Everyone on the streets today is talking about globalisation. In military circles, there is much talk about Revolution in Military Affairs (RMA). The military is also going full steam ahead on hardware acquisitions, but when it comes to Revolution in Military Logistics (RML), most, particularly in the military circles, are in a denial mode. The intention here is to try and bring about a change in outlook on this very important area that is taken for granted.

Raison D’etre

The raison d’être for any military logistic system is to ensure that the correct item and service is provided to the end user, at the right time, place, and in correct quantity and quality required for the situation.

Indian Armed Forces have, however, continued to grow, basically under the same original framework. One major restructuring was attempted post Kargil War. Even that has remained still-born due to lack of political will to appoint the Chief of Defence Staff (CDS).

In the final analysis, most military campaign failures, could be attributed to mismatch between the operational plan and the logistic support capabilities. This could be well illustrated with examples of over-stretched logistics, from world military history.

In context of integrated logistics, the weakest chink in the Indian armour today is that of the Army. It must first achieve intra-service integration. To enable that, the most essential prerequisite is the computerisation of the logistics. This should be accompanied in parallel by restructuring of the overall organisation.

This by no account means that the present set up is not delivering. What it means, is, that by restructuring, the future challenges could be met more effectively, speedily and efficiently, both in material and human terms.

At the same time, and inspite of serious handicaps, the most encouraging part, is that the Army, seems to be the most open and willing service to take on this challenge.

In this context, the Navy and the Air Force are far ahead of the Army. They have kept pace with each other in bringing about organisational changes linked to RML. The Air Force is perhaps a hair-breadth ahead in the conventional logistic management arena. But in the Capital Acquisition and Weapon Platform Development Management – the Navy is way ahead.

The need of the hour is to work in unison and share one’s experience and expertise to move forward.

Overall Indian Situation

At the time of Independence, the Indian Army, the Navy and the Air Force, inherited their organisational structures from their respective parent service in UK. Since then, the British system has undergone a sea change.

Indian Armed Forces have, however, continued to grow, basically under the same original framework. One major restructuring was attempted post Kargil War. Even that has remained still-born due to lack of political will to appoint the Chief of Defence Staff (CDS).

Also read: Chinese avionics & missiles for Pakistan

In this context, it is essential to look at other models and draw suitable lessons, appropriate to the Indian environment. In this regard the National Security Council Directive–2000 is relevant.1

The British System

In the last fifty years the British system has undergone series of changes in the following sequence:-

In the last fifty years the British system has undergone series of changes in the following sequence:-

- Introduction of computerised logistics management.

- Integration of all intra-service activities on conventional logistics.

- Corporatisation of repair infrastructure – till then, an in-house service.

- Privatization of repair infrastructure followed by outsourcing of other support infrastructure.

- Integration of all inter-service logistics, under broad heads of Defence Logistics Organisation (DLO) and Defence Procurement Agency (DPA).

- Merger of DPA + DLO + Defence Commercial Service Agency (DCSA) into Defence Equipment & Support Agency (DE&SA) – with the Chief of Defence Material (CDM) in charge, as a four star General/equivalent.

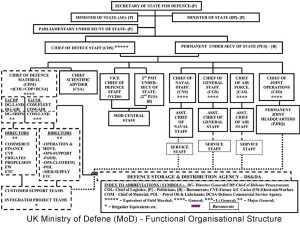

The functional chart of CDM is illustrated in the figure.

It would be observed that the organisation has two major Divisions.

- One dealing with capital acquisitions. This is subdivided on functional basis into DG Ships, DG Submarine, DG Combat Aircraft, DG Land Equipment etc. The next level is illustrated, using DG Ships as an example.

- The second Division – deals with support infrastructure – with three Chief of Material (COMs) in the rank of three-star generals heading their respective service support division.

The overall MoD (UK) set-up, with the CDM subset incorporated therein, is illustrated at Fig. 2 below.

It would be observed here, that the CDM is a four star general/equivalent, same as the Chiefs of Naval/General/Air Staff.

In the Indian context, if adopted – this would essentially mean delegation to the CDM (I) the responsibility and empowerment of the following existing authorities:-

- Master General of Ordnance (MGO) + Quartermaster General (QMG) + E-in-C + Part of Adjutant General (AG).

- Air Officer-in-Charge Maintenance (AOM)

- Chief of Material (COM) + Controller of Warship Production & Acquisition of the Navy.

- Special Secretary / DG.Acquisition – MoD.

- Department of Defence Production (DDP) of MoD.

Though desirable and pragmatic, in the Indian context, this does not appear to be feasible in the near future.

Other Global Players

Functionally, the US, French and the British systems are similar to each other. All of them have created a dedicated logistics cadre. The US and British armies have opted for inducting officers at the junior levels from the QM and MGO’s branches into the logistics branch. But they have been allowed to retain their parent branch status and specialisation – to enable them continuity, promotional prospects, and also to retain their skills and emotional/regimental bonding with their original branch.

Functionally, the US, French and the British systems are similar to each other. All of them have created a dedicated logistics cadre. The US and British armies have opted for inducting officers at the junior levels from the QM and MGO’s branches into the logistics branch. But they have been allowed to retain their parent branch status and specialisation – to enable them continuity, promotional prospects, and also to retain their skills and emotional/regimental bonding with their original branch.

The French and the Germans have an Armament Branch separate from the Combat Arms. The point to note here is, that in all these countries, the promotion prospects in the Combat Arms and the Support Services are comparable.

From the outset, USSR and China have had a dedicated logistic branch to support the military. The erstwhile Soviet military had a dedicated Marshal of Soviet Union as Deputy Minister of Defence, responsible for the logistics of the entire Armed Forces. He was also the coordinating authority at the national level.

Indian military is perhaps the only modern armed forces in the world, which has the distinction of not believing in a joint logistics organisation.

Indian Army

In the case of the Army, the support Services are responsible to provide the requisite logistics to the combat arms. Today, these services come under four different Principle Staff Officers (PSO), to the Chief of Army Staff (COAS).

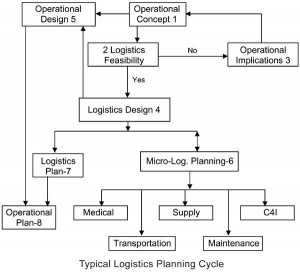

Instances related by retired logisticians indicate serious disconnect between the combat arm leadership and, the logisticians in the field. The crux of the issue, boils down to the absence of a credible institutional mechanism for interactive, operation cum logistics process, specially, at operational and tactical level. A typical flow chart illustrating the process needed to be incorporated is at Fig. 3 below. This realisation has presumably led to the induction of DG Operational Logistics Organisation (DGOL) in the Army HQs. He is currently under Vice Chief of Army Staff (VCOAS)

Presumably, the above arrangement is an interim one–till such time as appropriate reorientation takes place and logistics become fully integrated. Ideally, emulating the British Army model would serve the purpose. This would be the most difficult step to take–bearing in mind the large momentum and the deep historical baggage, requiring a change of direction. 2

Presumably, the above arrangement is an interim one–till such time as appropriate reorientation takes place and logistics become fully integrated. Ideally, emulating the British Army model would serve the purpose. This would be the most difficult step to take–bearing in mind the large momentum and the deep historical baggage, requiring a change of direction. 2

Computorised Inventory Control Project (Cicp)

The Army has now, also taken the next bold step of computerisation of the logistics management. CICP of the Army Ordnance Corps (AOC) was sanctioned in 2001.

Army’s initial attempt was to have a customized system of CICP. Early this year, however, it was decided to change course and proceed with a decentralised solution – adopting a commercially available Enterprise Resource Planning (ERP) route. The system has a modular architecture and can be built up as one goes along. And with experience, the system can be easily upgraded, in line with the technology of the time. The Request for Proposal (RFP) for this is expected to be finalised shortly.

The Army Service Corps (ASC) Stores Monitoring & Control System (ASMACS) operates independently.

Indian Air Force

In the case of the Air Force, single point responsibility for conventional logistics management lies with the Air Officer in Charge Maintenance (AOM) at the Air HQs. The material management and physical distribution function is performed by the Logistics Branch. Maintenance of aircraft and equipment being the responsibility of Air Engineering Branch (Mechanical)/(Electrical). The overall responsibility rests with the AOM.

In an environment of shortages, centralised control is inevitable. It is considered that the advantages of transparency, and allowing on-line data access to lower formations on real time basis, far outweigh the perceived disadvantages.

In Command HQs – logistics and maintenance branches are responsible to the Senior Maintenance Staff Officer (SMSO). The Command Logistics & Maintenance Officer (CLMA) is responsible to the SMSO for all logistics activity of the Wings / Units within the Command.

Integrated Material Management Online System (Immols)

To facilitate logistics activity of IAF – a customised IMMOLS was developed. The facility establishing audit compatibility was inaugurated recently by the Raksha Mantri (RM). Also, the emphasis of the prime user of IMMOLS seems to be more towards central control.

In an environment of shortages, centralised control is inevitable. It is considered that the advantages of transparency, and allowing on-line data access to lower formations on real time basis, far outweigh the perceived disadvantages.

Indian Navy

The US Navy (USN) and the Indian Navy (IN) cadre structure are poles apart. In the USN, the line officer, heads all departments on board a ship. One day he could be an Engineer Officer, and on another, he could be a Navigator/Gunnery/Communications/TAS/Executive/Commanding officer etc. They are, however, highly dependant for the day-to-day running of the Engineering Department onboard to enlisted technical sailors, NCOs/JCOs.

In the case of IN, on the other hand–the departments are headed by specialist officers. On board ships, there are no horizontal movements possible between the Executive and the Engineer officer. The sailors on board are divided into three categories – the highly skilled Artificer/ Mechanician, the semi-skilled Mechanic and the Seaman. This situation is likely to continue even after the intake of sailors is raised to 10+2 level and that of the officers upgraded to B Tech level for the Executive Branch. Improvement can only come about when Engineering and Electrical (E & L) branches are merged, the logistics function is restructured, and user maintainer concept is implemented in letter and spirit. Alternatively, the US Navy’s “line officer” system would need to be adopted, along with their logistics concept.

The Navy was fortunate, for having chosen the model of in-house design, not only because ““ there were no takers in the industry at the time, but also, because, this had the intrinsic advantage of the Navy (as the user), being fully involved and committed in the design choice ““ from the concept stage to delivery and induction into the service.

The Controller of Logistics (COL) is responsible through the Chief of Material (COM), for most of conventional logistic activity for the Navy. Overall the COM is responsible for the material state of all ships, submarines s/m, infrastructure and equipment. Induction of any equipment / technology into the Navy has to have COMs endorsement. He is also the technical authority for all the Dockyards and Base Repair Organisations. Controller of Warship Production & Acquisition (CWP&A) under VCNS is responsible for all warship production in India and acquisition from abroad. 3

In the area of Design, Development and Production – the Navy has had distinct advantages over the other two services. The indigenisation orientation was the hallmark of all the Chief of Naval Staffs (CNSs) since Independence. The ships and submarines being an integrated fighting machine, with multi-disciplinary functions incorporated within–further facilitate this.

The Navy has graduated, in stages from designing and building small ships and sophisticated destroyers to an aircraft carrier and a nuclear powered submarine. To achieve this end, the Navy started training naval designers abroad from the early 1950s. An in-house, multi-disciplinary, Design Bureau was also set up.

The Navy was fortunate, for having chosen the model of in-house design, not only because – there were no takers in the industry at the time, but also, because, this had the intrinsic advantage of the Navy (as the user), being fully involved and committed in the design choice – from the concept stage to delivery and induction into the service. All the stakeholders had full opportunity to have their say, at each stage. Backing out of any project mid-stream was out of the question, since every step was a corporate decision, supported with requisite funding. Any delay in freezing the design or thereafter, requiring changes in equipment/weapon package would naturally result in cost/time over-runs. Today, the order books of all PSU shipyards are full. To make up for their poor productivity, there is an urgent need for adopting modern modular construction methodology and multi-skilled workforce. Also, emerging private sector shipyards need to be encouraged to provide the much needed competition.

Due to lack of such long-term commitments, vision, and frame of mind, the Army and the IAF, are still struggling to induct their first indigenous Main Battle Tank (MBT) and Combat Aircraft into respectively.

Integrated Logistics Online Management System (ILMS)

The Navy has also developed a customised logistics management system. ILMS was formally launched in December 1997. ILMS is also audit compatible. ILMS (Air) deals with naval aviation spares. Weapons Equipment Depots (WED) and Armament Stores Depots (ASD) work outside the ILMOS system.

Standardisation & Codification

Standardisation and codification is the key to efficient and effective logistic management. Almost from the outset, the Soviet Union had, to a great extent, universalised their standardisation process. Even in late 1960s, one could find the same prime mover, being used in different warships and ashore for power generation, and same being employed for driving heavy duty specialised commercial/military vehicles and common tractors for plowing the fields. Also, HP air compressors, common motors, pumps and communication equipment were used across the board, for multifarious end use.

As far as the integration of Military Logistics is concerned ““ intra-service integration, to a large extent, already exists in the cases of IN and IAF. Also, Army Medical Corp (AMC), Military Postal Service, Movement Control Organisation, Military Engineering Service (MES), Canteen Service and to a limited extent even the ASC are already part of a unified service

The Directorate of Standardisation (DoS) was established within the MoD about 46 years ago. Codification is part of their charter. For which purpose, they adopted the NATO Codification System (NCS) format. Today they have a strength of about 300 personnel.

All of Europe including Russia, erstwhile Warsaw Pact Countries, USA, Canada, Australia, Scandinavia, and most of South America use the new NCS format for codification. In June 2008, India has also become a Tier I member.

The June 9, 2008 MOU with Allied Countries (AC) 135, in Brazil, has the potential of revolutionising the Indian scenario. At least as far as codification is concerned, the operationalisation of Tier I agreement with NCS has the possibility of bringing all the three services and DoS on to the same grid. This would also make it possible to remove all the technical hurdles in the way of sharing data between ILMS/IMMOL/CICP/ASMACS/ILMS (AIR) etc. However, to convert this into reality, a change in mind-set change would be essential.

Experience of the western world, in adopting an integrated and computerised logistics system has confirmed following advantages:-

- Efficient & effective logistics system.

- Higher customer satisfaction.

- Prompt response to flexible operational demands

- Large reduction in stock holdings.

- 15 per cent savings in inventory costs.

- Better sourcing contracting – leading to further 20 per cent savings.

Defence Capital Acquisition

Looking at it holistically, capital acquisition forms an important part of the overall logistics activities. Defence Procurement Procedure (DPP) documents are a series of documents promulgated by MoD, since 2002. These form a near comprehensive set of documents, covering all feasible options available in defence procurement process, along with the detailed procedures involved.4

In the DPP 2006, there are some ambiguities in the new “make” subgroup, promulgated under the broad design and development category. And the “offset” options introduced need further elaboration. The proposed five-year plan for Capital Expenditure on defence is estimated to be of the order of $100bn. This would give an opportunity of extracting transfer of know-how and cutting edge technology benefits, worth at least $21bn. This must be judiciously exploited. Presumably, these would have been taken care in the next version of the document (DPP-2008), released by the Raksha Mantri recently.

The Army to establish an integrated intra-service logistics system/organisation from Corporate/Command HQs & Central Depots to field units.

Naval involvement with shipbuilding, as brought out earlier, has been so extensive that a dedicated chapter had to be devoted, in DPP-2006, to this exclusive category. The naval model has reached such a mature stage that this model could be dovetailed into a DSES (UK) model discussed earlier.

The capital acquisition process has been divided into categories. For illustration purposes – a set of typical examples has been shown at Fig. 4.

Proposed Immediate/Short Term Action Plan

- Appoint a CDS. 5&6

- An affirmative JCSC decision on the long-term need for a unified military logistics system.

- A Joint Logistics Committee to evolve and adopt an integrated codification doctrine – within a quarter.

- Garner all wherewithal available in the country, towards rationalisation of military codification system.

- Get full mileage out of following opportunities knocking at the door: –

- Tier I membership of NSC – June 9, 2008.

- Indian membership of ISO.

- Utilize all US FMS transactions – to gain full access to NSN catalogues and their supply chains.

- Russian Federation Protocol offering supply of spare parts catalogue with NSC based part numbers.

- Assistance from local ERP vendors – to integrate logistic soft ware.

- DoS to add above to their charter and give priority assistance.

- The Navy needs to take its logistics restructuring process forward and overhaul the cadre structure to give it technical orientation and make it totally inclusive.

- Rationalisation of the command structure, as applicable to logistics on the model of the IAF, would also be necessary.

- Carry forward the DGOL prescription to its logical conclusion, in line with Brigadier Sarin’s suggestions.2

- The IAF to inter-link the IMMOL’s online real time connectivity with field units and other defence aviation establishments. Command & Control will continue to remain with AOM.

- The Air Force to become more institutionally involved and committed to military aeronautical design and development projects. Utilise the openings becoming available in projects such as Fifth Generation Fighter Aircraft (FGFA) etc.

- CICP is, in any case, all set to relaunch itself. In the circumstances, they would be expected to adopt the new NCS norms.

- In due course, the Navy & IAF, to also follow suit–the earlier the better.

- Adopt modern, ware-housing technology and supply-chain management system. Provisioning of improved mobility, mechanical handling facilities and universal use of bar-coding system etc. would go a long way in achieving higher efficiency and productivity.

- CIDS to use Andaman & Nicobar Command to develop, on priority, a pilot project to implement an exclusive unified command logistic system.

- To ensure speedy and phased execution, JCSC must immediately appoint a dedicated Dy CIDS (Logistics), if required from own resources, to steer through this important programme. Also, institute a system of quarterly SITREP from CIDS to the JCSC.

- Navy to undertake commensurate cadre structure review, and implement E&L merger of Branches and introduce User Maintainer Concept on board ships.3

Medium & Long-Term Perspective Plan

- The Army to establish an integrated intra-service logistics system/organisation from Corporate/Command HQs & Central Depots to field units.

- Implement the “out of the box option” presented for HDM.6

- Progressively, the three services to restructure infrastructure in line with the British model.

- Extend above programme to Theatre Commands as they evolve.6

- Evolve a unified/integrated logistics management structure for the three services.

- Progressively evolve a structure akin to UK’s DSES to take on the total logistics responsibilities.

In conclusion, it may be added that:-

- As far as the integration of Military Logistics is concerned – intra-service integration, to a large extent, already exists in the cases of IN and IAF. Also, Army Medical Corp (AMC), Military Postal Service, Movement Control Organisation, Military Engineering Service (MES), Canteen Service and to a limited extent even the ASC are already part of a unified service.

- The immediate and short term action plan proposed above is considered to be well within the scope of the uniformed fraternity. Only joint will and perseverance is needed.

- The urgency is such that the above need not wait, either for the appointment of the CDS or the JCSC, to arrive at a decision on adopting a unified military logistics system

- If one can come to an amicable agreement within the JCSC on such contentious an issue as the Unified/ Joint Space Command Concept, then, such mundane issues as above, could also be resolved by mutual discussions.

Notes

- Extract of Para 2(a) to NSC Directive No. C-180/1/2000 – NSCS (CS), May 17, 2000. “Since accountability to Parliament constitutes the basic feature of Government of India, the task force, while making recommendations, will examine the evolution and changes in this respect that have taken place in other parliamentary democracies. In particular, the UK model should be studied closely.”

- Brig.Parmodh Sarin, Military Logistics–the third dimension, (New Delhi: Manas Publication).

- AP Revi, “Naval Acquisition Matrix,” Indian Defence Review, Vol. 21(4), p. 82.

- Defence Procurement Procedure Version–2002/06.

- AP Revi, “Higher Defence Management” Indian Defence Review, Vol. 21(2), p. 91.

- AP Revi, “Out of box option for HDM,” Journal of Indian Ocean Studies, Vol.14 No.3, p. 418.

dear sir/mam,

how can i get job in indian army logistics department.

please do help

Hi sir, may i have the permission to use your material for my project? My topic too is integrated material management across the services.