With the NDA coming to power, there has been a renewed effort to energise defence manufacturing. The NDA government has increased the FDI limit to 49 per cent and constituted a committee under Dhirendra Singh, to suggest ways and means to infuse momentum into ‘Make in India’ in defence manufacturing. The Committee has come up with a recommendation to have a Strategic Partnership (SP) Model where one or two private sector players would be identified in manufacturing sectors such as Aircraft, Warships, AFVs, Guidance Systems, CCI and critical materials. It has also suggested that a specialist organisation should be created for handling issues such as acquisition. The SP model clearly reminds one of the RUR model, advocated by Probir Sengupta. It is like old wine in a new bottle, which is likely not to see the light of the day, as the parameters for selection are opaque.

Economic liberalisation has been a game changer, when parties cutting across ideologies have realised that the raw energy and dynamism of India’s private sector must be fully tapped…

2001 was a watershed year for the defence sector, as the government decided to allow 26 percent Foreign Direct Investment (FDI) and full participation of the private sector in defence manufacturing. Prof Vijay Kelkar recommended that a level playing field should be provided to the private sector players and a Public-Private Partnership (PPP) model tried out, on the lines of success achieved in telecom, national highways and airports. He also brought in a whiff of fresh air through a new offsets policy, which will leverage ticket acquisitions to get key technology, outsourcing orders and FDI from the Original Equipment Manufacturers (OEMs). The National Manufacturing Zone Policy (2011) also suggested that defence manufacturing should be part of the overall manufacturing momentum. However, there has always been a niggling feeling that the private sector companies were the outliers while the PSUs have a privileged status.

Economic liberalisation has been a game changer, when parties cutting across ideologies have realised that the raw energy and dynamism of India’s private sector must be fully tapped. The Probir Sengupta Committee argued that RUR status should be given at par with the Navaratna DPSUs such as HAL, BEL and MDL to a few private sector players such as the Tatas, L&T, M&M. These recommendations, however, did not find favour as many players in the private sector, particularly in the field of IT, felt that the parameters for selecting RUR were tailor-made to favour a few private sector players.

It is in this backdrop that the Ministry of Defence (MoD) introduced a significant change in its shipbuilding procedure in 2008, when the private sector players were allowed to compete for manufacturing surveillance vessels. This witnessed an exciting competition between Goa Shipyard Ltd (GSL), a defence shipyard and private shipyards such as Pipavav, L&T and ABG, for manufacturing surveillance vessels such as Offshore Patrol Vehicles (OPVs) and Inshore Patrol Vehicles (IPVs). The level playing field experiment won orders for the private players. To their credit, they have delivered the IPVs much faster and at a much lower price than what was being quoted by GSL, with its entrenched monopolistic position. This has clearly vindicated that competition is the key to fairness and low cost.

The ‘Buy’ option viz importing weapons platforms and systems from OEMs, has been the first priority of the services…

The Structural Concerns

Yet, the defence manufacturing sector is bedeviled by structural concerns. Firstly, the services, the manufacturing agencies and the research organisations as the stakeholders, often act at cross purposes leading to interminable delay, high cost and blame game. A classic case is that of the Light Combat Aircraft (LCA) Tejas which was to replace the ageing Mig-21 aircraft. Right from the beginning, the Indian Air Force (IAF) was not sanguine about GTRE’s capability to deliver a gas turbine engine. Hindustan Aeronautics Limited (HAL), the manufacturing agency for the prototype and the production version, felt that converting DRDO’s design to a prototype is a serious irritant.

It may be recalled that Chidambaram Subramaniam Committee (1964) had noted that India does not have domain knowledge in aero- engine design. The Committee had strongly advocated that there should be collaboration in design with major design houses such as RollsRoyce, GE or Snecma. However, the DRDO pressurised the government to go ahead with an indigenous engine design programme, called Kaveri, which failed the design audit of M/S Snecma, after running the programme for 15 years. The programme is now shelved and the indigenously built LCA Tejas aircraft will be powered by a GE 414, an engine from the USA!

It is in this backdrop it would be interesting to go through the indigenisation and ‘Make in India’ initiatives in India.

Self Reliance Index

The ‘Buy’ option viz importing weapons platforms and systems from OEMs has been the first priority of the services, as they dread the interminable delay and capability of indigenous initiatives. The technology transfer route, ‘Buy & Make’ is the second option, where the imported parts are assembled and integrated with a fair degree of dexterity by the DPSUs. However, value addition is a serious concern in this route, as major platforms such as the Su-30 MKI aircraft have clearly demonstrated. In the ‘know-how’ route, building design capability is a huge casualty. It is because of our lack of depth and commitment to indigenous Research and Development (R&D). As a result, the ‘Make in India’ initiative has taken a serious beating with our Self-Reliance Index as low as 30 per cent. The Self-Reliance Index is particularly poor in sub-systems such as propulsion, weapons and sensors where our dependence on imports is abnormally high.

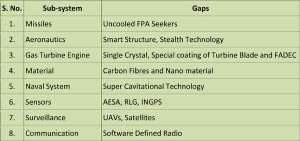

In 1993, a committee under Dr APJ Abdul Kalam had identified the following critical technology gaps.

Critical Technology Gaps

The technology gaps (given in table) linger in India, without any perceptible improvements. The Committee had recommended improvement of our Self-Reliance level to 70 per cent by 2005 by developing work centres at the national level and bringing together PSUs, DRDO, ISRO, CSIR, DAE, private sector and academia on one platform. The Committee had recommended that instead of setting up separate test facility by each research organisation, National Centres should be created for building infrastructure for design and development for the nation as a whole.

The technology gaps (given in table) linger in India, without any perceptible improvements. The Committee had recommended improvement of our Self-Reliance level to 70 per cent by 2005 by developing work centres at the national level and bringing together PSUs, DRDO, ISRO, CSIR, DAE, private sector and academia on one platform. The Committee had recommended that instead of setting up separate test facility by each research organisation, National Centres should be created for building infrastructure for design and development for the nation as a whole.

There is also a strong case for disinvestment of Navratna DPSUs such as HAL, BEL and the MDL…

Strategic Partnership Model

With the NDA coming to power, there has been a renewed effort to energise defence manufacturing. The NDA government has increased the FDI limit to 49 per cent and constituted a committee under Dhirendra Singh, to suggest ways and means to infuse momentum into ‘Make in India’ in defence manufacturing. The Committee has come up with a recommendation to have a Strategic Partnership (SP) Model, where one or two private sector players would be identified in sectors such as Aircraft, Warships, AFVs, Guidance Systems, CCI and critical materials. It has also suggested that a specialist organisation should be created for handling issues such as acquisition. The SP model clearly reminds one of the RUR model, advocated by Probir Sengupta. It is like old wine in a new bottle, which is likely not to see the light of the day, as the parameters for selection are opaque.

Lessons from DGA & DARPA

In this backdrop, India can take a leaf out of the experiences of the DGA in France and DARPA of USA to rev up our defence manufacturing and research. The Directorate General of Armaments in France is the procurement and technology agency responsible for programme management, design and development and procurement of weapons system for the French military. It coordinates the armament programme with local industries in France and other European countries besides customers for exports. It has also entered into cooperative armament programmes such as Combat Tiger Helicopter, Surface-to-Air missiles and Anti-aircraft systems. The entire gamut of design, development, acquisition, collaborative arrangements and exports are thus handled by one overreaching organisation. It would make eminent sense to consider replicating such an institutional model in India. This was strongly advocated by the Sisodia Committee (2009), who had observed with concern the lack of professional expertise in handling such issues in the Acquisition Wing of the MoD.

Furthermore, in countries such as the USA, the private sector is treated as a partner from the design and development stage to manufacturing and maintenance of weapon systems. DARPA, which was created by President Eisenhower in 1958, in response to the technological surprise thrown by Sputnik of USSR (1957), is a frontline research organisation which collaborates with academia, industry and the government for developing of emerging technology required by the military. The DRDO of India needs to draw lessons from the functioning of DARPA.

We need to encourage synergy between academia, industry and the government…

The Way Forward

We need to encourage similar synergy between academia, industry and the government. The ‘Make’ procedure in DPP envisages that 80 per cent funding can be provided to private agencies for developing prototype. However, given the poor pace of the ‘Make’ progammes, such funding is hardly availed of. The MoD also came up with a policy paper in 2010, to provide funding support to academic institutions and industry for design and development of state-of-the-art systems. This was with a view to improving our self-reliance quotient in critical technologies.

There is also a strong case for disinvestment of Navratna DPSUs such as HAL, BEL and the MDL. The government must also allow the private sector to enter into production of helicopters and transport aircraft for the IAF as also frigates and submarines for the Indian Navy as they have done for the surveillance vessels. The present limit of 49 per cent in FDI must be increased to 51 per cent as that would attract OEMs to set up manufacturing base in India and bring in critical technologies.

If India wants to become a global manufacturing hub in defence production, the NDA government must give ‘a big push’ to increase FDI in defence. The DGA model of France and collaborative R&D model of DARPA should be seriously considered for galvanising indigenous research and manufacturing capability of critical sub-systems.