Rising costs of Hydro-carbons, technology innovations and general inflation are an intrinsic and unavoidable part of the life cycle costs of a warship. It is evident that maritime nations will ultimately face a squeeze on their capital budgets for new military hardware. This may well be a timely opportunity for planners to examine the options available to them to control their capital expenditure (CAPEX) budgets without prejudice to their operational needs. Such a review would conclude that ships need to be designed more efficiently and their operational life increased beyond current norms. These aims can be realized if such demands are mandated by the Naval Staff. These can then be translated at the design stage and detail protocols established to ensure fleets will perform at optimum levels during their life cycle.

Science has shown that the deterioration of marine assets is preventable and can be controlled. Ships like humans, if properly cared for, can achieve longer life spans without serious prejudice to their initial performance. In fairness, it should be noted that without updates and modernization, it is not feasible for any Warship to maintain its relative international rating during its entire life span. A brand new ship will in time slide down the ladder in the hierarchy of fighting platforms. However, this shortcoming can be corrected through a half-life modernization program which is much cheaper than “a one for one” replacement. This submission does not discuss the many options regarding modernization and updates to maintain position in the international hierarchy pertinent to the class. It will suffice to say half – life modernizations are feasible, practical and necessary.

“¦without updates and modernization, it is not feasible for any Warship to maintain its relative international rating during its entire life span.

Currently, these are now being planned and implemented very intelligently by some major Naval powers.

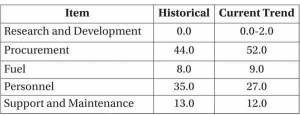

Lifecycle Costs: The total life cycle cost of any warship can be broken down into its sub-heads. These are the R&D, Procurement, Fuel, Personnel (direct and indirect), Support & Maintenance. The percentage breakdown of the life cycle costs for each of these subheads depends on the type of ship. There are certain distinguishing patterns that are worthy of closer investigation by Planners. The breakdown of the Life cycle percentage costs for a typical Destroyer equivalent are as follows:

The table shows that the percentage costs for Procurement and Fuel are increasing. This trend is here to stay. Fortunately, the cost of Personnel, Procurement, Support and Maintenance are within the control of the Naval Staff. Many large design Bureaus are now making strenuous efforts to reduce these linked costs to offset the increases already highlighted. Some of the factors influencing these costs are detailed in Table.

Crew: Personnel costs both direct (wages and pensions), indirect (recruitment, training and medical), fuel and initial procurement costs all increase with the size of the crew. It is therefore imperative that the crew be reduced to its bare minimum. Some Navies still have larger crews than others for near identical payloads. The need for cross training, cross utilization, sealed machinery and automation to attain crew reductions cannot be stressed enough. In today’s egalitarian World, there is little need for cleaners, cooks help and laundry-men etc onboard war-ships. Many of these trades are legacy requirements from a colonial era; a chapter that is now history. None of such personnel are found in the space station. Astronauts, both women and men many with Doctorates, are responsible like other millions for their own House keeping and general maintenance duties; a policy that an efficient Navy needs to emulate.

Experience has shown that every twenty years, marine equipment, weapons, and weapon systems are made near-redundant due to newer and lighter and superior replacements.

It should be noted that civilian air and marine transport now operate at much higher operational efficiencies with smaller crews motivated by very harsh and demanding economic realities. Similarly, businesses using cross training techniques continue to effect drastic cuts in their personnel ranks. Navies need to examine why they cannot maintain parity in productivity with their maritime and civilian counterparts. At the design stage, a life cycle total cost saving of Rupees 10m-20m can be achieved for a reduction of a single crew member as it affects many linked parameters in the costing model.

In addition to salaries, shore accommodations and pensions, Crews generate a hotel load that includes Fresh water, storage and make up machinery, lighting, ventilation, power generation, recreation facilities, canteens, wardrooms, galleys, refrigerated stores, sick bays, store rooms and pantries etc. A smaller ship requires less maintenance and upkeep since surface area is a function of the square of the length. There will also be a reduction of the “wet spaces” which means less surface exposure to the surrounding electrolytic fluid which promotes corrosion. The size of the crew must be carefully assessed at the design stage. Once the ship is in service, there are other details that need to be addressed if Navies are to attain the maximum life span of their Fleets.

Shock: Other things being equal, the principal driver of procurement cost of all systems in a warship is the shock requirement. Since these systems are contained on the platform, it is easier for specification writers to specify the same overall shock requirements for all systems throughout the platform. This inevitably leads to a closed system of design and procurement relying on specialized suppliers who enjoy a monopoly in the supply of very expensive shock hardened equipment. The majority of fast moving proven commercial equipment readily available off the shelf cannot qualify in such a process.

The shock intensity of modern weapons has been growing by leaps and bounds. The shock spectrum used by most designers does not often match the weapons the ship will face during its commission. If it takes a decade or more between concept formulation and delivery of the ship, it is certain that the next generation of weapons will have higher shock factors than are current. It is therefore not necessary to excessively proof harden certain equipment when statistics show that the survival of the entire Platform in collision or battle could be low.Navies are now realizing that costs can be drastically reduced if they very prudently incorporate technology that already exists and is used by Industry. The use of such open systems and shock limiting elastomeric mounts and shock absorbers drastically reduces cost and speeds up construction. The global trend is towards the use of Open Systems using shock isolation by mounted rafts and non-rigid wire suspension mounts particularized for each equipment rack or the compartment itself. Technical divisions responsible for detailing and interpreting the Statement of Requirements (SOR) often make unrealistic and unwarranted demands that result in extravagant costs. A serious effort to enforce Open Architecture where practical, will result in huge savings.

| Editor’s Pick |

Service Life: Naval fleets are national assets and the Navy is the nominated custodian. Like any other business, the Navy needs to know the as designed life expectancies of its capital assets. This information is first established at the design stage. The life expectancies of warships are a subject that is gaining worldwide momentum and needs to be addressed. In the case of new construction, the expectancy should be stipulated by the Naval Staff. New carriers should have a life expectancy of fifty years. A target of up to forty years is now feasible for other sea going ships subject to the consideration that the Ship will and must undergo a half-life refit at twenty years. Experience has shown that every twenty years, marine equipment, weapons, and weapon systems are made near-redundant due to newer and lighter and superior replacements. It has also been shown that if Hull integrity can be guaranteed, it is extremely cost effective to do a half-life modernization. An unbolt or a strip and rebuild is a preferred route when budgets are tight.

I have found this articles highly invaluable and will like to discuss my project with the author. I am currently a student at National Defence College in Nigeria and my topic is Navy Dockyard and Technology Asset Development: An Appraisal. Your input on this will be highly appreciated. Capt Pwol