“It’s all right to aim high if you have plenty of ammunition.” — Hawley R. Everhart

The current stand-off at the Line of Actual Control (LAC) has once again highlighted the fact that despite advances in technology, modern wars in our context will still need highly trained soldiers to engage in close combat. In such a situation, there is a requirement of large quantities of high quality general munitions to rain fire and fury on enemy forces and neutralise, suppress and unhinge him. Security in supply of general munitions is, therefore, going to be of enormous operational significance for India. General munitions are defined as those munitions that do not require complex maintenance interventions and the technology is primarily based on chemistry and mechanical engineering. These are categorised as small arms ammunition, medium and heavy calibre munitions, general explosive stores and pyrotechnics. Medium and heavy calibre munitions are the areas where for quite some time, safety and quality issues have surfaced.

Energetic materials give munitions the ability to propel and destroy. Energetic technologies are the most critical of technologies in general munitions as these determine the performance, safety and life of munitions. It should be least susceptible to accidents and least vulnerable to external stimuli such as heat, shock and impact. It is of paramount importance that indigenous munitions are designed and manufactured to be safe and risk free. The Indian Army, in particular, has been raising concerns about the safety of ammunition being produced by the Ordnance Factories (OFs). In an internal assessment carried out, it was noticed that between 2016 and 2019, a total of 403 ammunition accidents had occurred, fatal in a number of cases. Approximately, Rs. 960 crore worth of ammunition had to be discarded due to poor quality and safety issues.

The recent move of the Defence Ministry according approval for indigenous development and production of 125 mm Armour Piercing Fin Stabilised Discarding Sabot (APFSDS) ammunition for T-72/T-90 tanks by the industry is indicative of a desperate attempt by the Indian Army to broaden the base of ammunition supplies. However, in the absence of a coherent long term approach, the present move will result in all players missing the fairways for the woods. The track record of indigenous development in general has not been encouraging, as a concrete strategy is yet to be devised. A Munitions Vision that ensures a sustainable and secure supply of general munitions while providing the best value for money is the key to this strategy. It needs to be based on a cooperative and collaborative framework involving DRDO, OFs, the armed forces and the private sector, with sharing of foundational knowledge and hand-holding. This is perhaps the only way to reduce dependence on import of large stockpiles of ammunition and bank on indigenous production. Dependence on other nations for general munitions, as is the case presently, is not advisable from the national security perspective.

System Design and Development

For India, it is important to consolidate the existing capability to design and manufacture munitions, the responsibility for which is primarily with the DRDO and OFs. No amount of criticism by the military can take away their stellar achievements in meeting with the requirements of the armed forces in previous wars and the ongoing low intensity conflict. The current drift has been due to absence of purposeful modernisation, loss of expertise consequent to retirements and inability to focus on futuristic technologies related to safety, performance, life and environmental impact. There is a need to upscale capabilities in modelling, material characterisation, testing and evaluation. We have to develop a substantive fill, assemble and pack capability within the industrial base. In addition, forging and manufacture of specialist steel is critical.

It is vital that a life-cycle management capability is created to include technical management, proof testing, concurrent surge capability, storage, safety and disposal capability based on international best practices. In the past, several quality claims on ammunition procured from abroad had been rejected by the OEMs stating that the testing protocols being used in India were not acceptable to them. It is important to establish an integrated testing and evaluation capability so that we can not only understand and interpret test results of others but also configure testing to meets our safety and performance standards. Capabilities to predict safe and operational life using ageing and failure algorithms, effects and consequences modelling, recover, recycle and re-use technologies are niche areas of munitions through life management and need to be incubated.

During my interaction with Russian designers on barrel burst cases of tank guns, they were of the opinion that the process of technology absorption in OFs was flawed. It was observed that, in most cases, the OFs ended up procuring raw materials from all corners of East Europe in pursuit of lowest cost (L1) quotation. If propellants and explosives are procured from L1 sources, it is difficult to guarantee stipulated safety and consistency standards, due to difficulty in accurately assessing the expired shelf life of energetic materials. In my opinion, the root cause of faulty ammunition manufacture in India has been the incomplete absorption of technology, lack of self sufficiency in energetics and a cultural inability of the ageing workforce to adhere to the stringent processes outlined in technology documents. Taking shortcuts is our weakness.

Armour Ammunition

The capability of attack on armour is the most complex and dynamic area of ammunition design. Defeating a tank entails penetration of the armoured envelope accompanied by violent secondary effects to disable the crew and platform. The Russians were the first to field a tank gun firing APFSDS ammunition. It had a lot of similarities with the German ammunition Peenemunde Arrow used in World War II. The 125 mm gun of T-90 and T-72 tanks is a product from the same designers. The current ammunition being used has a penetration of 450 mm of Rolled Homogenous Armour (RHA) steel. What is being asked from the industry is enhanced penetration of 530 mm, to be fired from existing barrels.

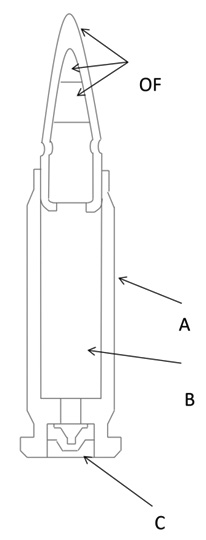

Fig 1: APFSDS Ammunition

In 2014, the government had entered into a contract with Tecmash, a Russian company for the supply of some 60,000 rounds of APFSDS ammunition, nicknamed Mango with a penetration of over 500 mm (Fig. 1). It was accompanied with technology transfer to the OF. The Indian Army has been complaining of the unacceptable quality of ammunition being supplied and, therefore, is looking at alternative sources of ammunition procurement. However, this band-aid approach appears to be ill-conceived as foundational knowledge to develop complex tank ammunition is not there in the private sector. In the short to medium term, continued access to bespoke ammunition, preferably under technology transfer is essential to maintaining operational readiness. Any indigenous effort at enhancing penetration should be under the aegis of the Defence Research and Development Organisation (DRDO), the only agency having a sound knowledge base on ammunition design and testing.

Development of APFSDS ammunition involves advanced sabot technology to achieve higher penetration. For increased penetration, the sabot mass has to be reduced and penetrator length maximised. Higher stresses could lead to failure of sabot and the penetrator breaking up immediately beyond the gun barrel (Fig. 2). Future penetrators could be 15 percent longer, 8 percent faster, yielding 22 percent more penetration (around 825 mm of RHA) compared to the state-of-the-art tungsten rod penetrator. A thorough understanding of gun design and improved materials is the key. A tank gun and ammunition is designed as a system keeping in mind the targets to be defeated. In the absence of gun design details, the ability of the private sector to develop, not only complex ammunition, but with enhanced capabilities, is questionable.

Fig. 2: SABOT And Penetrator Separating Beyond Gun Barrel

Tubed Artillery Ammunition

Guns, mortars and rocket ammunition are another important area where it is indispensable to acquire the capability to design and develop a family of munitions to include more effective charge system, projectiles and fuses. The current suite of capabilities is 30 to 40 years old and quality and safety has become a matter of concern on account of over 80 accidents in the past five years. In fact, these designs have outlived their initially planned service life. It is, therefore, critical that a de novo look is taken from the safety and vulnerability angle and bespoke ammunition is developed using new design methodologies, good engineering practices and high quality manufacture. Moreover, with new 155 mm gun systems being inducted or under evaluation, it is important to develop a new suite of 155 mm ammunition for various platforms where safety and minimal collateral damage become the new norms of design, making them what is now categorised as ‘Insensitive Munitions’. The current ammunition is in fact retarding the indigenous development of guns because of ammunition safety issues. Similarly, the 105 mm light field gun can be provided an improved High Explosive round which is lethal and cost effective as this gun is likely to be in service for the next 20 years or so. Science and technology skills to design and develop these capabilities as well as an understanding of the interface between the weapon and munitions, is available only with the DRDO. It alone has the capability of assessing the desired effectiveness and possible consequences of using a weapon – munition combination. Such operational analysis tools have been painstakingly created over a period of time and no OEM is going to share these with the private sector.

Small Arms Ammunition (SAA)

SAA comprises ammunition for pistols, rifles, machine guns, anti-material and sniper rifles, automatic grenade launchers, mortars, rocket launchers, cannons and such other systems. This is one category of general munitions where the requirements are large and technology, tools and processes simple. There is large scope for the private sector in manufacturing here either through supply of components or manufacture of full rounds. The global demand of SAA is over six billion rounds per year and rising. It would be good if the government passes on to the private sector validated design methodologies, good engineering practices and high quality manufacturing processes it has incubated over the years and facilitates private industries to take up the design and development of small arms and munitions as a system to meet with futuristic requirements. In the long run, the government should only retain surge capability in SAA and a national capability to understand critical design and development parameters, understanding of internal and external ballistics, accuracies issues, packaging, final assembly, safety and arming issues. The volumes being large, one expects that the private sector will quickly build a robust fill, assemble and pack capability along with a reliable indigenous supply chain, to enable the armed forces to cut down stockpiles and save on life cycle costs.

In the case of 5.56 mm ball ammunition where the requirements will be large in the foreseeable future, a cooperative model can be adopted. Fig. 3 explains how even in case of this relatively simple product, a collaborative work share between the OF and private production entities (A, B, C) can be configured. It can then be rolled forward for more complex munitions. Operating ammunition plants under Government Owned Contactor Operated model is another pragmatic option, to build foundational knowledge in the private sector.

Pyrotechnics and Explosives

There is huge variety of pyrotechnics and explosives where there is private sector participation but issues of safety, age, obsolescence, primitive manufacturing practices remain. A focus on advanced pyrotechnics such as IR and RF decoys is essential. Manufacture of mines is an area which can be handled by private entities, the aim being to bring down stockpiles and rely on surge production. Advanced area denial techniques and counter mobility technologies are the emerging areas of capability development.

Strategic Partnership

It is important to have a Munitions Vision and lay out a long term strategic partnership plan for acquiring self-reliance in this critical area. The import ban list could be taken as the indicative requirement in the short term. In the past 70 years, a fair amount of skills and competencies (common technologies) have been created with DRDO and the OFs. It needs to be consolidated into a state-of-the-art capability by acquiring priority technologies and drivers. The private sector has to receive this foundational knowledge through cooperation at the sub-system level. Acquisition of this foundational knowledge from OEMs abroad will entail prohibitive costs and will be accompanied with critical gaps in know-how as has been the case with the OFs. A pragmatic approach will be to allow private sector participation during ammunition manufacture at the OFs.

The joint development of the indigenous COVID vaccine, COVAXIN wherein a national capability, National Institute of Virology, ICMR and a private entity Bharat Biotech collaborated to develop the vaccine is a stellar example of the capabilities of our human resources given a facilitative environment. The government assumed the role of a Planner, Investor and a Customer. It is through such similar models that Atmanirbharata in defence can be turbocharged – leadership by the government knowledge-based institutions and partnership by industry.

The Way Forward

The available knowledge cache on design, development, testing and evaluation of munitions within the country needs to be designated as a national capability and made accessible to the private sector on a need basis. Gaps in this capability can be filled through innovation and partnerships with foreign OEMs. To take the Munitions Vision forward, a special task force of experts may be assembled under the Defence Ministry, possibly under the Chief of Defence Staff (CDS) with a long term plan to set course and make things happen. It should be empowered to create a DARPA-like effect through innovation and maximising participation of the private sector. As they say, action without strategy could end in a nightmare and the essence of a strategy is in choosing what not to do. Merely leaving it to market forces may not be of consequence, neither cost nor combat effective.