Keeping an army’s equipment in a combat-ready condition requires considerable personnel and financial resources. Roughly 8.5 percent of personnel in an Armoured Division and a shade less in other formations, work relentlessly to keep combat systems in a high state of readiness. However, with increased focus on counter insurgency operations in the last three decades and restricted deployment of equipment during exercises, there has been a discernible dilution in the focus on operational availability of systems. While garage availability may be extremely high, it does not reflect battle endurance or equipment capability of these systems.

Operational Availability

This term is grossly misunderstood by many and is taken to be the total number of items of equipment available in a unit at any given time. A lot of hue and cry is raised when the number of personnel in low medical category in any battalion or regiment shoots up, so much so that the Army Act gets amended. However, one does not find any such ballyhoo when a number of weapon systems in a unit become non-mission capable. This is because the Army is yet to evolve a suitable metric for Equipment Capability akin to the SHAPE criteria.

Equipment capability is defined as the enduring ability of the weapon system to generate the desired operational outcome or effect and is relative to the threat, physical environment and capability of the maintainer. The vast array of weapons and equipment in the inventory of any force represents a major component of military capability which has to be kept mission-capable 24×7, 360 degrees. Sadly, this vital point is missed out by the planners in the never-ending quest for new systems while doing lip service to the issue of through life readiness of in-service systems, ensured by timely technology refresh initiatives. Consequently, force hollowness spirals, shooting up non-mission capable rates. Modern armies put a premium on Equipment Sustainability, so much so that Sustainability has become a key performance parameter while framing system operational requirements, while Reliability has been added as a Key System Attribute (KSA). A readiness rate of 75 to 85 percent is the norm.

Maintainer Capability

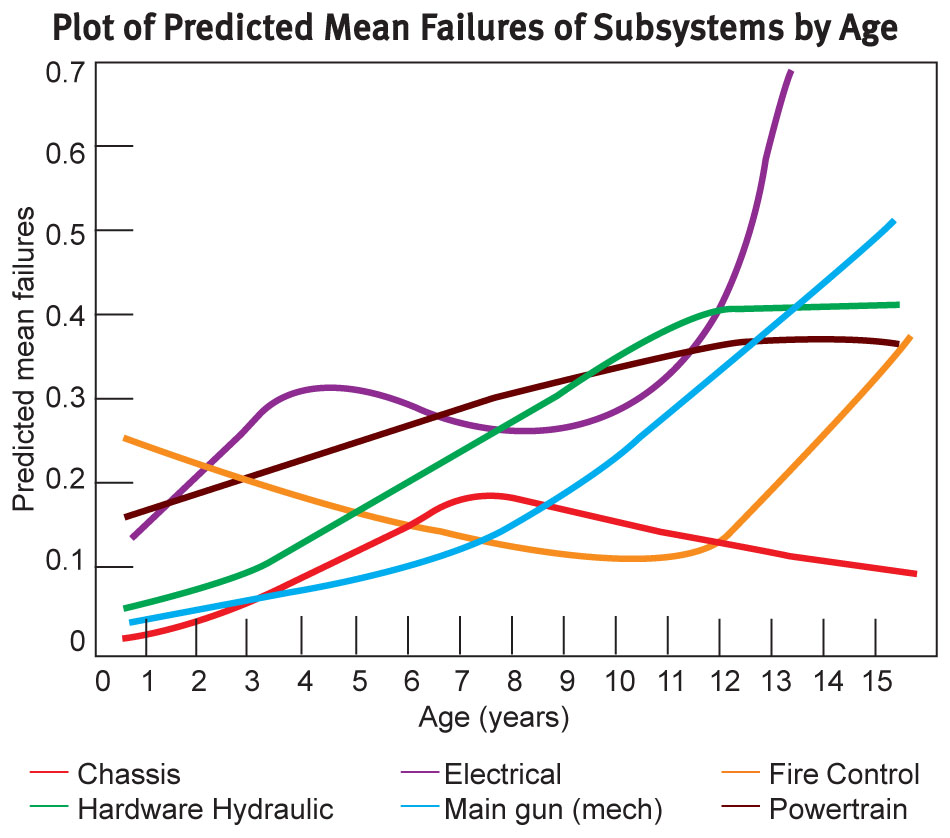

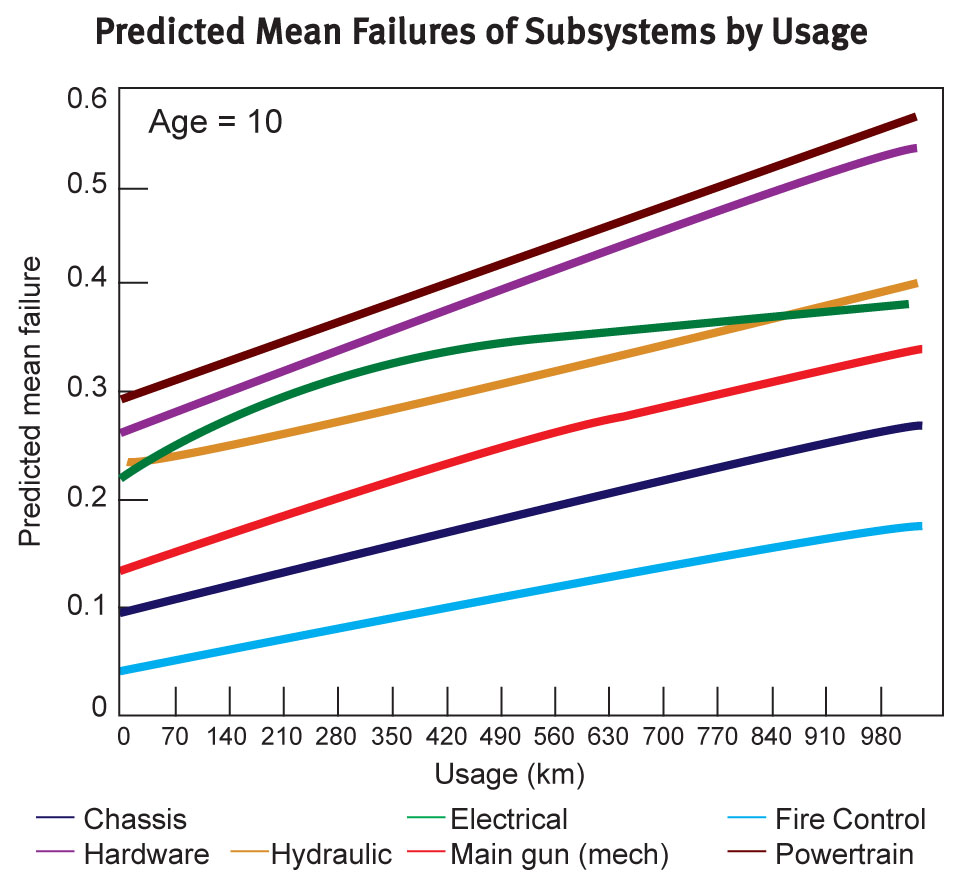

Let us move on to the raison d’etre for an Army investing in maintainer capability. It is an established fact that equipment capability degrades with age, usage and deployment, also called AUD effects. It is for this reason most armies place a great focus on warehousing and preservation of weapon systems. The deterioration is more in electronics, electrical and hydraulics. Studies have concluded that modern day complex systems lose capability at the rate of two to four percent annually, implying that in about ten years, equipment capability will be down to 50 to 60 percent. The graphs below reinforce this assessment.

Except for mechanical systems, most systems show increased failures with age and usage. For example, while the M777 light howitzer may be having an ability to deliver ten to twelve second lines without a mission failure today, ten years later this capability will get severely degraded due to its age, deployment in various terrains and usage. Add to this, the quality of user level maintenance, input materials used, technical maintenance carried out in the open with accompanying dust and humidity, the quality of ammunition and spare parts used, and the extent of degradation in our systems spikes much above global estimates.

It is through a well-established engineering (maintenance and refit) infrastructure that resuscitation of these systems can be carried out to restore their battle endurance and sortie reliability i.e. enabling a gun to fire the same numbers of second lines as it did while entering service; enabling a missile to complete its flight without a malfunction; a helicopter to complete a mission without breaking down; a tank to assault an enemy position without experiencing a critical operating failure. After all, the Army has instituted various measures to keep its soldiery young and physically fit. Similar measures have to be put in place to keep the systems young like new and battle-worthy. A cue can be taken from the modern maintenance infrastructure which the Indian Air Force and the Indian Navy have established for system effectiveness. Without technical support, most war fighting systems will be akin to scrap or dead hardware.

Reliability and Maintainability

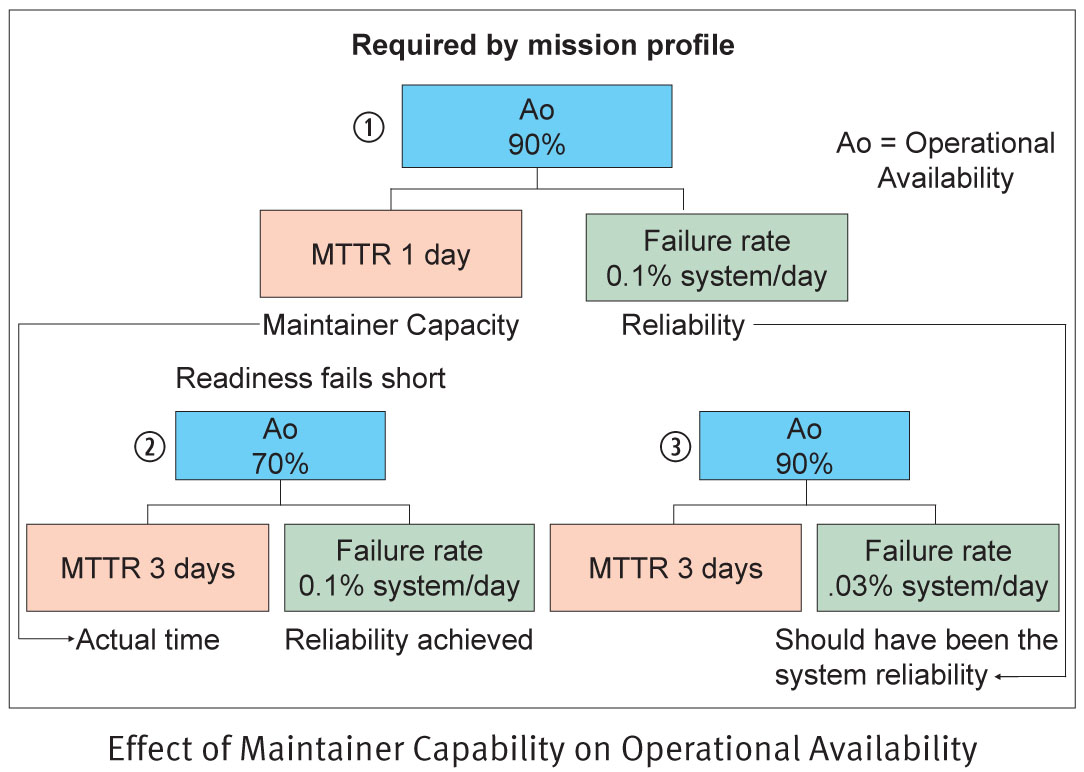

The misleading experiences of exercises, where only one-third of the equipment participates with 100 percent engineering support, and without any combat damage assessment, has for too long, conveyed an “all-is-good” feeling. During Operation Desert Storm, in the 100-hour ground war, the Americans ended up with 20 destroyed Bradley ICVs and another 12 damaged against a subpar opposition. Figure 3 below gives out a relationship between the Mean Time To Repair (MTTR) and operational availability of an artillery regiment in combat, failure could be due to enemy action or mechanical faults.

It is evident how high reliability (probability of survival) and maintainer capacity can sustain high force ratios. If maintainer capacity (broke-to-fix time or MTTR) is three days instead of one, the operational availability of guns in the regiment falls to 70 percent. If maintainer capacity is not improved to one day, the gun should have very high reliability i.e. 03 failures/gun/day to retain an operational availability of 90 percent i.e. 16 guns booming at any point of time. Equipment reliability and maintainability assume critical importance as these affect a force’s ability to accomplish missions. High reliability ensures weapons do not fail during combat unless hit by enemy fire. High maintainability ensures quick return of weapons back to the soldier in mission-capable condition even when hit by enemy fire. In most cases, this restorative action by the maintainer will be in situ; in the gun areas (experienced during Kargil), weapon emplacements, combat teams, refueling points and EVCs. Hence the need for combat force self-sufficiency.

The issue of equipment reliability and availability and its impact on mission outcomes, is neither discussed nor debated in any of our schools of learning or during any war games. An attempt has been made to understand this interesting subject during the Senior Officers’ course at the Military College of Electronics and Mechanical Engineering. It may be a revelation to many to know that in order to deliver a mission of about 50 km, the Mean Kilometres Between Critical Failures (MKBCF) needs to be over 150 km and for an MMG to fire three to four second lines failure free, the Mean Rounds Between Critical Failures (MRBCF) needs to be over ten second lines. What happens if the MMG suffers a mission abort failure on a post? For systems to continue to operate without any failure, the system should be ultra reliable; but then the system becomes unaffordable. Most military systems are engineered for high reliability based on the mission profile. For example, a weapon locating radar or an assault rifle may have the following metrics for battle endurance in its mission profile as a part of the PSQR:-

- Radar: Combat pulse of ten days with a 24-hour operating cycle per day, out of which 19 hours is in operational mode and five hours in travel and maintenance mode. MTBF of 90 hours initial and 180 hours final.

- Rifle: An MRBF of 5,000 round for minor faults and 20,000 for critical failures.

One does not find any such elaboration either in the user requirements or in any discussion on acquisition. In “Soviet Field Artillery in World War II” by Michael Foedrowitz, it is stated that one of the most successful Soviet guns (serial No 2464) was a 1938 model 122mm field gun which fired a total of 6,541 shells covering a distance of 4,605 km from Moscow to the Baltic coast. During subsequent examination at the factory, it was determined that the barrel had not lost its ballistic qualities and was ready for further use. As to how many maintenance interventions had been carried out to deliver this capability, there is no record. This is where the entire misunderstanding arises even at very senior levels where the common world view is that any piece of equipment lying at Ambala, Jaisalmer or Tawang will perform at full throttle when the need arises. It is no rocket science to comprehend that to be able to do so, the equipment has to undergo periodic refit and resuscitation either at the formation level or at an Army Base Workshop (ABW) where worn out, unreliable units, circuit boards and components are replaced and a fresh lease of life given to the weapon system. Such ignorance at higher level can end up creating gaps and vulnerabilities in operational preparedness, more so when the leadership has very little cross-cutting insights into weapons and equipment of other arms. Simply put, if combat systems of any arm/ service fail to perform, the ultimate impact will be on the mission of infantrymen. Going back to history, if the three AMX tanks positioned brilliantly by the operational commanders at Chusul in 1962, for providing fire support to 13 Kumaon, had not failed days before the Chinese attack on 18 November, the gallant soldiers would have convincingly defeated the adversary and saved the valuable lives of their comrades(114 killed). What a boost it would have been to the sagging morale of the nation!

In order to maintain combat effectiveness and maximise operational availability of combat systems, a few drivers of equipment capability are critical to sustainability. These are:–

- Reliability: It determines the battle endurance of a weapon system and hence the ability of a force to accomplish missions.

- Maintainability: It impacts the time needed to complete repairs and return the system back into action and resources for the same.

- Through Life Capability Readiness (TLCR): It is time this best practice is adopted to address the degradation in equipment capability due to AUD effects and plug operational capability gaps through technology refresh route. One cannot have the extravagance of replacing complex systems such as tanks, ICVs, guns and missiles every other decade taking into account the spiraling costs of acquisition and engineering.

- Spares Support: This is one critical issue which has not been addressed in the Army, unlike in other forces world over including our own Indian Air Force and Indian Navy. Spare parts provisioning is an engineering and readiness-related function and cannot be provisioned in the same manner as boots and socks. It is time to graduate to Readiness Based Sparing, besides transferring the provisioning to the maintainers. Today, perpetual shortages of critically required spare parts are constraining maintainers to support units through Hangar Queens, a sure recipe for graduating to force hollowness.

The first two drivers are holistically considered during equipment design and the last two are driven both by equipment design as well as organisational policies. For example, the M1 Abrams is reported to be aiming at MKBCF of near 1,000 km and certain modern guns have an MRBCF of over 1,000 rounds. The MBT Arjun has a unique maintainability feature of power pack getting replaced in 60 minutes. Equipment downtime can be drastically reduced if a strong focus is placed on preserving system reliability through proper warehousing, reliability restoration through planned maintenance interventions and readiness-based sparing. It is time a formalised equipment capability assessment protocol is made mandatory during administrative inspections of units and formations. It can be used as an effective mechanism to audit and quantify operational readiness of units and more importantly identify capability gaps.

Linkage Between Operations and Engineering

It is important to understand the connection between combat operations and equipment capability. Sustaining equipment capability through life, both during peace and war is critical to military capability. Just as any air force or an airline cannot carry out sustained air operations without engineering, conducting sustained ground combat is not feasible without engineering support. Operations and engineering have always been two sides of the same coin. Without engineering operations, neither can combat operations commence nor can these be sustained over a period.

Whenever engineering has failed, major disasters have occurred. It is, therefore, crucial for the Army to invest in modern maintenance infrastructure rather than questioning reset norms or indulging in destructive creativity initiatives such as GOCO. On one side, the Army is attempting a bold transformation through the creation of IBGs and on the other hand it is attempting to outsource a crucial operational capability lever by privatisation of combat maintenance support. The GOCO initiative of Army Base Workshops is akin to privatising the R&R and Command Hospitals. Imported systems such as the T 72s, T90s, T55s, AM50s, Bofors, Twins, Schilka, Kvadrat, HRVs, Scania, Tatra, L70s, and BM Grad 21 have been kept in a state of readiness only through the wisdom and pragmatism of the greying workforce of the ABWs. Simply because these men operate in the back office, their operational significance cannot be overlooked.

The modernisation of the ABWS, envisaged a decade ago, has been put on the backburner. Many soldier systems, thermal sights, weapon sights, anti-IED systems, laser designators, used by soldiers in CI operations, as also Bofors and IFGs, are reset at ABWs. The wise leadership of the Indian Air Force and the Indian Navy has not embarked on any programme to privatise dedicated base repair depots and naval dockyards. The long term implication must be well understood by the next generation leaders of the Indian Army before embarking upon such self-defeating initiatives. The GOCO did not succeed even in the richest economy; its coming to fruition under indigenous conditions of profiteering, trust deficit, corruption and military careerism is a near impossibility. Meanwhile, what has already gone into a tailspin is engineering stability in the overhaul programmes – so essential to combat force regeneration.

Concluding Remarks

In conclusion, I will end on a cautionary note that with the planned acquisition of new combat systems and ongoing organisational reset, it is important that the concept of Integrated Readiness, commonly referred to as combat force self-sufficiency is put at the centre-stage. No amount of organisational rejig will be adequate to guarantee operational effectiveness unless it takes a systems view of operational readiness i.e. soldier as well as equipment readiness. A weapon system not only requires multiple components to function in unison, but also demands from its crew and maintainers, the best practices that enable successful and consistent employment.

Dysfunctional or unreliable weapons and equipment will end up creating critical gaps in war fighting during surges of continuous operations or operational pulses, often to the detriment of the Infantry soldier. It is important that suitable metrics are evolved to define equipment capability and weapon systems are periodically assessed for readiness levels. Corrective actions can then be initiated to prevent onset of hollowness or capability deficit. It is a Chinese viewpoint, that a combat environment characterised by heavy attrition, advanced weapons and fast-paced conflicts demands unprecedented levels of technical skill. Maintenance proficiency serves as an indicator of how quickly and how frequently new techniques can be developed to enhance equipment capability and whether the expertise exists to apply them widely across the force as it fights. After all, an analysis of the 1973 Arab-Israeli War concluded, “The IDF’s ability to repair and return damaged equipment to the battlefield essentially changed the outcome of the campaign.”

Great article. These data should have been available for private sector since long time.