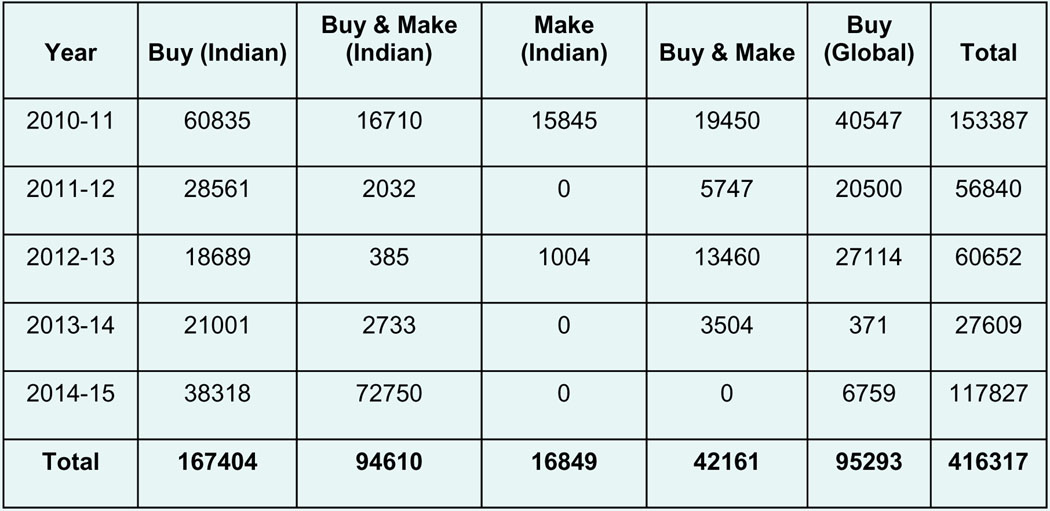

One of the positive things that has clearly emerged from the Experts Committee report is the increase in the last two years of the share of ‘Buy (Indian)’ and ‘Buy and Make (Indian)’ categories (see Table 1). The Committee attributes this to a critical change brought in DPP-2013, which provides a higher preference to these categories over others. To build on the progress, the Committee has further suggested a ‘decision flow chart’ to be incorporated in the DPP that would guide the procurement authorities to arrive at suitable procurement categories in a more credible way and consistently.

Commenting on the existing procurement structure, which was set up in pursuance of the implementation of the 2001 report of the Group of Ministers (GoM), the Committee notes that “time is ripe for a second set of reforms.” It argues that the existing structure neither has the mandate nor the expertise to further the interest of the local industry, which is expected to play a larger role under the Make in India initiative. It therefore suggests that a specialised organisation, physically separate from the defence ministry, would go a long way in bridging this vital gap. The Committee also suggests that the functionaries posted in the organization should have a longer tenure and be well trained for which a detailed curriculum should be prepared by the Headquarters Integrated Defence Staff (HQ IDS).

Emphasis on Greater Indigenisation

The Experts Committee is of view that ‘Make in India’ should not “become assemble in India with no IPR [intellectual property rights] and design control and thereby perpetuating our dependence on the foreign suppliers.” To guard against such a situation, the experts group has emphasized on progressively increasing the indigenization content, to be ensured not only through DPP-driven procurement but also by entities like DRDO, DPSUs and OFs – the three traditional players in the defence industry set up. With regard to these entities the experts group has specifically suggested that they need to imbibe an indigenisation culture and reflect it in their sourcing of parts, components and raw materials and also the final product. To ensure greater indigenisation through the DPP route, the group has suggested an incremental upward revision of the local content requirement stipulated in various procurement categories in successive DPPs. For DPP-2015, which is in the offing, the Committee has recommended that the ingenious requirement under ‘Buy (Indian)’ and ‘Buy and Make (Indian)’ should be increased to 40 per cent and 60 per cent, respectively, from the present 30 per cent and 50 per cent. And for ‘Make (Indian)’ projects, the indigenization content should be increased from the present 30 per cent to 40 per cent in DPP-2015.

While suggesting the above mentioned local content thresholds under various procurement categories, the Committee has, however, not lost sight of situations that would demand a different approach. For instance, there could be a situation involving particular air platforms in which the domestic capability is minimal and where the local industry is likely to face difficulties in achieving the stipulated local content. To cater for such a situation, the Committee has given the flexibility to the procurement authorities to lower the local content requirement. At the same time, in systems in which local capability is relatively developed, authorities would have the option of enhancing the indigenisation requirement.

Human Resource Development

Identifying human resource (HR) as a poor focus area in Indian’s defence industrialisation process so far, the Committee has made a number of vital recommendations. These include setting up a defence manufacturing sector skill council, initiating a joint MoD-industry sponsored internship programme, a provision to enable skill development through the offset route, setting up of tool rooms around defence industry clusters, and a university programme for military engineering. Although vital for creating a healthy pool of engineers and other technicians, these recommendations may not however prove sufficient to meet the critical requirements of high end manufacturing and R&D, which require a vast workforce nurtured in various defence technology disciplines. To address the HR issues affecting India’s defence R&D establishments in particular, the Rama Rao Committee, which submitted a review report in 2008 on the functioning of the DRDO, had suggested the creation of a dedicated defence technology university on the lines of the ones set up by the departments of atomic energy and space. The Prime Minister had also promised in his Aero India 2015 address to “set up special universities … to cater to our defence industry, just as we have done in atomic energy and space”. Surprisingly, the Experts Committee has neither referred to the prime minister’s address nor to the Rama Rao Committee report on this vital aspect of HR development.

Conducive Financial Framework

The Experts Committee has laid much emphasis on creating a conducive financial framework for the local industry, particularly the private sector, to do business in the defence sector. The committee has taken note of the concerns voiced by the private sector on various aspects of taxes, duties, payments terms, exchange rate variation, and cost of capital, which render its products uncompetitive vis-à-vis the products of public sector companies as well as foreign vendors. The Committee has also taken note of the discrimination towards the defence manufacturing sector vis-à-vis other sectors such as power, telecom, refinery, etc., which enjoy a host of tax benefits and other incentives. One of the glaring discriminations meted out to the local entities is in the domain of offsets, according to the Expert Committee. It has observed that the current taxation policy prevents the development of in-house system integration capacity through the offset route as foreign companies do not find it cost-competitive. In its recommendations, the Committee has suggested that deliveries by the Indian Offset Partners (IOP) may be covered under the list of ‘declared goods’ and also given the ‘deemed export’ status, which will provide the necessary incentive to foster local capability in the high-end spectrum of defence manufacturing. At the same time, the Committee has also suggested various other incentives to the local industry including the benefits of 300 per cent weighted tax deduction to the Industry’s for its contribution towards ‘Make’ projects.

Other Recommendations

In addition to the above, the Committee has also made a number of other recommendations for the benefits of the local industry. These include provisions:

- To prepare a competency map of local capability and a registry of Indian industry to facilitate decision making.

- To allow foreign companies to discharge offset obligations through subscription to defence specific venture capital funds.

- To consolidate the four defence public sector shipyards (Mazagon Dock Ltd., Garden Reach Shipbuilders and Engineers Ltd., Goa Shipyard Ltd. and Hindustan Shipyard Ltd.) into one corporate entity to take advantage of the single management of a large entity.

- To issue tenders to Indian companies having industrial license (IL) in the relevant domain.

- To allow private sector companies access to public funded R&D infrastructure and testing and proof firing ranges.

- To provide liberalized funding to MSME though the MoD’s proposed Technology Development Fund (TDF).

- To develop a robust quality assurance and standardisation system.

- To set up an independent body to ensure single window clearance for defence exports.

- To create a single window mechanism to provide regulatory and other clearances to the industry to do business under the ‘Buy (Indian)’ and ‘Buy and Make (Indian)’ projects.

In addition, the Committee has also endorsed the recommendations of past committees with regard to corporatisation of the OFs and setting up of an export arm of the DRDO on the lines of the Antrix Corporation of the Indian Space Research Organisation (ISRO).

Besides, the Committee has recommended the formulation of a 10-year roadmap for the local industry, giving specifically the measureable targets to achieve. The task of formulating the road map is assigned to the DDP. The DDP’s role in such a vital task notwithstanding, the outcome of such an exercise is in doubt as there is no high powered institutional mechanism to enforce the objectives of the roadmap. It may be noted that various stakeholders, particularly the R&D agency, manufactures and users, often work in different directions, hampering the interest of the local industry. It may also be noted that bringing all the stakeholders to a common cause has perhaps been the single biggest problem in the defence industrialisation process. A recent example is the Army’s June 2015 global request for information (RFI) to acquire what it terms the future ready combat vehicle (FRCV). The Army’s efforts have clearly upset the DRDO, which is trying to develop a future main battle tank (FMBT) through in-house design and developmental efforts. The tug of war between these two vital players is the least that the ‘Make in India’ initiative would like to bother about.

Recognising the absence of an institutional mechanism as a major handicap in India’s defence industrial growth, the GoM has suggested the creation of the Defence Minister’s Council on Production (DMCP) with its membership drawn not only from the top leadership of the defence establishment but also from other high-end science and technology ministries/departments as well as local industry. The DMCP was visualised to lay the long-term roadmap, and ensure that every possible roadblock for its implementation is removed. However, like the RUR concept of the Kelkar Committee, and the idea of a dedicated technology university of the Rama Rao Committee, the idea of DMCP has not been referred to by the Experts Committee.

Conclusion: What Next?

While making a host of recommendations, the Dhirendra Singh Committee has been cautious in assessing their impact on the domestic industry. It has therefore set 2027 as the target year by which the elusive goal of 70 per cent self-reliance can be achieved. Incidentally, the target year coincides with the term of the current Long Term Integrated Perspective Plan (LTIPP) 2012-27 of the armed forces. Evidently, if the armed forces are to be inducted with 70 per cent indigenous equipment by 2027, the recommendations of the Committee have to be implemented in right earnest and in the least possible time frame. The government has done the right thing by placing the complete report in the public domain, thereby opening its subsequent actions on each of the Committee’s recommendations to public scrutiny. All eyes would now be on the MoD as to how it proceeds with the Committee report. To say the least, a historic opportunity to establish a credible defence industry should not be allowed to wither away.

—————

1. The report is available in the official website of the Ministry of Defence at http://www.mod.nic.in/forms/Sublink1.aspx?lid=2228&Id=0

Courtesy: http://www.idsa.in/issuebrief/MakeinIndiainDefenceSector_lkbehera_160915