8. Lessons & Major Policy Issues

As the foregoing would show Offsets have helped in sub contractorisation of low end products and services, setting up simulator and training facilities, project management, depot maintenance facility, GHE/GSE.

However, in terms of Foreign Direct Investment in production and R&D, JV arrangement and exports the response so far has been rather tepid from the foreign OEMs.

Some of the major policy issues that need to be addressed urgently in order to realize potential of offsets are increasing FDI cap in Defence & including technology transfer as a policy option.

FDI Cap in Defence

The DIPP (Department of Industrial Policy & Promotion) circulated an approach paper rooting for more than 74% FDI Cap in Defence production to offer significant incentives to foreign companies for transferring leading technology.46 While CII, FICCI are generally guarded while recommending increase to 49%, foreign OEMs recommend 50% FDI for manufacturing & 100% for services sector. Dr. Kelkar & Deepak Parekh recommend FDI higher than 49% if they bring in critical technology.47 Air Commodore Jasjit Singh supports the case for increasing FDI to 49%.48

Countries like China witnessed substantial increase in FDI inflow i.e from $5.8B (1990) to $67.3B in 2007 because of liberal FDI norms. The inflow was predominantly to the manufacturing sector (51%) boosting China’s export singnificantly.49

Dr. Arvind Virmani argued before the FDI group (2000-2004) in Planning Commission that 100% FDI in high technology defence equipment is preferable to being perpetually dependent on imports for the same items. 50

SA to RM is of the view that FDI increase may improve manufacturing capability but not design capability.51

JV arrangement with Russia for Brahmos cruise missiles is considered as a useful model. Brahmos model with 50 : 50 FDI participation using core competence of India & Russia is perceived as a successful model for future needs of the nation.52 The Brahmos JV was formed with Russia in 1998 with 50:50 equity participation ($300 m). Today it has successfully delivered its product, has an order book of $4B which is to swell to $12B soon. It has been made possible due to the commitment of both JV partners & commitment of services.53

India has come to be recognised as an economic and technological powerhouse in the making. Manufacturing now accounts for above 27% of India’s GDP, contributes 53% of total exports, 79% of FDI & employs 11% of the

Workforce.54 Sectors like Telecom with a FDI limit of 74% has been receiving significant FDI inflow (around $ 25B)55 in the recent past despite the global financial crisis.

Therefore, there is a strong case for increasing FDI to atleast 50%, so that the JV arrangements make economic sense to the OEMs in terms of Return on Investment.56 Dr. Vivek Lall, VP, Boeing India is also of the view that increasing FDI cap to 49% will be consistent with other sectors & foster long-term investment.57

Technology Transfer

Inclusion of technology transfer for identified key technologies seems to be gaining vide support in offset policy.

Many DPSUs like HAL,BEL, BDL, MDL, Midhani have been recipients of Technology predominantly from Russia and a few Western sources.

While substantial indigenisation has been achieved in non critical technologies but in critical technologies, OEMs rarely provide manufacturing know how leading to continued dependence on OEMs for upgrades.58

Prof. Brauer, is also of the view that just because India is a big buyer of defence equipment does not guarantee that counterpart countries will transfer relevant technology.59 Even if transferred, it can become obsolete by the time it is installed and absorbed.

Dr. Kalam, feels that TOT in the past to DPSUs/OFs only provided some manufacturing capabilities but not key technologies.60Adm Suresh Mehta, Ex-CNS is of the view that TOT should be a stepping stone to leapfrog and develop indigenous manufacturing technology than when transferred. Successful technology needs defined underlay & buyers must have capacity or knowledge base to absorb superior knowledge smoothly. Know why must be insisted & no restrictive conditions accepted.61 Mr. Mohanty, Ex-CMD, HAL is, of the view that HAL succeeded in getting high end technologies because of dealing with foreign suppliers with firmness.62

For instance, Key technologies like Single Crystal blade for turbines was passed on by Russia and successfully absorbed making Engine Factory,

Koraput an important destination for getting engine components machined by reputed engine houses like Pratt & Whitney.63

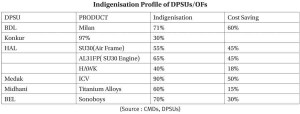

A profile of indigenisation achieved in of various products through technology concomitant transfer and cost reduction worth import cost of DPSUs/OFs is placed below:

It would thus be seen import dependence has been substantially whittled down with cost economies because of substantive technology absorption in manufacturing by our DPSUs & OFs.

Some economists suggest that obtaining technology through offsets is a more efficient way than direct purchase,64 while DGIDSA feels that buying TOT is a better option65 as it will be on a competitive basis. There is also a view that when TOT is part of a large contract, the risk is shifted to the vendor who will have greater incentive to transfer technology successfully.66 Dr. Vivek Lall, VP. Boeing opines that the ‘Buy & Make’ policy is adequate for platform related technologies. However, technology based offset projects share IPR (Intellectual Property Rights) and are designed to assist, industry, R&D institutions and universities.67

Dual Use Technology

Impact on the civil aviation sector consequent on inclusion of this sector in DPP-2011 is too early to judge. However, indications are, it has generated enthusiasm particularly for security related products,68 aero structures and cabins.

Japan has been the prime beneficiary of dual use technology in areas like electronics, cryptology, sensors etc.