The final choice of platform under project 75(I) should, therefore, be based not only on the quality of the submarine, but also on the extent of TOT and certain other factors which would be given appropriate weightage and be matrixed with the cost to determine the final strategic partner and OEM combine. Identifying these factors and assigning them inter se weightage is an involved process. While some of these factors can be culled out of the RFI/RFP, there are others factors that would be governed by our past experience, a pragmatic analysis of operational imperatives and the external environment.

Australia initiated plans to replace the Collins class submarines, with a study titled ‘Future Submarine Programme’ or SEA 1000 somewhere in 2009, though the preliminary work had started in 2007. They inked the $40-billion contract with DCNS for twelve Shortfin Barracuda submarines in early 2017, and the first submarine is now likely to sail in 2030. Similarly in India, while the concept of a second submarine production line was articulated in the CCS paper in 1999, the first concrete step was taken only in 2010, when a two-page RFI for Project 75(I) was promulgated. This initiative turned out to be stillborn and the project was re-activated in May 2017, with the promulgation of the Strategic Partnership (SP) framework, as part of DPP 2016. This was followed by the promulgation of a detailed RFI to foreign OEMs, in mid-July 2017.

Notwithstanding our poor track record of procedural and decision-making delays, it may be realistic to expect the signing of contract for P 75(I) in end 2019/early 2020 and cutting of steel by early 2022. The induction and deployment of the first of these submarine would probably be around 2032. Further, both nations are determined that the current programme must not only deliver state-of-the-art submarines, but, more importantly, establish an indigenous eco-system which would ensure that the next class of submarines are designed and built in the country. Thus, the timelines as well as the intended deliverables of our Project 75(I) and the Australian SEA 1000 programme are ‘comparable’; at least for the purposes of the ‘broad analysis’.

While it is only natural that we analyse the factors that may have influenced Australia’s choice of the Shortfin Barracuda, we must also undertake a parallel analysis to evaluate who our likely three top contenders are, and what ought to be the criteria which should impact our final selection.

Why Australia Chose the French Shortfin Barracuda

The Royal Australian Navy (RAN) needed a multi-role, long endurance, long range submarine capable of taking part in joint operations with allies. This submarine was to replace the existing Collins Class, which are among the largest diesel electric submarines in the world. This translated to an above 3,000-tonne submarine. Accordingly, the Australian government shortlisted three contenders – the German Type 216, the Japanese Soryu Class and the French Shortfin Barracuda, an evolved version of the SSN. The Kilo, Scorpene, Type 214, Swedish A26 were eliminated.

A major aspect of submarine design is that if the hull form for a 30-knot platform is designed, other issues such as stealth, control surface optimisation and hydrodynamics are intrinsically taken care of. Thereafter, even if such a high speed platform is initially designed for lower speeds, subsequent technological upgrades are not only viable, but also extremely cost effective. Thus such a platform design caters for subsequent upgrades, as the Transfer of Technology (TOT) assimilation and the indigenous industry mature with time. This probably impacted the final Australian decision more than other criteria.

Type 216 Submarines

The Type 216 offered by Germany was an enlarged (4,000 tonne) Type 214. It met all operational and technical requirements of the RAN. Australia chose DCNS over tKMS, despite the fact that the German offer was nearly half of the $40 billion quoted by the French. Design of submarines requires a pre-sizing capability of the yard. For example, the basic speed and endurance requirements drive the electrical and engine power requirements of the submarine, which themselves impact the volume and compartments of the submarine. Further, in large submarines, all the equipment needs to be oversized and this impacts everything – larger power requirement, larger sea water systems and more space and weight. Therefore, this pre-sizing capability of the designer was considered essential. The designer’s pre-sizing capability is based on both, experience well as empirical knowledge. However, empirical laws or design rules are not linear. Thus the Australians felt that tKMS which has experience of building only 2,000-tonne submarines cannot necessarily rely on their experience and knowledge when designing the 4,000-tonne Type 216.

Soryu Class Submarines

Notwithstanding the tonnage of the Soryu class, its performance is quite similar to a ‘medium modern SSK’, similar to a Kilo or Type 214. Within a few days of departing from their port, Japanese submarines are on patrol in North Korean and Chinese waters. Thus, while, their 6,000nm range of operations meet the unique needs of the Japanese Maritime Self Defence Force (JMSDF), they do not meet the needs of the Australians or any other navy aspiring to operate ocean going submarines.

To meet the Australian need of long range and endurance, the Soryu was to be modified with a new AIP system and new Lithium–Ion batteries, among other things. Further, the length would need to be increased by six to eight metres to meet the requirement of additional fuel and enhanced habitability due to distant and longer deployments. The fitment of Lithium-Ion batteries also entailed completely new electrical architecture, ventilation system as well as new engines to optimise the use of these batteries. The end result would again be a new design due to the major modifications required.

Another major factor was the build technologies required in the Soryu that has an operating depth of 900 metres. The metallurgy and welding technology required for such a pressure hull and other sea-water systems would be unique, state-of-the-art and extremely demanding. Whether the industrial ecosystem of Australia or for that matter any other nation, attempting to establish such an ecosystem indigenously, can absorb such complex technology or not, is a moot point. Finally, Japan’s lack of experience in TOT management and industrial cooperation in the sphere of complex defence programmes, may have also influenced the Australian decision.

The Shortfin Barracuda

DCNS proposed an ‘evolution’ of their Barracuda-class SSN into a conventional submarine, fully compliant with needs of an ‘ocean going’ Navy. This implied that its hull form, control surfaces hydrodynamic, stealth techniques, machinery and platform systems – all were designed for speeds of above 30 knots. The Shortfin Barracuda exceeded the capabilities of its competitors in terms of speed, endurance and weapons. Its designed transit speed is at least 40 per cent higher than others. This alone is significant as it can deploy faster, further and remain on patrol for a longer duration. Also, DCNS comes with the extensive experience of designing and building large submarines and is used to complex defence programmes involving local partners and indigenous ecosystem.

Finally, while the current political and security environment of Australia may not demand a nuclear-capable navy, if the trajectory of the regional geo-political calculus is any indication, such a need in the future, cannot be ruled out. Under such a scenario, the only submarine which can be scaled up to a nuclear SSN is the Shortfin Barracuda. Thus, the choice of the Shortfin Barracuda over its contenders may have also been influenced by this strategic need. No other factor seems to justify their decision to pay $41 billion for 12 boats to DCNS for the Shortfin Barracuda as against the $20-billion price tag for the same number of Type 216 offered by tKMS.

Likely Contenders and Crucial Criteria For Evaluation – Project 75 (India)

Based on the aforesaid analysis, it may be prudent to assess the likely ‘top three contenders’ for India’s Project 75(I) and list the ‘criteria of significance’ which should and are likely to form part of the evaluation process. This is being attempted despite the inadequate and unconfirmed information currently available in the open domain.

Likely Contenders

It is understood that the RFI for Project 75(I) is addressed to six foreign OEMs. As mentioned earlier, no existing submarine type (Type 214, Scorpene, Kilo) meets the requirements of P-75(I). The Spanish S80 and Swedish A26 are extremely unlikely to be in the top three for reasons similar to the Australian programme – their under-development submarines are unlikely to meet our QRs and their ability to design ocean-going submarines of above 3,000-tonne is unproven/suspect.

While the Soryu was a serious contender for the Australian programme, it is unlikely to be in the top three for Project 75(I). The reasons are similar to ones which prompted the Australians to reject the Soryu for their SEA1000 programme. In addition, there are serious apprehensions whether the Japanese would be willing to transfer design and build technologies as envisaged in the RFI and can the advanced engineering and metallurgical technologies used in this class, be absorbed by our yards and be supported thereafter by the existing indigenous industrial ecosystem?

The Russian design, on the other hand, though not considered by Australia, is certain to be a contender for the Indian programme. Our experience of operating Russian submarines dates back to over 50 years and they have been strategic partners for the indigenous ATV program.

The French DCNS and German tKMS continue to remain the top contenders for the Indian project 75(I); as was the case in the Australian programme. Thus the top three contenders for Project 75(I), in no order of preference, would be the Russian ‘Modified Amur’, the French ‘Shortfin Barracuda’ and the German ‘Type 216’ classes. As on date, none of these submarines exist and would require to be designed and built to meet our specific requirements.

Evaluation of Options for Project 75(India) – ‘Criterion of Significance’

The RFI promulgated is detailed and comprehensive. Its tone and tenor does give a fair idea of what can be expected in the subsequent RFP and the final evaluation process. Based on the currently available inputs and our appreciation of the external environment, an attempt is being made to identify ten likely ‘criterion of significance’ for evaluating the contenders. The fact, that selection of criteria and their weightage is a dynamic process, is well understood.

Project Cost

The acquisition cost of the Shortfin Barracuda to the RAN is quoted to be $4.3 billion per boat. This is more than twice the tKMS offer to build 12 boats of Type 216 at Adelaide at $1.66 billion per boat. As per open literature, the cost of the nuclear Barracuda to the French government is $2.3 billion, the cost of the Virginia class is $3.6 billion and a Soryu-class built in Japan is $0.75 billion. The international price of a modern SSK is about a billion. The projected acquisition cost of six SSKs under Project 75(I) is about Rs 60,000 crore, which translates to about $1.0 billion per boat. Even if these figures are indicative, the moot questions is firstly, can the French now quote a substantially lower cost of the Shortfin Barracuda for our programme and secondly, notwithstanding certain superior tech parameters with additional weightage, can the Indian decision maker, ignore a substantially lower L1, in favour of a much higher quote?

Fuel Cell AIP System

The only fully developed and sea-proven fuel cell system is the German system (PEMFC + metallic Hydrides for H2 Storage). Since the metal Hydride-based Hydrogen storage solution was found to be unsuitable for 2,000-tonne plus displacement, Germany chose to go in for methanol reformer-based FC system, in conjunction with the improved PEM fuel cells. Prior to deciding on this approach, in 2007, the German federal government funded tKMS to conduct a methanol vs diesel reformer study. The study results were instructive. The hydrogen to carbon ratio of diesel is only 2:1 as against 4:1 of methanol. The diesel reformers run at 8500 C, which translates to higher heat inefficiencies (which, in a submarine, translates to enhanced thermal signatures, higher air-conditioning capacities and hotel loads) and longer start-up times, when compared to methanol. Finally, since the diesel carried by submarines is not sulphur free, the output at the reformer requires a sulphur purifier, which is as big as the reformer itself. The German reformer-based second generation Air Independent Propulsion (AIP) system for the 4,000-tonne Type 216 is undergoing set-to-work at Kiel and is designed to provide the Type 216 with an AIP endurance of 30 days.

The French and Russian systems are under development and are unlikely to be operationalised before 2025. The Lada programme of the Russian Navy (the export version being the Amur 1650) has been discontinued after the first boat, for various reasons, including the non-availability of an AIP. Even the Australian French Short fin Barracuda is without an AIP system. The indigenous fuel cell system under development by NMRL uses a Sodium boro-hydride H2 generators and Phosphoric acid fuel cells. This technology has been used on land-based applications since 2010, but has not been put on a maritime platform anywhere in the world due to serious safety concerns. Its application in the closed, hazardous and hostile environment of a submarine in the perceivable future is highly unlikely. Thus, the only proven fuel cell AIP available is the German system. They should also be our first choice to help us in our indigenisation effort.

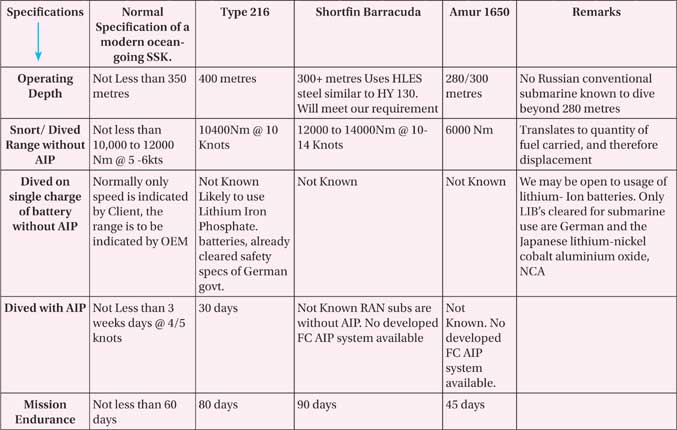

Operating Depth, Range and Endurance

The entire design and machinery/equipment fit of the platform flows from these three specifications. Known details as per open literature are tabulated below. Since the Amur 1650 does not meet any of these requirements, Russia may offer yet another ‘on paper’ version of the Amur. On paper, there exists up to six versions, starting from the 450-tonne to 1,850-tonne. The point of concern is that there is no Amur submarine built to date. The only Lada class built was rejected by the Russian Navy and the Amur was to be the export version of this rejected Lada.

Weapons

The weapons suite of P-75(I) will be nominated by the Indian Navy and is likely to consist of the tube-launched ASCM, LACM, a HWT and mining capability from both, the torpedo tubes and an external detachable mine chute. The only class to have a proven external mine saddle is the German design. As the choice/availability of weapons is beyond the scope of the OEM, the only concern is their integration capability/willingness. Towards this, the following merit consideration:

• The responsibility to obtain necessary clearances and interface data from the weapon designer will reside with Indian Navy and not the submarine OEM.

• The responsibility to obtain necessary clearances and interface data from the weapon designer will reside with Indian Navy and not the submarine OEM.

• tKMS has already indicated willingness and displayed capability to integrate any weapon as long as interface data is made available to them by the client. The Harpoon is already part of the Indian Navy inventory being integrated with the Shishumar class. They have, in the past, indicated willingness and ability to integrate the Tomahawk, Klub or the BrahMos missiles if interface details are made available.

• DCNS have been extremely reluctant to interface non-French/competitors weapon systems into their design. Case in point is the integration issues of German HWT in the Project 75. This has led to a situation that the Kalveri Class submarines will be commissioned without a HWT of our choice. To avoid such a situation again, their willingness and cost of integration should be established and factored into the final cost. Expecting the weapon suppliers to bear this integration cost, on a NCNC basis even before the weapon is selected, reflects poorly on our programme and contract management. For Project 75(I), the Russian Klub and BrahMos are not comparable in terms of range or performance of the Tomahawk. Further, the indigenous BrahMos does not have a tube-launched version yet. However, DCNS can provide us with the 900km SCALP Tube-launched LACM, albeit at a steep strategic and commercial cost. The only other source of a similar weapon would be a Government-to-Government arrangement for the Tomahawk from the US.

• Western weapon manufacturers may be reluctant to share interface data for fitment in a Russian design submarine. Fitment of either Russian or indigenous weapon package may, therefore, be a fait accompli, in case we decide to go in for a Russian design for project 75(I).

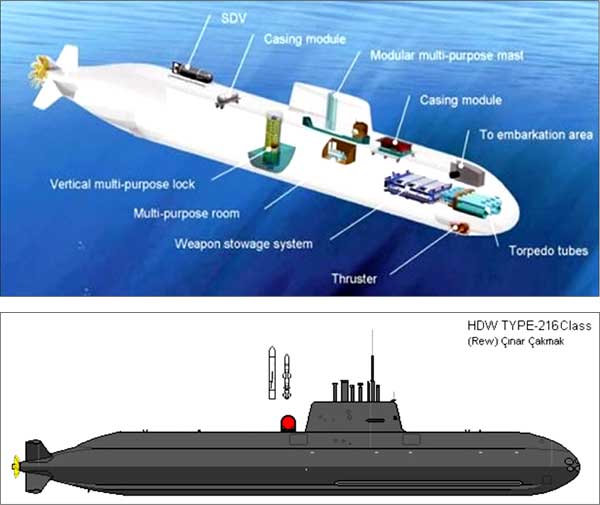

The Flexi payload concept of Type 216

The RFL mention iSTAR, mining, training and Special Forces operations as secondary roles for the submarine. The design also needs to support operations ashore in a networked environment. The Amur design does not have any known additional characteristics to cater for such requirements except the regular ESM mast and mine carrying capacity in lieu of torpedoes/missiles. The Shortfin Barracuda addresses some of these requirements by the provision of UUVs, UAVs and an ‘on hull dry dock shelter’ for divers and their delivery vehicles. The Type 216, on the other hand, complies with all these requirements by an external mine saddle and their extremely innovative and elaborates ‘Flexi Payload Concept’ with the following arrangements for mission – based modular payloads.

• Vertical multipurpose locks (3mX2.5m diameter) for Missiles, Mines, Divers Lock, AUVs and fuel oil.

• A multi Purpose Room for fitment of additional iSTAR equipment, sonar consoles, accommodation, laboratory, training and sick bay.

• Casing Payout Modules to carry countermeasures, UUV and divers propulsion vehicles.

• Modular Multi Purpose Mast for payloads such as UAV control, additional communication equipment, ESM, even to fit a gun or short range SAM.

• Weapon Stowage for additional weapons, spare bunks and general purpose stowage space.

OEM’s Current Industrial Footprint in India

Among the three OEMs, the German industrial complex already has a significant footprint in India. Industrial giants such as Siemens, MTU, MAN, ThyssenKrupp and Schneider already have a mature manufacturing and R&D ecosystem in India. This would contribute immensely towards fulfilling the mandate of comprehensive TOT, increasing indigenous content and establishing an ecosystem for local vendor base. The current footprint of the French industry in India is still nascent and in case of Russia, it is almost non- existent.

Experience in Overseas Ship Building, Attitudes towards TOT

Germany has built over 160 submarines and delivered to 20 nations. They have a proven ability to customise, based on the philosophy – ‘as small as possible and as big as necessary’. They have displayed a propensity to share submarine building technologies and capabilities with clients. South Korea has moved from the Type 209 to Type 212 and now to indigenous design Type KSS III. Turkey is building the Type 214 indigenously, with only the material package from HDW. Russia has never built any of its submarines overseas and the record of TOT is non-existent. The French are somewhere in between. While they have built submarines in a few foreign yards, their record of TOT is not as positive as that of the Germans.

Past Experience and Comfort Level of the Navy, Shipyard and MoD

The Indian Navy, yards and MoD have experience of all three OEMs. The SSK contract with HDW is considered as one of the best defence contracts, if not the best. Their operational availability, maintainability and material state even in the 30th year of commission, has been exceptional. They have been periodically modernised to retain operational superiority at MDL itself. The submarines are now being considered for their second mid-life up-gradation which would extend their life by another 12 to 15 years. The Russian Kilo class continue to be sent to Russia for refits and modernisations. Documentation received from the OEMs has been rudimentary, TOT non-existent and indigenous content minuscule. While it may be premature to pass judgement on the operational capability and maintainability of the Scorpene submarines, the project time and cost over runs have been substantial. The indigenous content and level of ToT have also been far from satisfactory. As per sources, there is no clear break-up of costs and the price escalation continues to be open ended. These issues have been raised time and again in the innumerable CAG observations, PACs, PILs and Parliamentary questions.

Conclusion

Acquisition of submarines under Project 75 (I) is the first segment to be governed by the recently promulgated Strategic Partnership framework. The focus of the RFP is likely to be TOT and indigenous content. The end state envisaged is that not only should the Navy get an extremely capable weapon platform, but the nation must acquire sufficient expertise to be able to design, build and support the next class of submarine indigenously. The Australian SEA 1000 programme was also driven by a similar aim. Their decision to acquire the Shortfin Barracuda as the replacement for their Collins Class, therefore, merits close scrutiny.

The final choice of platform under project 75(I) should, therefore, be based not only on the quality of the submarine but also on the extent of TOT and certain other factors which would be given appropriate weightage and be matrixed with the cost to determine the final strategic partner and OEM combine. Identifying these factors and assigning them inter se weightage is an involved process. While some of these factors can be culled out of the RFI/RFP, there are others factors that would be governed by our past experience, a pragmatic analysis of operational imperatives and the external environment.

So when the time comes to take the final decision for the Project 75(I), it is assumed that our collective wisdom of fifty years of submarining and previous pitfalls in the acquisition process will drive us towards a prudent, professional and nationalistic decision. But then, as a local saying goes, you can only wake up a sleeping person; one pretending to be asleep cannot be woken up. Hopefully, it will not be the case this time around!!

I was very impressed wih this article by a former senior Naval Officer until I saw that he is heading the Submarine division of Reliance Defence. Reliance defence most probably has/is partnering with ThyssenKrupp Germany for pitching Type 214/216 Submarine for the 75I program.

Even otherwise, the Germans are reliable suppliers and less susceptible to pressures. The price of course is a major factor.