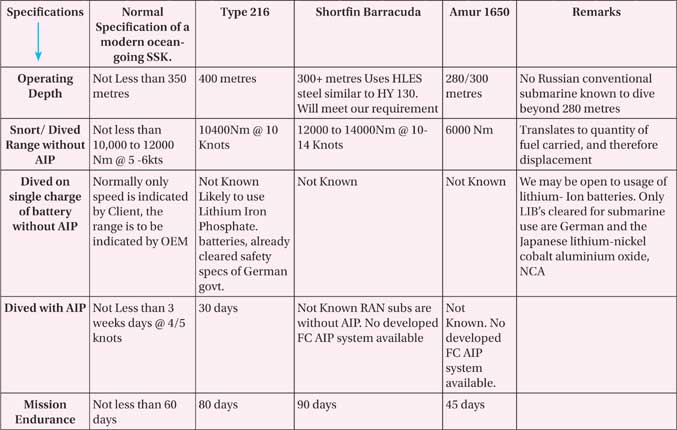

Operating Depth, Range and Endurance

The entire design and machinery/equipment fit of the platform flows from these three specifications. Known details as per open literature are tabulated below. Since the Amur 1650 does not meet any of these requirements, Russia may offer yet another ‘on paper’ version of the Amur. On paper, there exists up to six versions, starting from the 450-tonne to 1,850-tonne. The point of concern is that there is no Amur submarine built to date. The only Lada class built was rejected by the Russian Navy and the Amur was to be the export version of this rejected Lada.

Weapons

The weapons suite of P-75(I) will be nominated by the Indian Navy and is likely to consist of the tube-launched ASCM, LACM, a HWT and mining capability from both, the torpedo tubes and an external detachable mine chute. The only class to have a proven external mine saddle is the German design. As the choice/availability of weapons is beyond the scope of the OEM, the only concern is their integration capability/willingness. Towards this, the following merit consideration:

• The responsibility to obtain necessary clearances and interface data from the weapon designer will reside with Indian Navy and not the submarine OEM.

• The responsibility to obtain necessary clearances and interface data from the weapon designer will reside with Indian Navy and not the submarine OEM.

• tKMS has already indicated willingness and displayed capability to integrate any weapon as long as interface data is made available to them by the client. The Harpoon is already part of the Indian Navy inventory being integrated with the Shishumar class. They have, in the past, indicated willingness and ability to integrate the Tomahawk, Klub or the BrahMos missiles if interface details are made available.

• DCNS have been extremely reluctant to interface non-French/competitors weapon systems into their design. Case in point is the integration issues of German HWT in the Project 75. This has led to a situation that the Kalveri Class submarines will be commissioned without a HWT of our choice. To avoid such a situation again, their willingness and cost of integration should be established and factored into the final cost. Expecting the weapon suppliers to bear this integration cost, on a NCNC basis even before the weapon is selected, reflects poorly on our programme and contract management. For Project 75(I), the Russian Klub and BrahMos are not comparable in terms of range or performance of the Tomahawk. Further, the indigenous BrahMos does not have a tube-launched version yet. However, DCNS can provide us with the 900km SCALP Tube-launched LACM, albeit at a steep strategic and commercial cost. The only other source of a similar weapon would be a Government-to-Government arrangement for the Tomahawk from the US.

• Western weapon manufacturers may be reluctant to share interface data for fitment in a Russian design submarine. Fitment of either Russian or indigenous weapon package may, therefore, be a fait accompli, in case we decide to go in for a Russian design for project 75(I).

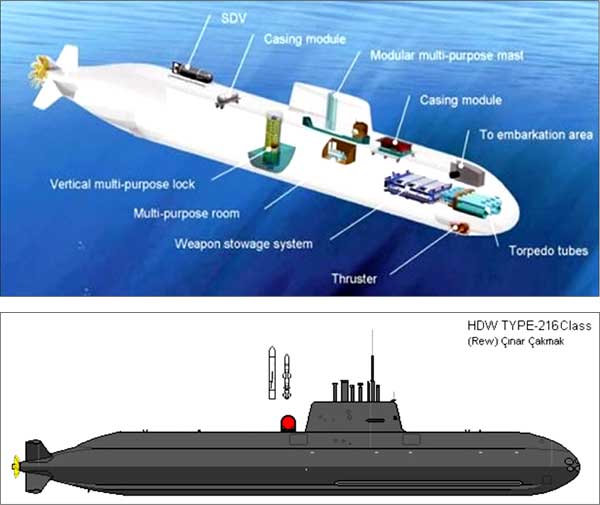

The Flexi payload concept of Type 216

The RFL mention iSTAR, mining, training and Special Forces operations as secondary roles for the submarine. The design also needs to support operations ashore in a networked environment. The Amur design does not have any known additional characteristics to cater for such requirements except the regular ESM mast and mine carrying capacity in lieu of torpedoes/missiles. The Shortfin Barracuda addresses some of these requirements by the provision of UUVs, UAVs and an ‘on hull dry dock shelter’ for divers and their delivery vehicles. The Type 216, on the other hand, complies with all these requirements by an external mine saddle and their extremely innovative and elaborates ‘Flexi Payload Concept’ with the following arrangements for mission – based modular payloads.

• Vertical multipurpose locks (3mX2.5m diameter) for Missiles, Mines, Divers Lock, AUVs and fuel oil.

• A multi Purpose Room for fitment of additional iSTAR equipment, sonar consoles, accommodation, laboratory, training and sick bay.

• Casing Payout Modules to carry countermeasures, UUV and divers propulsion vehicles.

• Modular Multi Purpose Mast for payloads such as UAV control, additional communication equipment, ESM, even to fit a gun or short range SAM.

• Weapon Stowage for additional weapons, spare bunks and general purpose stowage space.

OEM’s Current Industrial Footprint in India

Among the three OEMs, the German industrial complex already has a significant footprint in India. Industrial giants such as Siemens, MTU, MAN, ThyssenKrupp and Schneider already have a mature manufacturing and R&D ecosystem in India. This would contribute immensely towards fulfilling the mandate of comprehensive TOT, increasing indigenous content and establishing an ecosystem for local vendor base. The current footprint of the French industry in India is still nascent and in case of Russia, it is almost non- existent.

Experience in Overseas Ship Building, Attitudes towards TOT

Germany has built over 160 submarines and delivered to 20 nations. They have a proven ability to customise, based on the philosophy – ‘as small as possible and as big as necessary’. They have displayed a propensity to share submarine building technologies and capabilities with clients. South Korea has moved from the Type 209 to Type 212 and now to indigenous design Type KSS III. Turkey is building the Type 214 indigenously, with only the material package from HDW. Russia has never built any of its submarines overseas and the record of TOT is non-existent. The French are somewhere in between. While they have built submarines in a few foreign yards, their record of TOT is not as positive as that of the Germans.

Past Experience and Comfort Level of the Navy, Shipyard and MoD

The Indian Navy, yards and MoD have experience of all three OEMs. The SSK contract with HDW is considered as one of the best defence contracts, if not the best. Their operational availability, maintainability and material state even in the 30th year of commission, has been exceptional. They have been periodically modernised to retain operational superiority at MDL itself. The submarines are now being considered for their second mid-life up-gradation which would extend their life by another 12 to 15 years. The Russian Kilo class continue to be sent to Russia for refits and modernisations. Documentation received from the OEMs has been rudimentary, TOT non-existent and indigenous content minuscule. While it may be premature to pass judgement on the operational capability and maintainability of the Scorpene submarines, the project time and cost over runs have been substantial. The indigenous content and level of ToT have also been far from satisfactory. As per sources, there is no clear break-up of costs and the price escalation continues to be open ended. These issues have been raised time and again in the innumerable CAG observations, PACs, PILs and Parliamentary questions.

Conclusion

Acquisition of submarines under Project 75 (I) is the first segment to be governed by the recently promulgated Strategic Partnership framework. The focus of the RFP is likely to be TOT and indigenous content. The end state envisaged is that not only should the Navy get an extremely capable weapon platform, but the nation must acquire sufficient expertise to be able to design, build and support the next class of submarine indigenously. The Australian SEA 1000 programme was also driven by a similar aim. Their decision to acquire the Shortfin Barracuda as the replacement for their Collins Class, therefore, merits close scrutiny.

The final choice of platform under project 75(I) should, therefore, be based not only on the quality of the submarine but also on the extent of TOT and certain other factors which would be given appropriate weightage and be matrixed with the cost to determine the final strategic partner and OEM combine. Identifying these factors and assigning them inter se weightage is an involved process. While some of these factors can be culled out of the RFI/RFP, there are others factors that would be governed by our past experience, a pragmatic analysis of operational imperatives and the external environment.

So when the time comes to take the final decision for the Project 75(I), it is assumed that our collective wisdom of fifty years of submarining and previous pitfalls in the acquisition process will drive us towards a prudent, professional and nationalistic decision. But then, as a local saying goes, you can only wake up a sleeping person; one pretending to be asleep cannot be woken up. Hopefully, it will not be the case this time around!!

I was very impressed wih this article by a former senior Naval Officer until I saw that he is heading the Submarine division of Reliance Defence. Reliance defence most probably has/is partnering with ThyssenKrupp Germany for pitching Type 214/216 Submarine for the 75I program.

Even otherwise, the Germans are reliable suppliers and less susceptible to pressures. The price of course is a major factor.