily constrained by the inherent embryonic limitations of the original site. Any nation aspiring to global naval status needs to carefully reformulate its strategy in developing the kind of dockyard necessary to serve its blue water fleet. To do that, one needs to know what is meant and included in such a modern facility. This submission does not propose or detail any specific alterations to existing dockyards. That task is best left to the reader and analyst who using the parameters set out herein will be able to make a quantitative assessment of how to address specific shortcomings if any.

It is difficult to reconcile that naval ships and submarines continue to be repaired or modernised overseas…

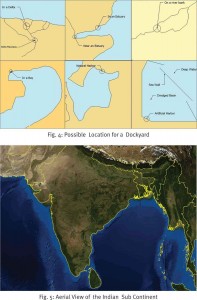

At the start, it must be emphasized that a dockyard is not a stand-alone establishment. It is an intrinsic part of a much larger size naval complex with dedicated zones for fleet administration, military and civilian housing and their medical care and other needs, fuel and lubricant storage farms, warehouses for logistics, ammunition depots and handling wharfs, military engineering services, naval satellite communications and a naval air base. The quality and description of these entities, the supporting infrastructure and transport and their inter-relationship directly affects the performance of the navy as a whole. History shows that despite the added cost of a new industrial complex, the shifting of any industry out of an urban centre has always been extremely profitable to its owners. Therefore, area location of any naval complex from a mega city can be considered as a practical and a very attractive economical option that merits in-depth consideration.

Fleet Vision

A well planned design of a dockyard must necessarily depend on a futuristic vision of the navy. This projection is not entirely virtual. It can be deterministic when based on the combination of the historical and projected the growth of the Gross National Product (GNP) of countries that have influence in the region, the weighted size of their fleets and their shipbuilding capabilities. The US and China are the two other major countries with influence in the region. A projected likely size of their fleets for the next two decades is shown in Table 1.

|

CATEGORY CHINA – US |

||

| Aircraft Carriers (Nuclear/conventional) |

6 |

12+ |

| Attack Submarines (N: Nuclear D=Diesel) |

52-D/6-N |

52 –N |

| Ballistic Submarines Nuclear |

4 |

13+ |

| Guided Missile Nuclear Submarines |

2 |

4 |

| Destroyers/Frigates |

84 |

74 |

| Littoral Combat/Minesweepers/SUV Carriers |

53 |

80 |

Table 1: Estimated Numbers: US & China

To contain any outside threats in the Indian Ocean, it will be necessary for the Indian Navy to keep abreast with 200 ships…

It is also worthy of note that during this period, despite what may appear as a narrowing gap in fleet strength, the US will endeavour to maintain its lead. This would be possible through their innovative skills in such diverse fields of engineering as nuclear, quantum computing, fuel Cells, electronic counter measures, cyber security, super conductivity, high strength alloys, paints, gas turbines, lasers, acoustics, nano-robotics and AUV/SUVs. Should there be a formal declaration of war, the numbers tabulated could easily be doubled by both countries using their established reserves and new construction capabilities.

To contain any outside threats in the Indian Ocean, it will be necessary for the Indian Navy to keep abreast with a minimum fleet size of approximately 200 ships of similar types shown above. It must be assumed that half of these numbers will be based on each coast. Such an allocation is justifiable since no adversary with a global perspective is likely to dedicate more than half their naval assets to a specific regional conflict.

Capacity

Dockyards, also called navy yards, are essential for the specialised repair and care of the fleet. The capacity of a dockyard in terms of the integral fleet load needs to be defined and reviewed at the highest level. This is normally done for both – a peace time normal shift of eight hours and for a war time scenario using three shifts round the clock. In peace time, the dockyard should have the capacity to take on an additional five per cent work load due to unforeseen incidents and handle possible requests from allied navies. When dockyards are distinct and separated from each other due to topography, it is logical to assume that under war time conditions one of these parent bases may no longer be serviceable. Under such a scenario, the capacity of the surviving yards ought to be 100 per cent of the total fleet requirements using three shifts.

Special Requirements

A few of the special requirements specific to a modern dockyard are discussed below:

The Outside World

The perimeter of any large dockyard should be at least ten kilometres away from any major city or any centre of concentrated population. The probability of extensive fires due to wars, mishandling of inflammables, electrical shorts and giant explosions due to explosives and radiation leaks in any naval base over a 200-year period are extremely high. Their effect on the outside world cannot be ignored. The massive explosion in a small 7,000-tonne dwt. freighter ‘Fort Stikine’ in 1944 at a berth in the commercial dock in Mumbai should not be forgotten. That blast was heard over a distance of 15 kms and resulted in a loss of 800 lives, a dozen ships and extensive material damage. Since then, archives show that serious accidents of considerable magnitude have also occurred in naval yards and harbour entrances, even in times of peace.

In any country, a city centre and more so, a prime commercial district contributes far more to the Gross National Product when any land therein is used for commercial purposes instead of being used for a limited semi-industrial activity such as found at a naval complex. As proof observe that at the end of the last century, repair shops and garages in Connaught Place, New Delhi and the Shanghai Bund relocated without much fanfare. They have been replaced by high-end commercial shops and offices. The relocation of the historic Jiangnan Naval Arsenal in SE Shanghai built in 1865, the Admiralty Shipyard Leningrad built in 1705, the Danish Naval base at Holmen and others are also very relevant. As countries raise their living standards, planners are fully aware that the public will not accept the wanton exposure of large numbers of civilians to a permanent high risk of danger. It makes good sense and intelligent planning for any large naval base to be located away from major cities especially those expected to grow to mega cities in this century. The need to stay away from a dockyard can be easily perpetuated if lands adjacent to a new naval complex are designated ‘Restricted’ like a cantonment. In any case, good planning demands that some land reserve adjacent to a new dockyard be held for any required expansion of the yard at some later date.

A naval dockyard employs large numbers of civilian industrial workers who on their very limited incomes, cannot afford the high rents for accommodation within a growing city. As an example, in Mumbai, a dockyard employee’s only housing option is at their old housing colony located over 30 km away from their place of work or even further on the outskirts of the city. They are entirely dependent on public transport. As the population density in the city has increased rapidly, the suburban railway systems in urban areas are overcrowded. In Mumbai, at peak times, up to 6,000 rail commuters are packed in a twelve car rake designed to carry 2,200. Many make a daily commute over one and a half hours each way by rail/bus; most of which is done standing. They are often physically spent when they arrive for work thus reducing the overall productivity. A new naval complex that included civilian housing in closer to their work place could provide yard workers with better quality accommodation and a more relaxed and cheaper commute, free of the heavy air pollution found in a large city.

Any nation aspiring to global naval status needs to carefully reformulate its strategy in developing the kind of dockyard necessary to serve its blue water fleet…

Design Loads

The design of every building, dry dock, syncrolift, marine railway and piers in a dockyard must when loaded, be able to contain the forecasted extreme seismic earthquake and wind spectrum for that region. Further, all wharfs, piers and jetties must also be capable of meeting the design wind and sea spectrum loads acting on vessels berthed at those piers. The possibility of sea level changes due to global warming must also be catered for. A design review of existing facilities using international building codes and Mooring Analysis could reveal many failures. It should be noted that such certifications are routinely required when navies and cruise liners use commercial facilities beyond their home port.

Fire Resistance and Protection

The application of fire engineering is most essential in the design of any dockyard. This is often very poorly addressed and more often, totally neglected as inferred from the lack of any historical documents. These valuation and assessment studies with proper sealed documentation for individual centres and the whole yard must include waste collection/disposal, fire detection, active fire protection both afloat and land based, passive fire protection, smoke control and management, escape facilities and emergency exits, building design, layout and space allocation, quality assurance inspections, training and drills, fire dynamics and modeling, human behaviour and communication failure predictions during fires, risk analysis of remaining assets during a fire including air space, basin and dry dock management during a fire, and prevention of any failures due to lightning flashes and strikes.

Operations involving loading or unloading of ammunition between ships and shore should not be permitted within a dockyard. Separate facilities away from the yard are essential. Fig. 1 (give above) shows such a facility recently commissioned by the UK in compliance with this requirement.

Control

The air space over a dockyard must be permanently closed to civil aviation and restricted to permitted service aircraft only. Similarly, the maximum zone safe TNT load, missile and torpedo fuel and engine fuels and lubricants allowed at one time at every pier, jetty or workshop centre and on main traffic zones, must be established and enforced. A Yard Safety Board that shows the principal hazards and quantities in real time together with their locations in berthed ships, piers and centres is essential. Similarly, safety issues connected with the handling and towing of nuclear ships/submarines, radio-active and medical waste within the dockyard, evacuation routes for residents and the first-aid facilities in the adjacent naval complex and civilian sites need to be assessed, catered for, documented, tested out by exercises and controlled in real time.

The design of every building, dry dock, syncrolift, marine railway and piers in a dockyard must be able to contain the forecasted extreme seismic earthquake…

Services

Electricity, water, waste water, compressed air and communication services are required by every centre, berthing pier, dry dock and repair berth. The expense of a reinforced service tunnel for housing and distribution of these services is minimal compared to the lifetime costs and delays when using alternative above surface methods. Similarly, a central reinforced underground remotely operated main suction connecting all the docks to a central pump house is also desirable. The electrical and fresh water requirements of a dockyard deserve special mention. Alternative sources and local reservoir capacities ought to be carefully assessed to ensure these are adequate. Through the widespread use of solar and wind farms and solar distillation, the new complex could be a net exporter of power and fresh water to an adjacent city. Demands for services at finger piers and dry docks are best serviced by piping led through a service tunnel through a Services Office located at the head of the pier or dry dock. The containment and disposal of leaked reactor coolant, oil spills, medical waste from ships at berths and contingency measures in the event of outages or strikes, are also part of the services that must be planned for and refined by simulated periodical tests duly documented.

Security

Asymmetric warfare by terrorists is a new threat and a reality which needs to be addressed. The outer land perimeter of the dockyard must be secured by a continuous heavy-duty concrete wall with a double barbed wire top and an inner security pre-fab siding spaced 15 metres away from the outer wall. This safety zone should be monitored by automated day and night optic and audio surveillance equipment. The space between fences ought to be concreted over for high speed motor access to deal with any threat. At the sea end, the entrance to the yard must be confined to a passage between two gateway buoys with surface radioactive sensors and trainable cameras. The drill for entering the naval basin from other ports must also include an underwater inspection. This bottom search for explosive devices is best done by diver-assisted Unmanned Submerged Vehicles fitted with underwater cameras and lighting.

The navigation of all marine traffic in the basin ought to be controlled from a Harbor Master Control tower similar to that seen in an airport or at the Port of Rotterdam. Vehicle and pedestrian traffic to the yard must be monitored by face recognition software, PIN scans and electronically filed in real time. All commercial vehicles entering the yard must be automatically scanned for explosives and radioactive materials from the underside and top sides. To ensure drive-through suicidal raids are not possible, twin-set automatic steel armour entry barriers spaced thirty metres apart are mandatory.

The yard must also maintain a designated high speed security boat available on a 24/7 basis. All incoming electronic, radio-active and photographic equipment should be documented and controlled. The meta-data gathered must be preserved for at least a year and reviewed continuously for any abnormalities.

Berthing

Berthing at piers for 60 per cent of the entire naval fleet and 100 per cent of its yard craft, should be catered for. An adequate vehicle parking space for the crew should be provided adjacent to the main piers above their main cross connecting road. Because of the huge difference in design loads, the walled sea-front should be divided into sections dedicated for aircraft carriers, submarines, destroyers and cruisers, littoral craft and naval auxiliaries and yard craft separately. Finger piers from the sea-front are far more advantageous than linear or necklace piers. They offer better protection from the sea and reduce the overall siltation especially when they are located transverse to the flow.

Each pier and open dry dock must be serviced by two or more 50-tonne electric cranes capable of radially tracking to both sides. The length of the finger pier should exceed 30 per cent of the largest aircraft carrier. Bollards and fairleads should be load tested every five years and tagged accordingly. In general, ships must be moved to sheltered waters when forecasted sea conditions approach 80 per cent of the maximum design conditions.

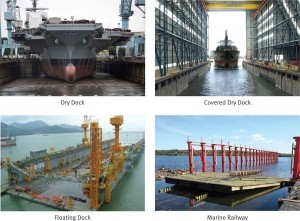

Keeping Dry

The underwater repair and maintenance of a ship requires it to be out of the water in a dry environment. To achieve this, ships, submarines and dockyard auxiliary craft can be docked using any of the following methods described below and shown in attached Figs 2 and 3 (above).

Graving Dock

These could be fully relieved, partially relieved or solid. The relief refers to the hydrostatic load from sea water seeping in and acting on the buried surfaces. The water-tight integrity at the entrance of a graving dock is maintained either by one or more hinged buoyancy gates, horizontal sliding caisson or a wedge-shaped vertical sliding caisson. Solid Graving Docks either gravity or tension pile assisted are most desirable.

Floating Dry Docks/Barge Lifts

The former consists of a bottom sectioned pontoon with fixed vertical wings. The latter consists of a sectional barge whose buoyancy can be controlled. As they operate in water continuously, they are prone to corrosion in sea water which causes a short life span relative to a graving dock and ever increasing maintenance demands.

Marine Railways

A platform which can travel on rails into the basin and return to land with the vessel docked on it.

Vertical Syncrolift and Transfer System

A floating dock makes use of the buoyant force of the pontoon. In a Syncrolift, the ship is transferred to a platform lowered to the appropriate depth. The platform with the vessel on it is then hoisted up on to land by electric winches installed on either side of the platform. The winches are designed such that they can heave up the platform at a constant rate according to the weight distribution of the ship. Once at land level, the vessel is shifted transversely or longitudinally on trolleys at the traversing station. Therein forced parking must be zoned for fire safety and designed to accommodate the required crane facilities. A submarine hangar for specialised submarine repairs is best located in line with the lift. Ships up to 30,000-tonne DWT are now routinely lifted on a Syncrolift.

Dockyards were initially set up to be centres of unmatched technical excellence and speed specializing in complex engineering of strategic importance…

Barge Crane for Lifts and Tests Afloat

These can be dumb, tug-assisted or self-propelled. For a large yard, the latter is preferable. In order to service the fleet described earlier, one should expect to see all or most of the following major facilities in a modern dockyard on each coast. These estimates are determined on the basis of current intervals for routine hull maintenance and ‘half-life’ refits. It is assumed that external bottom grooming and surveys will be done by modern robotic crawlers to reduce the time spent in dock.

- Two 350-metre length dry docks for carrier repairs.

- Four 250-metre length preferably covered dry docks for destroyers/frigates/auxiliaries.

- An 8,000-tonne Syncrolift for submarines; a re-enforced traversing bay and a holding park for not less than six submarines/small craft both active and reserve. A submarine hangar at the head of the Syncrolift is essential for refit work.

- A 500-tonne marine railway for smaller naval and yard craft. Tugs, barges and yard transports often have minor accidents frequently. These usually involve ropes and flotsam around their shafts/propellers. They need to be quickly hoisted, repaired and returned to work. Since a marine railway extended into the basin has the minimum of tidal constraints, it allows for a quick repair and is, therefore, the preferred option.

- A 1,000-tonne self-propelled heavy lift barge crane for yard and naval salvage lifts prior to docking.

- A segregated 150-metre length covered Dry Dock dedicated to nuclear submarines. A precision Gantry Crane for nuclear refuelling and rail head to accommodate the heavy coffins for the spent hot fuel rods removed during a planned overhaul or post accident repair and a link to the designated graveyard should be integrated in the design.