Very few companies in the world can claim to have mastered the art of producing high-performance military engines and most of them are in the United States and Europe. Russia and Europe lag behind the US in military aerospace technology. China is accelerating its efforts to produce modern military power plants and considering its steely determination and huge investments, it should develop indigenous capability to reckon with in around two decades. As for India, its frustrating experience with the Kaveri engine has shown that designing and manufacturing an engine incorporating cutting edge technology for a combat aircraft is not easy, even for a nation well advanced in space and nuclear regimes.

Creating an aero engine for an air superiority fighter jet or a heavy-lift transport plane or a light attack helicopter is no child’s play. The demands of combat performance are far more taxing than those of commercial ones. Therefore, engine designers are constantly confronted with newer and tougher challenges. Production also requires advanced techniques and extensive automation to ensure consistent quality and reliability. The tens of thousands of parts that make up an engine have to be fashioned to exacting tolerance, down to a few microns. An ordinary turbofan blade, for instance, must perform without significant deflection despite being subjected to heat that exceeds the melting point of most metals.

…Creating an aero engine for an air superiority fighter jet or a heavy-lift transport plane or a light attack helicopter is no child’s play…

Consequently, very few companies in the world can claim to have mastered the art of producing high-performance military engines and most of them are in the United States and Europe. Russia and Europe lag behind the US in military aerospace technology. China is accelerating its efforts to produce modern military power plants and considering its steely determination and huge investments, it should develop indigenous capability to reckon with in around two decades. As for India, its frustrating experience with the Kaveri engine has shown that designing and manufacturing an engine incorporating cutting edge technology for a combat aircraft is not easy, even for a nation well advanced in space and nuclear regimes.

Advanced engines are built mainly with high-strength materials such as titanium, nickel, aluminium, and super-alloys based on nickel and cobalt that can withstand extremely high temperatures. Lightweight composite materials are becoming all the rage in aircraft manufacture and are quickly finding their way into power plants as well. They are extremely strong and durable and can be fashioned into complex shapes. Military engines must be capable of withstanding the most trying conditions including high temperatures, high speeds, rapidly varying altitudes, intensive manoeuvring, rapid and frequent changes in throttle settings.

Military power plants may be divided into some major categories – low-bypass turbofans that generally power fighter jets; high-bypass turbofans that propel large transport aircraft, flight refuelling and other large military aircraft; turboprops that are employed on more lower-speed, smaller transport and surveillance aircraft and turbo shafts typically used on helicopters.

While military and commercial jet engines often have very different performance requirements, the materials and construction techniques used to make key components such as the engine core are in many cases quite similar. For instance, Pratt & Whitney’s F117 dual-spool high-bypass turbofan engine that powers the Boeing C-17 Globemaster III military transport aircraft, which is expected to join the IAF early next year, is a close derivative of its PW2037 commercial engine fitted on the Boeing B757. With military aviation getting ever more technologically complex, what does the future hold for aero engine development?

Fighters of the Future

The resources required to produce modern combat aircraft are so huge that only the US has been able to field a fifth-generation fighter, the combat-proven F-22 Raptor. But even the world’s richest and most powerful nation is not immune to shrinking defence budgets and realises that aircraft must not just be affordable to buy but operate economically during their entire lifetime. And that depends mainly on aero engines.

“We have run out of money, so now we must think,” was the frank admission of United States Air Force (USAF) Vice Chief of Staff General Philip Breedlove last July. For this reason, even the prestigious Lockheed Martin F-35 Lightning II, the most expensive weapons programme in history, is facing major production cuts. In November, Switzerland picked the JAS 39E/F Gripen as its new fighter over the Eurofighter Typhoon and Dassault Rafale, not because it was the best but because it met its requirements at the lowest price. This trend does not yet seem to have touched the IAF, which recently shortlisted the two most expensive combat aircraft and dumped the more economical Gripen.

Fighter jet engines are probably the most highly-stressed machines on the earth. Apart from take-off and recovery the engines of a transport plane or tanker generally run at fairly steady parameters for most of a flight. However, a fighter aircraft engine is routinely exposed to extreme speed changes, sometimes from maximum power to idling and back to maximum in a matter of seconds as pilots frequently and rapidly alter throttle settings during high-intensity combat manoeuvring. This means equally rapid temperature changes (or thermal cycling) that can trouble even the most rugged engine. A stark example is of the USAF’s experience with the Pratt & Whitney F100 engine which powers the F-15 Eagle and F-16 Fighting Falcon. This afterburning turbofan’s service life reportedly turned out to be 30 per cent lower than expected because it was subjected to more than five times the number of full throttle transients it had been designed for.

Military engines must be capable of withstanding the most trying conditions…

For all their complexity and sophistication, fighter engines are not always efficient. They operate best at rather limited optimum parameters; any time they enter a different regime their performance drops, sometimes drastically. But fighters of the future will have a new kind of jet engine – a variable-cycle turbine that can run in at least two modes, one for high speed and one for fuel efficiency. They will be more fuel-efficient by shaping the air flow at higher compression levels than ever. This is crucial if the USAF is to meet its ambitious goal of reducing fuel burn in existing aircraft by five per cent by 2016, ten per cent by 2020 and 20 per cent by 2030. Other operators too would surely covet such fuel-efficient engines.

In 2007, the USAF selected General Electric and Rolls Royce to demonstrate next-generation engine technologies under two futuristic research initiatives, the Adaptive Versatile Engine Technology (ADVENT) and the Highly Efficient Embedded Turbine Engine (HEETE) programmes. Both are heavily dependent on software. Since many performance parameters can be fine-tuned using software, it is becoming an increasingly vital aspect in aero engine design. Most modern engines are fitted with Full Authority Digital Engine Control (FADEC). GE claims its HEETE design may achieve Overall Pressure Ratios (OPR) up to 70:1. In contrast, the Pratt & Whitney F135 that is fitted on the F-35 Lightning II, claimed to be the world’s most powerful fighter engine, has an OPR of around 30:1. And Pratt & Whitney’s PurePower PW1100G Geared Turbo Fan (GTF) engine that is due to power the Airbus A320neo is credited with a top OPR of 50:1. Pratt & Whitney is also believed to be quietly working on its future PW9000 engine, a combination of the best features of the F135 and the PurePower GTF. It is expected to have significant fuel burn improvements and extend the range and endurance of any platform it powers.

Fighter jet engines are probably the most highly-stressed machines on the earth.

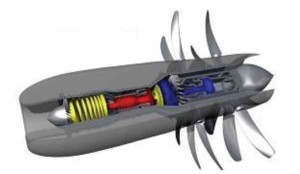

The goal of ADVENT is to develop an efficient variable-cycle engine in the 20,000lbf (89 kN) thrust class for next generation military aircraft. Operational testing is slated to begin sometime next year. The engine was originally expected to power the USAF’s next-generation bomber but since the bomber programme is itself in doubt, Rolls Royce predicts that the aero engine will be better suited for a potential 2020 engine upgrade for the F-35 Lightning II. A key objective of ADVENT is to introduce a third duct for bypass air around the engine core, which is expected to reduce Specific Fuel Consumption (SFC) at high speeds. Clearly, even for fighter engines, the days of brute power are coming to an end and fuel efficiency will assume increasing importance.

Military Transports Go Civil

Till quite recently military engine makers did not feel too constrained by the noise and emissions limitations that apply to civilian manufacturers. But military aircraft especially transport planes, are now beginning to feel the heat of the green brigade. Last year, Europrop International secured civil type certification for the TP400-D6 turbo-prop engine powering Airbus Military’s under-development A400M large transport aircraft that is slated for first delivery next year. It is claimed to be the first large turbo-prop engine to have been certified by the European Aviation Safety Agency (EASA) and the first military engine to have been certified by the EASA to civil standards from the outset – a trend is only likely to intensify.

Indeed, environmental and fuel-economy pressures may force revolutionary changes in turbofan engine architecture, whether military or commercial, within a decade or two. The ceaseless quest for greater efficiency means that engine bypass ratios and fans will continue to grow in size. This, however, makes it more difficult to fit engine to airframe without increasing the weight of the engine mounting and consequently, the wing itself. Higher pressure ratios and higher temperatures, are also necessary to obtain maximum thermal efficiency from an engine core making it more challenging to ensure a long engine life. How technologists choose to resolve these conflicting issues remains to be seen.

The category of next-generation commercial power plants (N+1) due around 2015 is led by Pratt & Whitney’s PurePower GTF engine and CFM International’s Leading Edge Aviation Propulsion (LEAP-X) turbofan. Both promise reductions in fuel burn of around 15 per cent that should be particularly attractive to military planners for extended range operations. The GTF’s unique gearing system enables the fan to rotate at relatively low speed while the low pressure compressor and turbine operate at higher speed. This increases overall engine efficiency and reduces fuel burn, emissions and noise. The LEAP-X, on the other hand, is a more conventional design that employs composite materials, next-generation 3D aerodynamics and low-emissions combustion techniques in the engine’s hot-section (core) to cut fuel consumption.

By 2025, second-generation engines (N+2) could bring a further 10 per cent reduction in fuel burn by increasing pressure ratios even more, and also by increasing the bypass ratio to about 18 to 20, which may mean significantly larger fans. That is when the familiar tube-and-wing configuration of commercial and military transport aircraft will be approaching its limit of advancement, at least with the existing engine architecture. The best turbofan engines of today can extract around 40 per cent of the potential energy of aviation fuel. A new generation of gas-powered turbofans still under development, featuring variable-bypass flows and ultra-high pressure ratios, may be able to convert between 55 per cent and 70 per cent of the energy of the fuel into useful thrust. Such variable-cycle engines will probably lie near the peak of gas turbine efficiency and be tailor-made to burn alternative agro-based fuels.

Environmental and fuel-economy pressures may force revolutionary changes in turbofan engine architecture.

Aero engine makers have not revealed much about how they hope to continue boosting propulsive and thermal efficiency in 2035, the third-generation (N+3) timeframe. If power plants are to become even more fuel-efficient, designers need to progress beyond gas turbines. Among other things, GE is studying alternative “highly integrated” propulsion methods such as hybrid turbo-electrics and thermal efficiency improvements including ceramic matrix composites and advanced metallics to allow engines to run even hotter. It expects that by 2035, half of the typical jet engine could be non-metallic. Pratt & Whitney is likely to pursue larger and larger bypass ratios for GTF engines while CFM International and Rolls Royce are more likely to choose open-rotor (also known as propfan) designs. Open-rotor engines will probably be employed on military transport aircraft before civilian airliners because their dramatically higher fuel-efficiency comes with the penalty of extra noise, not a major problem for military engineers familiar with high decibel operations.

Till now, airframes and engines were generally designed by separate teams working independently, often in different aerospace companies. In future, a single team may need to work on airframe and engine simultaneously to get the best out of the combination. Composites are making aircraft structures lighter while winglets and laminar-flow techniques are being employed to facilitate smoother airflow but such techniques cannot be employed forever. The next stage in the transition may be to unconventional designs such as blended-wing bodies. Northrop Grumman’s flying-wing concept, for instance, is likely to find employment in a military transport role before it is adapted to the commercial industry. It is expected to reduce noise, emissions and fuel burn dramatically with the advanced propulsion system providing 20 per cent of the overall improvement. Key design features include composite wing, advanced inlets, embedded high-bypass engines, automated manoeuvre load alleviation and carbon-nanotube data cables.

Much further into the future, the supersonic combustion ramjet engine (or scramjet) may be a potential aircraft power plant. Scramjets rely on the vehicle’s forward flight to compress and decelerate incoming air before combustion, with supersonic airflow taking place through the entire engine. Since they have no rotating parts, scramjets are easier to make and maintain. They may be capable of flight at more than five times the speed of sound, perhaps even spaceflight. However, their practical utilisation is still some decades away. Once again, their military exploitation will probably precede civilian use.

Helicopters Still in Hover

When it comes to military helicopters, most designs are already 30 to 50 years old. Even the US Army’s Boeing AH-64 Apache twin-engine advanced attack helicopter has been around for about three decades. Helicopter pilots often yearn for a bit of extra speed but spurring these versatile yet sluggish machines beyond a cruise speed of about 150 knots presents substantial cost and engineering complications. Helicopters are speed-challenged not because of any deficit of engine power but due to a vexing aerodynamic phenomenon called retreating blade stall. One promising solution to the problem has been offered by Sikorsky’s X-2 technology demonstrator that achieved an unofficial rotary wing level speed record of 253 knots in September 2010.

For all their complexity and sophistication, fighter engines are not always efficient…

The X-2 is due to morph into the Sikorsky S-97 Raider by 2014. With twin coaxial rotors that spin in opposite directions and a tail-mounted pusher propeller the S-97 Raider will be able to cruise at speeds of up to 220 knots and may boast of a top speed of 240 knots. Sikorsky also claims it will provide dramatic improvements in manoeuvrability, range, endurance, altitude and hover capability. This prospective US Army helicopter will be fitted with General Electric’s YT706-GE-700R, a 3,000-shp class turbo-shaft engine with FADEC.

Helicopter engines are also ripe for an efficiency boost. In the pipeline is the GE3000 for the US Army’s Improved Turbine Engine Programme (ITEP), planned as the next-generation 3000-shp class engine for medium-lift applications. General Electric has also been selected to develop technologies for a 5,000-10,000-shp class turbo-shaft/turbo-prop engine for the Future Affordable Turbine Engine (FATE) programme. Besides higher power for increased hot-and-high payload and performance, the programme targets extended range and endurance. FATE’s goals are rather impressive: 35 per cent reduction in SFC, 80 per cent improvement in power-to-weight ratio, 20 per cent improvement in design life and 45 per cent reduction in production/maintenance costs. Affordability and efficiency indeed hold the key. These gains will be achieved with the help of advanced aerodynamics, sophisticated cooling configurations and improved materials.

Change in the Air

There is little doubt that military engines of the future will be lighter, more efficient, cleaner and quieter. Both compression ratios and combustion temperatures are expected to achieve significant increase. Computational Fluid Dynamics tools will increasingly be used to design optimised 3D aerodynamic shapes for compressor and turbine blades, stator blades and intake and exhaust shapes. Higher combustion temperatures will be achieved by employing ceramic matrix composites, advanced turbine alloys, thermal-barrier coatings and adaptive engine cooling. Improved design quality and production quality (i.e. of material tolerance) will be manifest in growing thrust-to-weight ratios. The engine core will continue to shrink and a lighter engine means the wing can be thinner, leading to even more weight reduction.

Fuel efficiency already tops the list of the most sought after technologies for engines, civil or military. Fuel is a major item of military expenditure (overtaking even personnel costs in some cases) and the price of oil can only increase. Even a two per cent reduction in fuel burn may translate into huge savings when calculated over an entire fleet. Lower emissions, greater reliability and reduced operating costs will also be increasingly important attributes of military power plants. Key items on the maintenance wishlist include on-wing reliability and ease of replacement and repair. For instance, a complete change of the TP400-D6 turbo-prop engine fitted on the Airbus A400M will be possible within four hours. Maintenance downtime should also become shorter and less frequent, with major overhauls perhaps not before ten years. Last but not least, all these attributes will hopefully come at a lower price.

After the feverish pace of military aircraft and engine design during the Cold War, development work slackened during the 1990s and has not quite picked up again. The long-lasting economic woes of the world’s most technologically advanced nations mean that many military research programmes may be wound up or proceed in slow motion. There is a noticeable cooling of enthusiasm in the US government, for instance, for the F-35 Lightning II programme. It is not yet clear when or if there might be a sixth-generation fighter jet to replace the F-22 Raptor after 2030. The reason is not far to seek. The US, which has always been averse to taking casualties, is increasingly relying on Unmanned Aerial Vehicles (UAVs) to accomplish many of the missions hitherto entrusted to manned combat aircraft, without risk to its pilots and at far lower cost. Israel, another leading exponent of air power, seems to have adopted the same tack. That is why it is not unlikely that the current “fifth generation” combat aircraft may come to be called the “last generation”.

Everyone loves what you guys are up too. This type of clever work and reporting!

Keep up the wonderful works guys I’ve added you guys to my personal blogroll.