The development of aero-engines over the years has followed a path of rising propulsive and thermal efficiency. The design innovation of the ‘by-pass’ concept to enhance performance and efficiency in an engine, was a huge leap. The associated reduction in noise pollution and better combustion efficiency addressed the growing demand for climate control and environment protection. The concordance between the requirement of civil aeroplanes and military transport operations has contributed to dual-use technology which has benefitted both parties immensely. Combat aircraft requirements for high performance through varied ranges of altitudes, speeds and manoeuvres have been successfully met with. The super cruise and super manoeuvrability elements of fifth generation fighters have been effectively catered for but the quest for even better performance and weight reduction, is far from over.

Aeroplane aero-engine development began with the ‘In-line’ aero-engine for the Wright Flyer. While the basis for the engine was primarily to prove the success of powered flight, development of aero-engine technology proceeded at a rapid pace with significant advances in propulsion technologies and efficiency in a relatively short span of time. What followed the ‘In-line’ engine was the Radial Engine, the water cooled V-8 Engine, a design for a Ramjet Engine as far back as 1908 and the Rotary Engine. Greater requirements of performance elicited the creation of the first successful turbo-charger in 1918. A few years later, the first series-produced supercharged engine for aircraft use was developed, a two-row Radial engine with a gear-driven centrifugal supercharger.

Turbojets were developed in the post-war years to power both military and civil aircraft…

The era of the Jet Engine dawned in 1930 with Frank Whittle’s first patent for the ‘Turbojet Engine’. While Whittle’s patent lapsed due to the usual British bureaucracy, in 1935, Hans von Ohain, a research student in Germany, came up with his own patent. The first bench-test of a liquid-fuelled jet engine as carried out in 1937 in England but the first flight-test of a jet engine took was conducted in August 1939 in Germany, just weeks before the outbreak of WW II. This was Hans von Ohain’s petrol engine which powered a Heinkel He 178 fighter. Frank Whittle was to see his engine take to the air only 20 months later, powering a Gloster E 28/29 experimental aircraft. These developments virtually relegated the piston engine to history in all but the smaller airplanes.

Evolution

Turbojets were developed in the post-war years to power both military and civil aircraft. The world’s first jet powered airliner was the De Havilland Comet, which entered service in 1951 with British Overseas Airways Corporation (BOAC), the forerunner of British Airways.

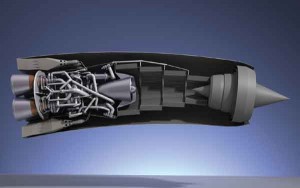

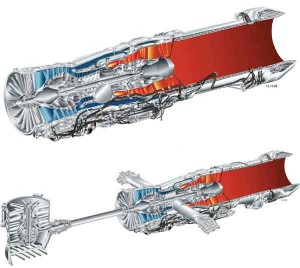

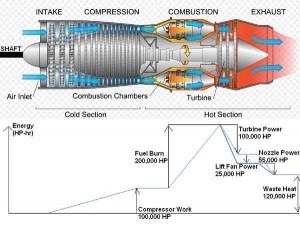

The introduction of ‘By-Pass’ engines in 1962 further revolutionised the development of jet engines. It will be interesting to note that Frank Whittle actually anticipated by-pass engines way back in 1940 when he took out patents on ‘Thrust Augmenters’. The core of a by-pass engine is the turbojet, which is surrounded by an annular by-pass duct. The increased mass flow rate caused by the fan, or low pressure compressor upstream of the core engine blowing air through the by-pass duct increases the thrust of the engine. Consequently, the propulsive efficiency, which is defined as the ratio of the power output to the rate of change of the kinetic energy of the air, is enhanced.

The other big advantage is that the relative low speed by-pass air, which surrounds the high speed jet from the core engine, reduces the high-pitched exhaust noise associated with turbojets. Modern turbofan engines are now capable of producing around 440 KN (100,000 lbs) of thrust, compared to 7 KN (1600 lbs) for the first turbojet engines. Additionally, Specific Fuel Consumptions (SFC) have halved and Thrust-to-Weight (T/W) ratios have increased significantly. Thus, the performance and reliability of these engines have revolutionised both civil and military aircraft throughout the world.

Technical Advances in Aero Engines

Aerospace engineering is a high cost, high technology sector. Design changes are visually incremental and most technical improvements occur only after considerable expenditure of time and money on Research and Development. The advent of the computer and increased capabilities of computational techniques resulted in significant trends in research, development and design of aero engines. Growth in computing power and improvements in modeling, particularly in fluid dynamics, has quickened the pace. The focus of research has been on subjects such as turbo-machinery, heat transfer, combustion and fuels, structures and dynamics, manufacturing and materials, cooling technology and fan technology.

The constant demand for higher Thrust-to-Weight (T/W) ratio engines leads to attempts to push engine technology to achieve superior performance…

Aero-engines are subjected to high turbine entry temperatures. Over the years, the maximum Turbine Entry Temperatures (TET) have increased from 1050 K for the Whittle engine in 1941 to more than 1800 K. What higher TET offers is better SFC and thrust; but subjects the turbine blades and nozzle guide vanes to prohibitive operating conditions. Thus ‘Blade Cooling’ came into effect and improvements in this field are an ongoing process. The internal air system is used to provide cooling air for the nozzle guide vanes and turbine blades which are subjected to the highest gas temperatures. Typically, in a modern engine, about 20 per cent of the compressed air is bled off for cooling and sealing purposes. Additionally, composite materials are increasingly being used to replace casings of engine components, previously cast from steel or titanium. ‘Sandwich’ constructions which create structures with high strength-to-weight ratios and increased stiffness are being increasingly finding a place in aero engine design.

Civil vs Military Operations

The basis for efficient operations, whether in civil or military aviation, is more or less akin. Thus, engine technology to power aeroplanes in both the roles has a rather significant degree of commonality. Because transport requirements for military operations have many parallels with civil operations, the similarities have led to an increasing trend towards the development of military transport and tanker aircraft based closely on civil aircraft designs. The links are even closer with regard to engine development for such aircraft and they are likely to remain so in the foreseeable future. The bottom line is that large payloads have to be carried over long distances at the lowest possible costs. Because technical advances to meet military challenges have been adopted (in many ways) in advanced civil engine applications, the reverse is also true. Thus, the two-way exchange justifies the fact that basic research revolving around aero-engines for the future be supported by both agencies, in a ‘dual-use’ mode.

Diagram of a typical gas turbine jet engine. Air is compressed by the fan blades as it enters the engine, and it is mixed and burned with fuel in the combustion section. The hot exhaust gases provide forward thrust and turn the turbines which drive the compressor fan blades.

So what is one looking at in terms of operations of the two? Fuel efficiency of combat aircraft is in consonance with the logistics and operational needs of the military because aircraft with lower fuel consumption rates would be able to remain engaged for longer periods of time, carry additional payload, reach targets from greater distances or a combination of the three dictated by operational requirements. This would translate to lesser requirement of in-flight refueling. In operational conditions, civil transport aircraft procedures of engine start, maneuvering while on the ground and take-off may not be applicable to military aeroplanes.

Operations by Combat Aircraft

Operations by combat aircraft constitute a major part of aircraft operations worldwide. Thus, there is likely to be a major difference in emission values between civil and military engines, presently and well into the future. Combat aircraft are designed for high responsiveness and entirely different mission priorities compared to those of civil operators. Combat aircraft engines are designed to extract maximum performance at the cost of accepting a shorter life-cycle, especially of high-stress components such as turbine blades and nozzles, entailing shorter periods between maintenance schedules, in comparison to their civilian counterparts. The constant demand for higher Thrust-to-Weight (T/W) ratio engines, which involve higher pressure ratios, higher peak temperatures and higher fuel/air ratios, all lead to attempts to push engine technology to achieve superior performance. Thus, in all probability, military engine technology will remain ahead of the civilian competition. Where the military needs to imbibe civil characteristics in engine design is in the area of emissions, which not only affects environmental conditions but also contributes towards ‘stealth’ characteristics, so desirable in military machines.

A major difference between combat aircraft engines and their civil counterparts is the requirement for the former to undertake extensive and extreme manoeuvres often. The combustor in the engine of a combat aircraft must be able to accommodate the consequences of high-incidence turns during combat manoeuvres, which cause unstable (sometimes severe) internal flow conditions, over a wide range of speeds and altitudes. Rapid and successful re-light, in case of a flame-out which is highly probable, is an inherent feature of combat aircraft engine design.

The Green Revolution

The subject of ‘Climate Change’ has taken on huge proportions in recent years. Numerous studies, conferences, protocols and awareness campaigns have been conducted worldwide in a bid to save the environment from degradation. Because it involves combustion, aero-engines release carbon dioxide (CO2) and other greenhouse gases into the earth’s atmosphere, thereby contributing to and speeding up global warming. Apart from CO2, other emissions are Nitric Oxide and Nitrogen Dioxide (together termed as oxides of Nitrogen or NOx), water vapour and particulates such as soot. A combination of all these have significant effect on the overall global warming.

Aircraft designers continue to look for new sources of power while they refine existing power plants…

While aviation per se, may not be the major contributor, the fact that there has been such a proliferation of aviation assets these past few decades, has increased the awareness and led to efforts to control global warming. The Intergovernmental Panel on Climate Change (IPCC), a body constituted to evaluate and quantify the sources or contributors to global warming, is involved in a series of studies to offer suitable control measures. From increasing efficiencies of aircraft and their operation, to alternative fuels and to actually proposing reducing air travel (ending Frequent Flyer Programs), there is immense pressure being exerted to control global warming which is contributing to climate change.

Trends in Aero-Engine Development

Materials: Aircraft designers continue to look for new sources of power while they refine existing power plants, both jet and internal combustion engines. There is constant effort to develop strong, light, heat-resistant materials to replace some of the metallic components in aircraft engines. Fan blade technology has enhanced performance and efficiency of the turbofan engine. The latest in this innovation is the patented ‘Diffusion-Bonded-Super Plastically-Formed’ (DB-SPF) fan blade introduced by RollsRoyce. Considerably lighter than Pratt & Whitney’s hollow titanium blade and GE’s composite blade, the DB-SPF has high strength and good resistance to fatigue as also to Foreign Object Damage (FOD). Computational modeling techniques have been at the core to developing these modern engine components.

Blisks: ‘Blisks’ have made their impact on military engine technology. Whereas in a conventional compressor the blade is fitted into machined slots on the periphery of compressor discs, in the ‘Blisk’ the blades and disc are integral, resulting in weight savings of almost 30 per cent and contributing to better T/W ratios. Blisk technology, used in the EJ200 engines, is expected to be also used in the proposed Joint Strike Fighter, a trans Atlantic collaboration.

Ultra-High-Bypass-Ratio: Ultra-High-Bypass-Ratio turbofan engines with bypass ratios of 9:1 (likely to go up to 15:1) are in the pipeline. The high bypass design necessitates increased engine size and consequently increased weight and nacelle drag. High pressure ratios require better cooling techniques, increasing complexity and probably weight of heat exchangers.

Ceramics and plastics seem to be a probability in the future…

Ceramics/Plastics: Ceramics and plastics seem to be a probability in the future. While ceramics were thought to provide the solution, their associated problems in the automotive industry have obviated their use in aero-engines. Technologies such as lightweight Polymer Matrix Composites (PMC), Metal Matrix Composites (MMC) such as titanium reinforced with silicon carbide fibres and Ceramic Matrix Composites (CMC) are in the offing. Fibre-reinforced composite materials, more like plastic than steel, are being looked at. Whilst they have the capability to withstand very high temperatures over a short period of time, will they be able to sustain in the ‘most hostile environment of them all’ – the Jet Engine?

ADVENT/AETD: The turbofan engine was a quantum jump over the turbojet and now the US is in the process of developing engine technology which will power the new generation fighters. The three engine ‘biggies’, GE, Rolls Royce and Pratt & Whitney are in collaboration/competition to develop programs to demonstrate such engines. The Adaptive Versatile Engine Technology (ADVENT) program (GE/Rolls Royce) and the subsequent Adaptive Engine Technology Development (AETD) program (GE/Pratt & Whitney) are looking at producing fuel-efficient, high thrust power plants for not only the Lockheed Martin F-35 Upgrade program, but also for the future ‘Sixth Generation’ combat aircraft. The ‘adaptive’ technology strives to improve fuel efficiency by 25 per cent over that existing presently on the F135 engine which powers the F-35, thereby increasing combat radius of the aircraft by 25 to 30 per cent and persistence by 30 to 40 per cent. It is also likely to increase supersonic cruise radius by 50 per cent and reduce aerial tanker burden by as much as 75 per cent! Anti-access and Area Denial mission capability over long distances will become the forte of the USAF.

SABRE: The crystal ball shows the growth of systems like the SABRE hybrid jet/rocket engine, capable of propelling a spacecraft into orbit or an aeroplane in the atmosphere at a velocity of Mach 5 (3800mph/3300kts/6115kph).

Reaction Engines Ltd. is developing the SABRE engine for its SKYLON spacecraft and its airliner derivative, the LAPCAT A2 Hypersonic aircraft. The SKYLON (which will precede the LAPCAT) is intended to take off and land at conventional airports.

The crystal ball shows the growth of systems like the SABRE hybrid jet/rocket engine…

It is expected to take off and accelerate to hypersonic speeds under its own power i.e. without the use of boosters. Since it will be required to operate from dead stop to hypersonic speeds, the engine is undergoing some complex technology developments.

Conclusion

The development of aero-engines over the years has followed a path of rising propulsive and thermal efficiency. The design innovation of the ‘by-pass’ concept to enhance performance and efficiency in an engine, was a huge leap. The associated reduction in noise pollution and better combustion efficiency addressed the growing demand for climate control and environment protection. The concordance between the requirement of civil aeroplanes and military transport operations has contributed to dual-use technology which has benefitted both parties immensely.

Combat aircraft requirements for high performance through varied ranges of altitudes, speeds and manoeuvres have been successfully met with. The super cruise and super manoeuvrability elements of fifth generation fighters have been effectively catered for but the quest for even better performance and weight reduction, is far from over. Materials and their usage in aero-engines will remain a daunting task. Man and machine are destined to be shackled together in their thirst for the ultimate dream.