High tensile steel welding repairs cannot be done in the open in conditions of hundred per cent humidity or in wet weather. Because of the monsoon, these conditions occur more than 14 weeks per year on either coast. Likewise, the underwater painting of ships using high performance and expensive paints requires very careful surface preparation of the ship’s bottom which should be dry. The thickness of the anti-fouling coating is especially important since the thickness at every spot must be sufficient to ablate over the guaranteed interval between dry dockings.

Whilst the demand by the General Staff for improved docking intervals never ceases, the two legitimate “dry” requirements stipulated in the existing standards are ignored during wet weather to satisfy schedules. Such actions only result in premature paint failure, external shell corrosion and embrittlement cracks in welds. Detection and repairs of such defects are very expensive and time intensive. Under wet weather conditions, the specified “dry” requirements can only be met when repairs are undertaken in a covered dry dock. The loss in productivity when working in the open in the rains, compared to that in an indoor environment, should also be considered.

A dockyard must have access to the ocean and sufficient depth of water year round…

Workshops

The size of the dockyard and the workforce required is entirely dictated by its defined workload. The workload per ship undertaken by the dockyards has been increasing yearly even though the available capacity and capability of the marine industry in the country has been steadily improving. This trend continues encouraged by the costing model used by dockyards. Unlike a market-based business, costs of capital, reserves for replacement costs and future growth, accident insurance costs, future pension liabilities, taxes, military salaries and pensions are not fully reflected in the overheads. This distortion results in lower overheads helping to feather bed low levels of productivity. In such an environment, expansion of any type of work is usually welcomed since it simultaneously increases the union membership and extends the management pyramid with little need for innovation. Because of such embedded inefficiencies, UK, Poland, Germany, Russia and China amongst others, continue to disband or trim many of their less efficient state owned enterprises or public sector undertakings in favour of the free market.

In addition to the above, dockyards generally account for their capital assets on the basis of historic accounting rather than current valuation. Because of inflation, there is a substantial gap between the two. Most of the private sector firms in the marine industry are relatively new. Their asset valuations are closer to the current values. A comparison of such common jobs in both sectors on the basis of inflation asset valuation and true costing will show that many of the simpler and identical tasks done by firms in the private sector are excellent value for money. Because of higher productivity, such firms have superior returns on capital and lower debt-to-equity ratios. They need to be encouraged. After all, except for North Korea, armies have long since abandoned growing their own food for similar reasons and rely on market resources instead.

Dockyards were initially set up to be centres of unmatched technical excellence and speed specializing in complex engineering of strategic importance. They represented the very best engineering skills in the country that could not be found elsewhere. That historic manifesto needs to be pursued far more aggressively and with greater pride. This can be achieved if dockyards continuously seek more specialised work and improvements in productivity whilst offloading the simpler jobs when there are established multiple alternative local sources available to do them. Hence, repairs by sub-contract to the Original Equipment Manufacturers (OEMs) or repair by replacement should be the preferred route for daily use items that are also commonly used by the merchant navy and the public for which facilities already exist in the country. This long list includes items such as life-saving equipment, galley and refrigeration equipment, standard ventilation trunking, light forgings and machine castings, general purpose computers and their software updates, upholstery, rigging, clothing, standard furniture, canvas gear, small boats, small engines and motors, general purpose fasteners and more.

Red tape, mendacity and cost overruns have often dogged many projects administered in the public domain…

Some detractors may claim that such sub-contract work encourages fraud. With modern technology that is no longer valid. Today, the QA documentation for sub-contracted work can include digital photographs of the defects both prior and post repairs with dimensional details using 3-D laser scans. Also, the application of business intelligence or analytics or data mining of all sub-contractual related transactions on a national scale, can now in real time detect any irregularities which could then be subject to an immediate forensic audit.

With a rational reduction in the workload, a modern dockyard should have at-most sixteen or less highly dedicated main centres that have to cater to the specialised requirements of repair of the hull, propulsion, auxiliaries, ordnance, fire control and navigation equipment of a warship. Drawing data for such repairs at any of these centres and ship-borne worksites should be available from the Central Design Office through a Virtual Private Network. CAD/CAM interfaces, smart pads, cranes and robots should be used extensively and in large numbers, especially in the Machine and Assembly Centre which is usually the largest centre in a dockyard. It would be impossible for any dockyard on a constrained footprint with many legacy buildings and infrastructure of past centuries and carrying a hundred industrial centres to be re-engineered to accommodate the facilities described herein and to comply with the international safety codes of today.

A modern independent dockyard can only operate at peak if it has a well educated and trained workforce with outstanding skills that are appropriate for today’s technology-rich digital environment. Existing entry level education standards and apprentice knowledge requirements will have to be drastically raised to reduce the existing extremely wide difference in education and training between management and workers. Simultaneously, training programs and job descriptions require serious revision. The absence of detailed operating procedures for standard jobs with their accompanying onsite training videos also needs to be addressed. It should not be forgotten that a more skilled technician has to be compensated more than adequately. The resulting increase in wages will, however, be compensated for by demands for much higher output.

Location

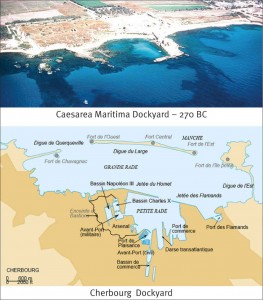

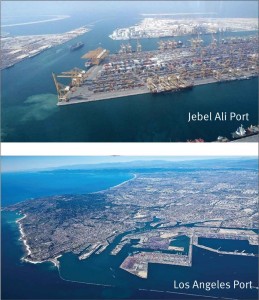

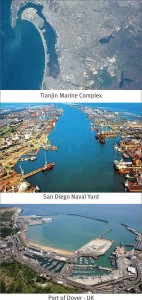

A dockyard must have access to the ocean and sufficient depth of water year round to accommodate the deepest draft of the ship entrusted to its care. Nature has imposed certain limitations where such a dockyard can be set up. Fig. 4 shows all the possible locations for such a yard. The local fractal index plays a significant role when choosing a site. This index represents a ratio of the change in detail compared to the change in scale. A 2-D curve with fractal dimension very near to 1, say 1.1, looks like an ordinary straight line but a curve with fractal dimension 1.95 shows many convolutions or bays through the 2-D space. The geological history, fractal and inland chart survey of a coastline must be examined in depth to ensure the best site list is narrowed. Europe, China, the Americas, UK, the Archipelagos of Greece, Indonesia and the Philippines amongst others, are all blessed with coastlines that have very high fractal indices. Port sites there are readily available. These are often located in bays carved out by deep glaciers flowing out to sea or through volcanic activity in mountains of granite that surface during the evolution of the planet. The Indian subcontinent (shown in Fig. 5) is a very special case as its coastline has one of the lowest fractal indices meaning fewer number of short lines are required for an accurate measurement of the coastline between two points. An explanation for this follows.

This may be an opportune time for the nation to direct its naval architects and engineers to pick up the gauntlet…

When the earth formed, the Indian sub-continent was once part of the supercontinent called Pangaea. About 160 Ma (million years ago), rifting caused Pangaea to break apart into two supercontinents namely Gondwana and Laurasia. The Indian subcontinent remained attached to Gondwana until the supercontinent began to rupture about 125 Ma. The Indian plate then drifted Northward across the Equator towards the already established Eurasian plate, at a rate of up to five centimetres per year. The Tibetan plateau and the Himalayan range resulted when the Indian plate climbed the Eurasian plate. This ascent still continues. Fig. 6 is a good representation of those historic events.

As the subcontinent drifted, the only major forces acting on its shoreline were the resultant flow current, the wind and the vast amount of silt being washed down during heavy rains by the rivers into the basin of the Indian Ocean. These forces only helped to straighten the coastlines thus reducing the fractal index. The volume of suspended sediments from the rivers emptying into the Indian Ocean is the highest of the three main Oceans. Nearly half of it comes from the Indian subcontinent alone. Cones of thickness of over one kilometre are found in the Bay of Bengal and the Arabian Sea. A number of old ports located in the estuaries on the West coast have, with time, fully silted up. Lothal and Surat in the Gulf of Khambat are good examples.

An Alternative Strategy

Historically, Mumbai consisted of an archipelago containing a chain of seven islands adjacent to the mainland. In 1850, the islands were linked up and joined by fill brought in by rail from the present suburbs. After the fill, the site can best be described as being at the sea end of a very wide estuary. The narrow end of that estuary at Thane creek near the mainland serves as a run off for the main branch of the Ulhas River which originates in the Western Ghats.

Around 1735, a shipyard, later called a Dockyard was located on the inside arm of the main island at its Eastern edge and modeled as an extension of a prominent private shipyard at Surat. Since that date, within site constraints, this Dockyard has been expanded in ad hoc spurts. History shows that erosion by the sea, migration of river mouths, siltation of ports and harbours are some of the problems common to all natural ports on the coastline of the Indian sub-continent; the siltation rate being even higher on the Eastern seaboard. Additionally, the continued discharge of sediments and solid waste into the Thane creek from drains and construction activities due to the increasing expansion of the city of Mumbai, has aggravated the siltation problem. The removal of the silt is presently addressed by escalating expenditures for maintenance dredging with little or no enthusiasm for a permanent solution. The colour of the Indian Ocean opposite the ‘Gateway of India’ memorial at Colaba in Mumbai vividly shows the problems the port and the navy face.

Today, the country has the technology and model testing facilities to alter that fractal index and provide the navy with a practically silt-free and sea blue, deep water basin for a naval yard at a site of its own choosing. This can be achieved by extending the coast deep into the sea using sea walls, 25 metres wide at base, made of granite faced interlocked concrete blocks or poured reinforced concrete and dredging the enclosed basin to the outside depth. The production of the blocks can be fully automated. Such a sheltered ‘Artificial Bay’, similar to that shown in Fig. 4, can then accommodate a state-of-the-art dockyard covering roughly about six square kilometres with a frontal sea basin of eight square kilometres. The disposal of the dredged silt in the proposed basin should not be a problem. It can be utilised to extend and raise the mainland towards the sea at the basin lip, for block filling and also for the private development of artificial island cities similar to that shown in Fig. 7. Such a dockyard with its attached naval complex would still be relevant and serviceable two hundred years from now. As a footnote, the world’s longest man-made sea wall which dwarfs this proposal is 33 km long and encloses a bay of 400 sq.km.; fifty times the size proposed herein. That record will soon fall when a sea wall 60 km long is completed.

The shape of any basin and its aspect ratios are critical. Wave energy enters and leaves the harbour basin directly normal to the entrance lines of the wall openings and by diffraction from other directions. Although the wave height distribution in a harbour basin can be predicted by computational fluid dynamics it must, because of the need for accuracy, be verified by precise scale test in a model Wave Basin. Using these tests, the geometry of the basin, orientation of the sea walls and gateway sizes can then be optimally tuned to reduce the wave height and tidal silt under extreme weather.

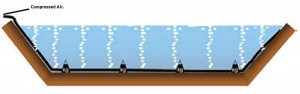

Silt from the monsoon run-off and sewer refuse on the entire naval site will still occur. However, being an isolated new complex, the flow rate and sediment content into the basin can be completely controlled by improved civic discipline, oversized storm drains, fish ponds, silt traps and sewage treatment systems. The building of an artificial harbour is a proven technology refined through time. Aerial views of such harbors built in Roman times to now have been shown in Fig. 8 to 10. Due to stagnation at piers that berth deep draft vessels, residual sludge will have to be dealt with. This is an age-old problem. Fortunately, this can now be easily addressed using an air bubbler system which can be activated occasionally and synchronised to act in unison with the ebb flow. See Fig 11.

A modern independent dockyard can only operate at peak if it has a well educated and trained workforce with outstanding skills…

Conclusion

Dockyards that meet the requirements suggested with their associated naval complex will allow the navy to have the appropriate up-to-date tools needed to ensure it can maintain a modern fleet at a high operational level for many decades to come. The experience gained during this construction could then be the cornerstone for developing a series of island cities by private developers. Such projects, which also result in peaceful territorial gains and a boost for the economy, would help to absorb some of the many million students who graduate each year.

Clouded by the traumatic experiences of some past projects, the difficulties of such mega projects may appear very formidable to the less experienced. Red tape, mendacity and cost overruns have often dogged many projects administered in the public domain. It will be prudent to avoid a repetition of the same. To achieve this, it is suggested that the project be routed through distinct phases. In strict order, these are – preliminary evaluation of potential sites for a naval complex inclusive of the dockyard, Statement of Requirements, concept formulation and selection, Request For Proposal, selection and final specifications, completed system design, detail design and build and warranty.

It is also suggested that a separate professional team review the Statement of Requirements, the final specifications and the deliverables and warranties required for potential conflicts and misinterpretation. Because of the need for brevity, the role of the Military Engineering Services, National Institute of Oceanography, the State Governments and other concerned agencies have not been detailed herein. Suffice it to say that their expertise, cooperation and goodwill are absolutely essential to a program of such importance. They should at the earliest be incorporated into the project network as willing partners ready to share their expertise. Any project of this magnitude is best executed on a fixed price basis with enforceable penalties for delay. Add on costs, often precipitated by an owner – initiated stream of alterations and additions during construction, can be drastically curtailed through a process of pre-planning, accountability and financial incentives.

We now live in fast changing and challenging times that call for bold solutions. Other maritime nations have already shown similar projects can be done successfully and with breathtaking speed in record time. The modernisation of repair facilities proposed will result in better availability of the fleet which could, with time, lead to a reduction of the number of replacement ships required and thus a reduction of capital expenditures. This may, therefore, be an opportune time for the nation to direct its naval architects and engineers to pick up the gauntlet instead of confining them to a career of constrained mediocrity.