Shivalik is the first ship of the Project 17 Frigates designed by the Indian Navy and built by Mazagon Docks Limited Mumbai. This project was conceived to incorporate stealth features and in the process other state of the art systems are also introduced in a modern indigenous warship. The Navy has succeeded in design and building of such a sophisticated class of warship with indigenous efforts duly supported by industry and select international agencies. The success of this project and the novel features built into the design of Project 17 Frigates are briefly highlighted in this articles.

The stealth features make it difficult for the enemy to locate this ship and the detection ranges have been considerably reduced. The modern payload judiciously selected for this class of warship adds to the lethal punch of the growing blue water capability of the Navy. The combined diesel or gas – CODOG main propulsion system provides simplicity and reliability in operations, gives higher endurance ranges and is most economical in fuel consumption. This will result in as low as one-third operating costs compared to combined gas or gas – COGOG system. The savings may be over Rs 2000 crores over the lifecycle of the warship.The lines of the ship and the form parameters have been so evolved by the designers to give the best hydrodynamic and sea keeping, manoeuvrability and handling characteristics. Even on high speeds, there is no roll, no pitch, no vibrations and the ship has turned out to be ideal, stable naval platform for naval warfare. The propellers have been specially designed for cavitation inception speeds of over 22 knots and qualify to be quiet and silent propellers.

The stealth features make it difficult for the enemy to locate this ship and the detection ranges have been considerably reduced. The modern payload judiciously selected for this class of warship adds to the lethal punch of the growing blue water capability of the Navy. The combined diesel or gas – CODOG main propulsion system provides simplicity and reliability in operations, gives higher endurance ranges and is most economical in fuel consumption. This will result in as low as one-third operating costs compared to combined gas or gas – COGOG system. The savings may be over Rs 2000 crores over the lifecycle of the warship.The lines of the ship and the form parameters have been so evolved by the designers to give the best hydrodynamic and sea keeping, manoeuvrability and handling characteristics. Even on high speeds, there is no roll, no pitch, no vibrations and the ship has turned out to be ideal, stable naval platform for naval warfare. The propellers have been specially designed for cavitation inception speeds of over 22 knots and qualify to be quiet and silent propellers.

For enhancing the warfare capability, the warship incorporates new generation technology through an indigenous system called the AISDN (ATM based integrated ship borne data network) that allows electronic information from ship’s sensors and systems to be transmitted digitally in real time over the common data base. ATM has been seen as the ultimate networking technology that will allow the true broadband working for the future. The warship incorporates advanced survivability features through robust structure, ample watertight sections and fire zones.

Habitability is considerably improved through modular accommodation totally air conditioned. The concept of Total Atmospheric Control (TAC) has been adopted where all the air intake is through the Air Filteration Units (AFUs) and the TACs controls temperature and humidity of air coming into the ship at all times. This warship caters for women officers serving on board.

Stealth Features

The primary aim of stealth is to reduce platform susceptibility, increase survivability and therefore prevent damage and reduce demands on defensive systems. Low signatures make the detection of the ship more difficult and give it more time to react. The important signature are Radar Cross Section (RCS), Radiated Noise, and Infra Red (IR).

Radar Cross Section

The Radar Cross Section (RCS) is entirely determined by the shape and material properties of the ‘above water part’ of the ship’s hull, superstructure and sensor fit. RCS of a target is its ability to capture incident EM energy and radiate back towards radar. RCS is reduced by hull-shaping, to avoid vertical surfaces and avoid corner reflectors. Radar transparent materials have been used for manufacture of guard rail stanchions and helicopter grid frames. RCS screens have been provided for the boats. Several computer programmes are available for prediction of radar signatures, which serve as an effective tool for comparison of various options and evolving a good stealth ship design. RCS reduction and prediction are generally performed in frequency range 2 – 40 GHZs.

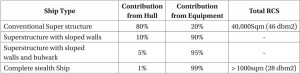

The following table shows the comparison of typical RCS values of a conventional ship with vertical surfaces and the kind of reductions possible by simple shaping and concealment of weapons, exposed deck fittings and equipment:-

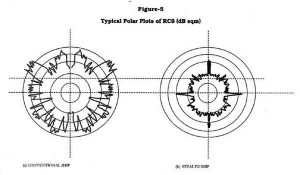

A good balance between contribution from bare hull and weapon/equipment is required to evolve an overall stealth design. A typical RCS polar plot for a stealth ship is given in figure-5.

Infra Red Signatures

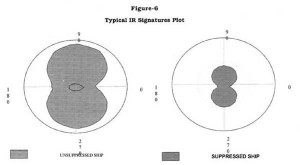

The principal sources of infra red – IR signature are the plume and hot parts of the stacks. Work on the IR signatures concentrates on the reduction of exhaust gas temperatures and cooling of visible exhaust ducting.

The electro magnetic radiation emitted by the ship from the above sources in the two infra red band widths; 3-5m (medium infra red) band and 8-12 FIR (far Infra red) band is used in designing the IR sensors to detect the ship. The IR signature of the engine exhaust can be reduced by approximately 95 percent in the 3-5m band by a plume cooling device. The IRSS device “Eductor Diffuser” system has been used for the main machinery.

A typical polar diagrams for unsuppressed and suppressed ship IR are shown in figure-6.

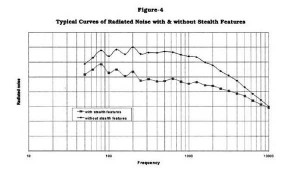

The sources of underwater radiated noise in ship are mainly from machinery both propulsion and auxiliary, flow fluid in the distributed pipe line systems and cavitation of propellers. It is necessary to employ great care to incorporate suitable noise suppression measures to achieve low noise target levels. These include resilient mounts, double mounts, rafts, flexible coupling, quiet propellers etc.

The typical curves of radiated noise with and without stealth features are shown in figure-4.

Integrated Management of Stealth

Integrated Management of Stealth

The 21st century will see more and more attention being paid to stealth features in an integrated manner to deliver the most optimum solution. Signature reduction will form only one part of a balanced stealth capability. The reduction of platform susceptibility can be achieved in a variety of ways including signature reduction, camouflage, deception, decoys, confusion, hiding and jamming. All aspects of signature management need to be coordinated at all stages of ship design, production and procurement.

Modern Payload

The payload for the Project 17 frigates has been judiciously chosen to give lethal punch and at the same time be stealth in nature. The SRGM 76 mm gun has been specially designed and manufactured for stealth features. SSM and PDMS are in VLS configuration and thus provide stealth. The area SAM and the Anti submarine RBU-6000 if made in VLS configuration for future designs will further reduce the RCS signature. The ship is equipped with variety of weapon systems for multi purpose role including anti ship, anti air and anti submarine. The weapon systems include SSM, SAM, PDMS, RBU-6000, SRGM 76 mm gun, 630 mm guns, MFR, FCRs, ESM/ECM, Sonar, CAIO, two helicopters etc.

AISDN (ATM based integrated ship borne data network)

Shivalik is fitted with third generation Composite Communication System (CCS), intelligent versatile communication system (IVCS), and sophisticated ATM based Integrated Ship Borne Data Network (AISDN) with fibre optics cable throughout the ship. The AISDN provides an integrated backbone network for voice, video, and data communications on a single broad band network. The AISDN has the following objectives :-

Some reports in the media mention, Shivalik design having been derived from a foreign acquired ship. These are incorrect reports. Instead some of the features of Project 17 had been incorporated in the acquired ships during negotiations.

- Provide a networking backbone to integrate the data of weapons and sensors to all command and control systems as well as communication systems.

- Share weapon sensor data with each other in acceptable formats.

- Provide backbone to integrate internal and external communication systems.

- Monitor the health and status of command, control and communication systems at a central location.

The AISDN system provides the required flexibility and redundancy to the users on board. ATM (Asynchronous Transfer Mode) is a standardized digital data transmission technology and is a dedicated- connection switching technology that organizes digital data into 53- byte cell units and transmits them over a physical medium using digital signal technology. ATM has been seen as the ultimate networking technology that will allow broad band networking for the future. However fast Ethernet and gigabit Ethernet have brought more bandwidth to the LAN technology and is being preferred.

CAIO (Computer Aided Action Information Organization)

Towards ensuring a multi sensor, multi weapon scenario, the Project 17 Frigates are fitted with advanced CAIO system. The CAIO system collates all sensor data for exploitation, does threat evaluation, controls and designates weapon system. In CAIO, there is central availability of all sensor data to the command for supporting decision making. This ensures no duplicity of “action taken”. CAIO also ensures sensor data fusion. It allows for “informed” decision by command due overlay of radars, EW, and other available inputs. CAIO also enables central disposition and receipt of data to and from other platforms through data link system. The CAIO for Project 17 ships have been jointly developed by Indian Navy with foreign expert agency.

CODOG (Combined Diesel or Gas) Main Propulsion and IPMS

Project 17 Frigates have been designed with CODOG main propulsion system with LM-2500 fuel efficient gas turbines supplied through HAL Bangalore and Pielstick Diesel engines supplied through KOEL India. CODOG propulsion provides simplicity in operation, achieves over 30 knot speed and minimal fuel consumption. For comparable operating profile, the consumption of fuel is nearly one-third in case of CODOG propulsion as compared to COGOG arrangement. This will save fuel costs of about Rs 50 crores per annum at prices prevailing today.

The Indian Navy has thus displayed their capability in design and building of a new generation stealth frigate with futuristic technologies.

An intelligent Integrated Platform Management System – IPMS on board Project 17 frigates, controls the operation of main propulsion machinery, auxiliary machinery, battle damage control and associated other systems.

The Propellers have been specially designed for low noise and with cavitation inception speed of over 22 knots. The inward turning propellers give narrow wake. The shaft rake is low. The shaft brackets are very carefully aligned to the flow. The stabilizers are perpendicular to the tangent to hull lines to give superior alignment. These design features have contributed to minimal noise and minimal vibrations.

Structural Integrity, Habitability, TACs – Total Atmospheric Controls

Structural integrity of very high order has been provided through robust hull structure, ample water tight sections and fire zones, special fire insulation and smoke clearing arrangements. Expansion joints are specially designed in a manner that the forward superstructure and the after superstructure are welded to the hull and the middle superstructure is suspended on bulkheads, giving freedom to the main hull to flex and allow expansion of main hull girder. This reduces stress on structure.

Habitability: Modular accommodation, totally air conditioned has been provided. Even the galley is air conditioned through separate dedicated ATUs. The automated galley will enable the crew to be fed with Indian, Continental and Asian gourmet meals including freshly baked bread, Dosas and chapattis.

The TACS – total atmospheric control – filters and controls the temperature and humidity of the air coming into the ship at all times. It removes any radioactive, chemical or biological impurities thereby protecting the crew and systems even during nuclear attack. All the air is taken through AFUs – air filtration units and there are no mushroom heads on the top deck. Three numbers citadels have been provided which are user friendly and easier to maintain. Decontamination facilities have been provided on board.

Women Naval Officers

Project 17 Frigates have been provided with accommodation for women naval officers serving on board. Their cabin has attached bathroom, bigger wardrobe space and located near the captains suite.

Conclusion

Shivalik has come out as a potent warship, as good if not better than any other advanced modern naval frigate in the world. The Indian Navy has thus displayed their capability in design and building of a new generation stealth frigate with futuristic technologies. These include integrated stealth, lethal payload with advanced CAIO, modern fuel efficient CODOG propulsion with state of the art IPMS, ATM based integrated ship borne data network – AISDN, third generation CCS and IVCS, total atmospheric control TACS.

The lines of the ship and form parameters have been so optimally evolved for most superior hydrodynamic, sea keeping, manoeuvrability and handling performance demonstrated successfully at sea during trials. Shivalik has turned out to be an ideal, versatile and stable naval platform with minimal ship motions and minimal vibrations for naval warfare. CODOG propulsion plant offers simplicity and reliability in operations with higher endurance ranges and as most economical in fuel consumption. The above state of the art and futuristic technologies have been the pride of very few select nations like USA, UK, France, Germany, Netherlands and Italy.

The lines of the ship and form parameters have been so optimally evolved for most superior hydrodynamic, sea keeping, manoeuvrability and handling performance demonstrated successfully at sea during trials. Shivalik has turned out to be an ideal, versatile and stable naval platform with minimal ship motions and minimal vibrations for naval warfare. CODOG propulsion plant offers simplicity and reliability in operations with higher endurance ranges and as most economical in fuel consumption. The above state of the art and futuristic technologies have been the pride of very few select nations like USA, UK, France, Germany, Netherlands and Italy.

India is now a proud member of this exclusive club with cutting edge warship technology. It needs to be emphasised that the Project 17 stealth frigate design is totally indigenous evolved ab-initio by the Indian Navy. Some reports in the media mention, Shivalik design having been derived from a foreign acquired ship. These are incorrect reports. Instead some of the features of Project 17 had been incorporated in the acquired ships during negotiations.

The success of Shivalik indigenous design can be attributed to various factors like continuity of the key officers directing the design, Government sanction for completing the design before the sanction for building the ships, democratic and transparent manner of working amongst design, staff and professional directorates, liberal communications and involvement with industry.

The follow-on ships of Project 17A will see refinements in design based on experience gained and lessons learnt in Project 17, design. Future ship design and construction will be influenced by advances in both manufacturing techniques and technologies, along with improvements in the ship design environment, resulting from greater use of computer base data bases and graphic tools. The next generation digital shipbuilding will simulate and optimise the entire shipbuilding life cycle process in a virtual environment from the initial development to delivery. This will increase productivity, reduce costs, improve quality in warship building.