A ship designed on a Modular basis, can be checked out in stages using Virtual reality (VR). The necessary inputs for VR are the relevant CAD files. The visual image which is life-size can be then rotated along all three axis and the graphics manipulated in terms of color, shading, scaling, etc. This can be achieved by setting up a full scale VR-3D studio in a central location where each Module or part Module can be studied and inspected in depth by designers, builders, Naval Staff and others. Such inspections will highlight interferences, poor accessibility, inadequate drainage, inadequate removal paths for maintenance, fire risk, radar and sonar cross sections from different views, impossible installations and poor ergonomics. The use of quality control of the design using VR would avoid costly full scale mistakes which invariably lead to large delays and expensive rework which is otherwise quite common in the Industry. A VR studio can also be used to realistically assess the design when exposed to a damage envelope from a prescribed weapon or fire under action conditions. The final user too would be exposed to the design well before it is built. This will facilitate embryonic development of training modules of the crew at a very early stage. Post construction, the VR studio can also be used to graphically display the current state of any part of the ship based on its last known survey. It can also be used to assess a TU. Further, new live images can be created using Augmented Reality (AR) in conjunction with VR.

The use of a CBC makes it exceptionally easy for the Navy to ensure Configuration Management when it has many ships of a single class. For least cost and optimum performance, it is absolutely essential that the Ships of a Class retain their initial similarity throughout their life. This can only be achieved if the standards, spares, maintenance and mid life refits are the same throughout the class. The use of a CBC makes that feasible. Without that, with time, every ship of a Class morphs into a stand alone Class of its own thus creating a series of escalating logistic problems which in peace time get swept under the rug but invariably later, under action conditions, get exposed.

The use of a CBC makes it exceptionally easy for the Navy to ensure Configuration Management when it has many ships of a single class. For least cost and optimum performance, it is absolutely essential that the Ships of a Class retain their initial similarity throughout their life. This can only be achieved if the standards, spares, maintenance and mid life refits are the same throughout the class. The use of a CBC makes that feasible. Without that, with time, every ship of a Class morphs into a stand alone Class of its own thus creating a series of escalating logistic problems which in peace time get swept under the rug but invariably later, under action conditions, get exposed.

From time to time, many expressions pertinent to Modular design have been used by the Shipbuilding Industry. Some of these are listed below to enable readers to have a better appreciation of what they represent:

- Payload limited: The payload which are the Weapons & Command and Control will be Modular based without any size restriction but limited to a chosen Platform.

- Payload volume limited: The payloads Modules are additionally restricted to a particular volumetric size (Containers) to facilitate quick interchange between ships whilst maintaining cross Platform commonality.

- All systems: Every system on the Platform will be Modular based; some may even be volume limited. This would result in the lowest maintenance costs and building time whilst stimulating competition among the system specialists.

- Function segregated: All systems pertaining to individual main functions are Modular but distinctly and strictly segregated into sequential blocks like Oilers and Bulk carriers. The ship then mainly consists of segments; each segment with a specific functions like seen in nature. With the recent break through in super-conductivity, a function segregated, segmented all Electric Destroyer is now feasible. It is a trend that is gaining momentum.

- Reserve capacity: Often a choice has also to be also made if the design is to have reserve allowances. Reserve capacity required at the Platform level could be reserve wire way capacity, reserve pipe bank capacity and the ability to accommodate an added parallel mid body block in an alternate version, etc. Reserves at the Module level have to be fully detailed in one or more of the interface specifications and these could include areas, volumes, power and other services which have to be provided for to handle any technology refuels and even half life updates.

There are also other fundamental questions that must be addressed if the full benefits of Modular design are to be realized: These are set out below:

- Is the Architecture of the Platform and its systems to be open based or closed? This single decision will have the biggest impact on cost and time. Most politicians, and bureaucrats have little understanding of this very important parameter that affects costs. Open systems are systems that rely on technologies that are currently in use in the Industry. Closed systems are systems specifically designed for the client. It is a fact that Open systems encourage better competition, a faster rate of improvements and the cheapest end products. This is a fundamental question which must be addressed prior to formulating other details. The trend is towards the use of Open systems since full shock hardening to realistically meet the shock load spectrum of modern weapons can be economically overwhelming. As the shock intensity of weapons has grown by leaps and bounds, the shock spectrum used by most designers is most often out dated for the weapons now in use. This is especially so when it takes a decade between keel laying and delivery. Actual correlation and deficiencies can only be established by extensive trials on a shock range and analysis of survival from current battle conditions at time of delivery. It often makes no sense to excessively proof harden some particular equipment when statistics indicates platform survival in battle is increasingly low.

In service Technical Divisions invariably increase the costs of Capital projects by making unwarranted and unrealistic demands in specifications tailored by them. Managers in Industry are then quick to turn such demands into extravagant cost overruns. The old monopolies created by closed systems are not easy to replace. Being very lucrative, they have a very strong in house and an external lobby support base. The choice has to be a client based decision and not one that can be decided by the designer. Huge savings can be made by intelligent and valued use of open systems.

In service Technical Divisions invariably increase the costs of Capital projects by making unwarranted and unrealistic demands in specifications tailored by them. Managers in Industry are then quick to turn such demands into extravagant cost overruns. The old monopolies created by closed systems are not easy to replace. Being very lucrative, they have a very strong in house and an external lobby support base. The choice has to be a client based decision and not one that can be decided by the designer. Huge savings can be made by intelligent and valued use of open systems.

- Will the ship procurement be single sourced (a single Builder) or Group sourced to a consortium? A consortium must include separated and distinct expertise in Project Management, design, test facilities, specialist Module/Block building and assembly of the different Blocks/Modules. A group sourced procurement will be the fastest and will encourage development of system oriented Module builders because of direct participation. It decouples the ship, system design and their production whilst reducing the cost of maintenance, technology refreshes and half life updates. It is the preferred route.

- Can the specialist Module builders build, handle and store their associated steel work under covered conditions and assemble incoming modules into Blocks? This is most desirable as it means less time spent in fabrication and installation at the Assembly yard. Tests, trials and inspection related to the Module and the associated Hull can then be carried out prior to its shipment to the Assembly yard.

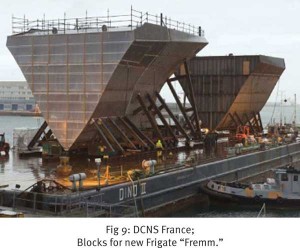

- What is the largest Block size that they can safely handle? The larger the size, the less is the time spent in the Assembly yard. Unnecessary delays occur due to misalignment of adjacent Blocks, incomplete interfaces and poor Q.A. In the world market, current Block sizes are +2000 Tons for a Cape Ore, +1000 Tons for Carriers and +600 Tons for smaller ships. Blocks are steadily increasing in size. Assembly yards doing general steel construction have done crane barge lifts of 11,600 Tons representing Bridge/Platform sections destined for large infrastructure projects.

- How will the inspections, tests and trials including thermal testing, noise, vibration test, sonar ranging, Radar imaging, I.R and shock testing be conducted by the Module builders? The evaluation of all such facilities and their established performance must be established and documented by an independent Technical audit prior to any project.

- What is the capacity of the Assembly yard to assemble and safely store and maintain incoming Modules/Blocks and also build non specialist ones?

- How will the tests, trials and inspections of the finished Platform (similar to those above for a module) be conducted and by whom? This is best undertaken by the Project Team who must always have the final say. The comments in respect of Module trials above are also applicable for the Platform. Public release of actual trial data based entirely on ratios indexed to unit coefficients ascribed to the targets in the Statement of requirements helps to establish the credibility of the many claims often made by designers/builders and the superlatives that usually follow. To-date, such information together with total life cycle costs is not freely available.

The capacity of the specialist Module builders are easily established by doing a functional analysis of the ship and its systems, evaluating the suppliers available and their past performance to build similar modules. In addition to assessing their technical competence for the particular system, they should have adequate covered shop facilities, handling and lifting arrangements to build, handle and store the largest Block size or Module they wish to build. The transport /handling storage, launching and berthing arrangements at such Module/Block Builders and the Assembly yard under extreme conditions including the hundred year seismic and environmental load spectrums at each site needs to be carefully evaluated and signed off by the Underwriters for the maximum size, berthing, launch-ways, trigger loads on dagger foundations, erection loads and the lifts envisioned. At public enquiries after an incident, it has been my experience that most of these records are never found possibly because they never existed in the first place. An evaluation of the 3-D security and firefighting capacity at each site is also necessary to complete the assessment.

The capacity of the specialist Module builders are easily established by doing a functional analysis of the ship and its systems, evaluating the suppliers available and their past performance to build similar modules. In addition to assessing their technical competence for the particular system, they should have adequate covered shop facilities, handling and lifting arrangements to build, handle and store the largest Block size or Module they wish to build. The transport /handling storage, launching and berthing arrangements at such Module/Block Builders and the Assembly yard under extreme conditions including the hundred year seismic and environmental load spectrums at each site needs to be carefully evaluated and signed off by the Underwriters for the maximum size, berthing, launch-ways, trigger loads on dagger foundations, erection loads and the lifts envisioned. At public enquiries after an incident, it has been my experience that most of these records are never found possibly because they never existed in the first place. An evaluation of the 3-D security and firefighting capacity at each site is also necessary to complete the assessment.