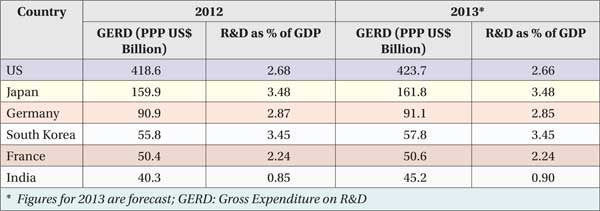

Table 6: Major R&D Spenders in the World Vis-à-vis India. Source: Battelle and R&D Magazine, 2013 Global R&D Funding Forecast, December 2012.

Manufacturing

Manufacturing accounts for 14 to 16 per cent of the GDP with 85 per cent of employment in unorganised sector, with a ‘missing middle’. This is unlike manufacturing hubs in Korea, China, Germany and Japan where 50 per cent of the firms are large with the benefit of economy of scale and 20 per cent are SEMs. Value addition in the global value chain for India was only one per cent in 2009 as against nine per cent in China and Germany. National Manufacturing Zone (NMZ) 2011 policy is limping big time in the absence of Centre – State synergy, tardy land acquisition and long drawn environmental clearances. Subir Gokran has rightly observed that increase in Incremental Capital Output Ratio (ICOR) from 3.1 per cent (2005-2006) to 5.9 per cent (2012-2013) is largely attributable to supply constraints such as power-coal imbalance and inordinate project delays.

Export Promotion

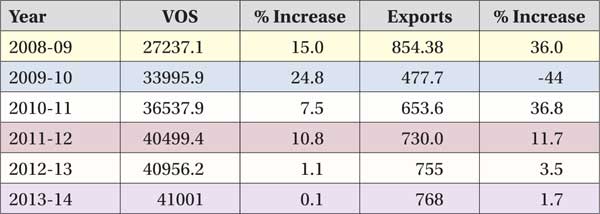

The following table provides a trend analysis of exports by Defence PSUs and Ordnance Factories since 2008 – 2009.

Of the PSUs/OFB, HAL & BEL account for 66 per cent of exports. Export as share of Value of Sales (VOS) has remained around three per cent for HAL and around three to four per cent for BEL thereby showing the policies so far have not impacted on their export performance.

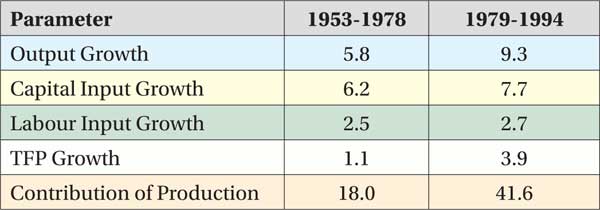

Almost 50 per cent of China’s GDP growth is attributable to total factor productivity growth…

Raghuram Rajan sounds a note of caution regarding the obsession for export-led growth by heavily subsidising inputs at the cost of fostering domestic demand. His call for “Make for India” to supplement “Make in India” is an extremely welcome alternative.

Impact of Offset Contracts

After promulgation of this policy in 2005, 24 contracts have been signed for $4.8 billion. However, discerning analysts observe that the expected benefit in terms of FDI inflow, high end technology, increased export and outsourcing have not taken place. The C&AG, in its performance audit of Fleet Tanker Contract (2010), has brought out how the full benefit of offsets provision has not been availed of from the OEM. Further, the C&AG’s comprehensive report of 2012 on offsets contracts severely castigates the inept contractual arrangement that underlies such offset arrangements and additional cost implication.

Manufacturing, “Make In India” Policy and Defence Manufacturing

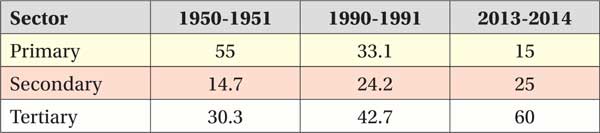

Since liberalisation in the 1990s, the sectoral share of the primary, secondary and tertiary segments shows a tectonic shift wafting through the corridors. The share of Agriculture in the GDP shows a significant reduction while the share of Industry has remained stagnant with the Service sector showing the way as the sunshine sector.

The following table brings out the trends in the compositional shift.

A disaggregation of the Secondary sector shows that the share of manufacturing sector has increased from around 15 per cent to 25 per cent. The experience of manufacturing giants like Germany, South Korea and China reveal that manufacturing accounts for 30 per cent of their GDP.

The defence industry, be it public sector or private, has to be part of the national manufacturing policy mosaic…

Therefore, the thrust of the government to encourage “Make in India” option by facilitating the enabling environment to manufacture, improving ease of doing business, encouraging creation of national manufacturing zones in tandem with the states and investing one trillion dollar through the PPP route in the infrastructural sector make eminent sense. Professor Basu rightly observes out that the success of the “Make in India” policy will critically hinge on the cost of doing business in India.

Two critical factors for this would be the quality of human resources and cost of capital. India’s education system is presently mired in a mess and needs millions of skilled workers coming out of the ITIs with quality training. While access to education at the primary level through the Right to Education has improved access significantly, the quality deficit, both in the primary segment and higher education is palpable. While the private sector has contributed handsomely to the growth of technical and management education, the quality of education and lack of research impact on the employability of students adversely despite the global opportunity.

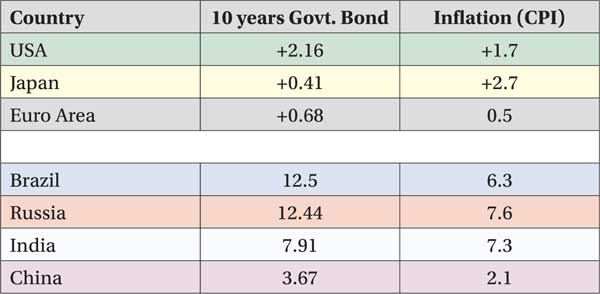

As regards the Cost of Capital, the following table would bring out the disturbing trend of exorbitant Costs of Capital in India compared to the developed countries.

What is interesting also to note that most of the BRIC countries are bedeviled by high Cost of Capital and unacceptable levels of inflation accentuating their “Misery Index”.

Importance of Total Factor Productivity

Professor Solow, a Nobel Laureate, in his seminal paper had brought out the importance of factor productivity. His equation Q=A * K∆ Lβ where Q is the production function, A is the level of technology and scale, K & L are factors of production ∆ & β are factor efficiency has demonstrated how US has become the premier technological hegemon after World War II. A case in point is the phenomenal growth in China from 1979 as would be evident from the following table. Almost 50 per cent of China’s GDP growth is attributable to total factor productivity growth.

Table 10: Sources of Growth in China. Source: A.P. Thirlwall - Economics of Development-Theory and Evidence

Lessons for India’s Defence Industry

The defence industry in India cannot be impervious to these trends. It has to be sensitive to skill requirements in order to absorb high technology which comes as part of ToT. One of the predominant reasons for Japan’s phenomenal growth since the 1950s has been their highly skilled labour force which could absorb front-end technology from the US quickly and adopt it to harness commercial success through dual use technology. Japan’s success in electronics and automobile is testimony to this.

The DRDO remains mired in inordinate delay, huge cost overruns and deficient in critical technology areas like ‘seekers’ and ‘stealth’…

In India, on the other hand, the ToT experience reveals that the technology absorption has been inordinately slow leading to continued dependence for our foreign collaborators well beyond the originally contracted period. Experience of HAL in terms of production of the MiG series of aircraft and SU-30 and for MDL for producing Scorpene submarines are grim reminders of our poor high skill absorbing capability.

Conclusion

India is witnessing a significant stickiness in its manufacturing sector which is bedeviled by the huge presence of small scale and informal sector that are bereft of requisite skill levels and economy of scale. Their access to capital is also seriously impeded. However, the manufacturing sector provides a wonderful opportunity for India to be part of the global supply chain and generate high levels of employment opportunity to absorb around ten million young Indians who will come in to the market in search of employment every year. They also need to be properly skilled and trained and networked with their global peers.

The defence industry, be it public sector or private, has to be part of the national manufacturing policy mosaic. Unfortunately, the defence sector often chooses to distance itself in its interface with other civilian sectors. There is opportunity aplenty in areas such as aerospace and ship building where there is considerable civilian and military market. Lack of design capability to manufacture critical subsystems remains a major handicap. The DRDO remains mired in inordinate delay, huge cost overruns and deficient in critical technology areas like ‘seekers’ and ‘stealth’.

Tokenism like Rs. 100 crore allocation towards Technology Acquisition Fund or lip service to FDI policy by increasing to 49 per cent are not the way forward. Public Private Partnership, Joint Venture with foreign OEMs and design houses will require bolder policies such as FDI ceiling higher than 50 per cent and the political will to mentor and hold together the different stakeholders who are often at cross purposes. The new Prime Minister has set his foot in the right place. The Ministry of Defence, however, has to match his steps, shed its ghetto mentality and strive for better synergy with other manufacturing sectors to make “Make in India” the mantra for the days ahead.

Very good insight and analysis. The only turnover doesn’t tell the complete picture. This means a turnover of Rs 20,000 Crs at OFB will be equivalent to around Rs 21,800 Crs in terms of value addition.

India offers tremendous opportunities in engineering services, supply chain sourcing and associated maintenance, repair and overhaul-related activities, however to achieve self-reliance we need to create a robust ecosystem that can address the capacity and capability requirements for the industry.

Low productivity in defense sector is a serious problem for national security. India must have a capacity of at least 200 fighter planes , 500 tanks , 500 armored personal carrier . 1000 guns and mortars and their ammunition annually. Only public -private partenership in R&D and production can resolve this problem. Relation with China and Pakistan will remain hostile .

Very good article sir. We are a NAM nation, if we harness our defence capability, then we have seamless opportunity with a big market.

Nice article Dr. Sharma. I wonder if there is any incentive to encourage MSMEs to invest in defence manufacturing. India will have to largely involve MSMEs if it wants to become self reliant in defence manufacturing, otherwise PSUs will continue to be integrators and do low value addition than actual manufacturing.

Thx,

Dr. Praveen Srivastava

Comment that value addition of OFs is 85% because of low technology items is because of ignorance. OFs manufacture bulk of land systems and ammunitions. Any stretch of imagination can not categorise these as low tech. Rather all high end manufacturers are vying for manufacturing the land systems and ammunitions by screwdriver technology. It is only Ordnance Factories, which make items in a self reliant manner. OFs may be doing it under ToT but after absorbing and indigenising it. That is how their value addition is high. It is much better than getting the sub systems and assembling them.

Nice Article , Sir

As per your vast experience , which product would be the best to propagate in India’s Defence.

I am very interested in the “Make in India” concept but not able to get a foreign defence company to show interest in our Defence programmes .

I hail from a family of 5 defence fauji officers . I would appreciate it if you could guide me accordingly.

Any suggestions.

We have our office in Delhi.

Dennis

Jai Hind !!

Skype : denniscollins128

+91-8688597499

+91-7569778889

Excellent and in-depth analysis.As pointed out, unless & until private, public and Govt. have desire to develop technology through R&D efforts, make in India compeign will either not succeed or be infractus

Author has tried to make a good attempt by interweaving many aspects that will contribute to defence manufacturing in India like requirements of fund for new technology development, status of GERD in India, status of SMEs in India, FDI in defence manufacturing, Offset policy , skill requirements and development , ease of doing the business at low cost etc. However, interweaving of various factors, its interdependence and its effect on defence production has not been done properly. Similarly, some of the facts have not been presented properly, for example level of indigenization has been shown 85% for OF, but the reason attributed is that OF is in low end technology. OF make variety of products right from uniform and shoes for Siachen to tanks, ICVs, small arms, ammunition, B-vehicles, artillery weapon etc which can not be grouped in low technology area. Similarly, SME in Japan are present in big way in manufacturing, but they are not in competition with big industries , but they are working in collaboration with them.

To boost up make in India in defence, one has to ensure that market comes before production. Defence industries works in monopolistic or oligopolistic market. Without assured market for a reasonably long period, nobody will invest their money. So, first reform has to be made at demand side. There should be a long term perspective plan for acquisition where specifications needs to be frozen for a reasonable period of time keeping in mind the availability of technologies at competitive and affordable cost, strategic requirements based on capabilities of potential adversaries and incubation period of next generation weapon system development. SQR should not be based on whims and fancy of decision makers . Manufactures views should also be taken while framing GSQR. If a contract is won by one company , then it should supply 5 to 10 years till it recovers its return on investment, technology technology is phased out globally or becomes irrelevant .

Firstly our curriculum from High School level should be changed to Skill based knowledge on practical applications.Howmany students can identify a spanner, screwdriver or electric current? Very few.Without basic knowledge students cannot pursue research.

There is a major flaw in the author’s understanding of shipyards whether private or public sector. Shipyards are locations where the ship/ submarine is brought together . Shipyards do NOT make systems , or even valves ! They come from subcontractor MSME factories in the hinterland. Modular / Integrated construction is the way ahead for shipyards to speed up construction. That requires up gradation of facilities and land. Lastly we need orders on frozen staff requirements from users navies. Midway changes slows down production to a crawl. The IN is leading the Builders Navy concept for many years now and can do much more with a focused thrust in our public and private shipyards. HOW? Our strategic tasks are many as we stand challenged in the Indian Ocean as never before by China. Our need is numbers now as older units need to be replaced / retired in the next 25 years! So time to build is now for the next 25 years at a frenetic pace, whether it is ships , submarines or Naval LCA fighter aircraft.

Certainly India has ignored R&D in this sector, but although it is a little too late, yet we can now rectify our strategy, collaborate with best manufacturers, set up specialised recruitment and training centres to exploit our best brains and in the next ten years make productive products for domestic and overseas use. Raising funds from the stock markets by manufacturers in due course of time may also be permitted. Long term benefits clearly can come our way !

We dont have a good R&D base – we need to drastically improve and expand our R&D base. All IITs and Engineering Colleges in the country should be co -opted in expanding our defence tech base. We should also improve the intake of Scientists into the DRDO. They are lowly paid Government Servants with little motivation. I have met many during my service and was not at all impressed with them. Some of them even complained of being shackled and not given the freedom to work.

The DRDO has been responsible for the armed forces not getting the latest technology. It has always lobbied with the govt that they will produce the required system – One example is the INSAS weapon system. They took years to produce an out dated weapon – its basically cut paste technology. Even its manufacture at RFI is poor – its stamped cut rather than a moulded configuration. If you cant produce something of your own – steal technology as the Chinese have done but dont delay us. You cant even produce precision ammo for the artillery. Shabby job if you ask me.

With due respect sir , are you from Indian army , if yes then you should have known that INSAS was developed and manufactured by OFB , not DRDO . Do your home work properly before scribbling nonsense