Unfortunately, in all deals concluded by India under ‘Buy and Make’ procedure, Phase 3 is never reached. At best, indigenous manufacture is restricted to assembly under Phase 2. This arrangement suits both OEM and public sector units ideally. OEM does not transfer any know-how but keeps getting orders for continued supply of sub-assemblies and critical components. Concomitantly, public sector units remain assured of confirmed orders from the services and earn huge profits without any sweat. Apparently, no meaningful technology is sought and obtained. The fact that not a single imported technology during the last three decades has provided a springboard for the development of superior technologies testifies the total failure of the current dispensation. This is the prime lacuna of seeking technologies under ‘Buy and Make’ procedure.

Analysis of Range, Depth and Scope of Technology on Offer

For effective negotiation of ToT, it is essential to break down the overall technology package into sub-technologies to ascertain true range, depth and scope of technology being offered. Therefore, DPP mandates that OEM should be asked to identify each item (system/sub-system/assembly/sub-assembly/module/part) in the product structure under the following five categories:-

It has been seen that every single ToT contract signed by India runs into trouble and it is always India whose interests suffer. Indian negotiators consider drafting of contracts to be drudgery”¦

- Category 1. Items for which complete technology to enable the recipient carryout fabrication, assembly and test of the item is being provided by OEM. Such items should be classified under the head ‘Complete Transfer of Technology’ or C-ToT.

- Category 2. Items which are manufactured by OEM’s sub-contractors based on the engineering documentation provided by OEM and the said documentation is made available to the recipient. Such items should also be classified as C-ToT.

- Category 3. Items whose development and manufacture has been sub-contracted by OEM to his vendors/sub-contractors based on the procurement drawings/specifications provided by OEM. Apparently, OEM can only provide the same drawings/specifications to the Indian recipient and nothing else. For the purposes of evaluating the depth of technology being transferred, it should be presumed that the technology in respect of such items is not provided. In case OEM, in collaboration with his vendor/sub-contractor, is able to provide maintenance documentation and training, the items should be classified under the head ‘Limited ToT for Maintenance Support’ or M-ToT.

- Category 4. Items sourced by OEM against his procurement specifications as ‘Fully Finished’, may be considered as bought-out. OEM will only be able to provide the procurement specifications and the sources of supply to ensure availability during the life cycle of the product. In case OEM, in collaboration with his vendor, is able to provide documentation for maintenance and training, such items should also be classified under the head M-ToT.

- Category 5. Items for which OEM is not willing to transfer technology (despite having the ownership of design and manufacturing documentation) should be classified as ‘Proprietary’ items. These items are generally not included in the scope of ToT. Needless to say, the list of such items should be as small as possible.

Further, DPP stipulates that OEM not offering the key specified technologies under C-ToT (categories 1 and 2) and maintenance technologies under M-ToT (category 3 single source vendor assemblies) should not be considered for ‘Buy and Make’ order.

Value Addition

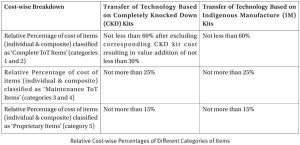

As ToT has to result in indigenous production and carries a cost penalty, it is equally essential to procure cost-wise breakdown of various categories of items from OEM. It is only then that true extent of value addition can be commuted. DPP provides guidelines as regards limits of relative percentages both for CKD kit and IM kit based ToT. These have been shown below in a tabulated form.

| Editor’s Pick |

DPP further stipulates that no item which is critical either from the technology point of view or which constitutes a significant relative percentage of the product cost (say>10%) should be accepted as a ’Proprietary’ item. In addition, no single item, which constitutes more than 10 percent of the cost of the product, should be kept outside the scope of ToT. In case such an item belongs to the ‘bought out’ category, OEM should bid in consortium with the concerned sub-contractor/vendor for ToT assurance.

Finally, depth of technology should enable the recipient to achieve value addition of a minimum of 60 percent of the relative cost of the licensed product through indigenous manufacture. Undoubtedly, the exact percentage of value addition would vary based on the product. Unfortunately, no records are made available in public domain to indicate details of value addition achieved at various stages of indigenous production under licence.

Negotiating ToT Contracts

It has been seen that every single ToT contract signed by India runs into trouble and it is always India whose interests suffer. Indian negotiators consider drafting of contracts to be drudgery and prefer to ask foreign OEM for draft contracts. Needless to say, draft contracts are always loaded in their favour. Perfunctory scrutiny is carried out by Indian officials for major issues. Small print that escapes Indian notice invariably proves detrimental at a later stage.Although DPP lays considerable stress on the details to be included in the contracts, Indian negotiators generally fail to ensure compliance. Failure to negotiate a fool-proof contract results in multiple interpretations of its provisions during the implementation stage and causes bad blood due to frequent squabbling and legal wrangles.

It has been seen that every single ToT contract signed by India runs into trouble and it is always India whose interests suffer. Indian negotiators consider drafting of contracts to be drudgery and prefer to ask foreign OEM for draft contracts. Needless to say, draft contracts are always loaded in their favour. Perfunctory scrutiny is carried out by Indian officials for major issues. Small print that escapes Indian notice invariably proves detrimental at a later stage.Although DPP lays considerable stress on the details to be included in the contracts, Indian negotiators generally fail to ensure compliance. Failure to negotiate a fool-proof contract results in multiple interpretations of its provisions during the implementation stage and causes bad blood due to frequent squabbling and legal wrangles.

The contract should be comprehensive and all-inclusive. There should be no loopholes which an insincere OEM can exploit to renege from contractual obligations. As recommended by DPP, special attention should be paid to the following aspects by the contract negotiating team to safeguard Indian interests:-

ToT must fill critical gaps in indigenous knowledge and help accelerate the process of achieving self reliance. Therefore, its selection should be need-based and not availability-based.

- Supply of Required Documentation. All documents should be sought in English to obviate time penalty and misunderstandings in translation. The documentation should be the one used by OEM or his sub-contractors for the purpose of manufacturing, assembly and testing of the product in their plant. It should be exhaustive enough to enable the recipient to manufacture, assemble, test, install and commission, maintain and overhaul the product. Wherever approval of certification agency is relevant, it should also be provided.

- Product Upgrades. An undertaking should be obtained from OEM with regard to provision of technical data and Configuration Control Documents in respect of any modifications, improvements and upgrades undertaken by it during the entire life cycle of the product, at no additional cost. All updates during the currency of the contract should be provided as and when issued free of cost. A consolidated list of all updates during the year should also be provided during the first quarter of the subsequent year.

- Training. Comprehensive industrial training should be provided to the recipient in English language, both in classrooms and on-the-job. It should cover all aspects of design, manufacture, software, system integration, installation and commissioning. Training for testing and component level maintenance is equally important.

- Technical Assistance. The recipient of technology should be assured of technical assistance by OEM and his sub-contractors during various phases of the manufacturing programme. Such assistance should be mentioned in the contract in terms of man-weeks spread over a number of missions. In addition, it should be obligatory for OEM to provide answers to all questions raised by the recipient in an honest, detailed and expeditious manner, at no extra cost.

- Provision of Special Maintenance Tools and Test Equipment. Complete technical data of all Special Maintenance Tools (SMTs) and Special Test Equipment (STEs) used in the production, assembly, test and maintenance of product should be provided. Data for manufacture and maintenance of such SMTs and STEs along with their calibration details should also be made available. Wherever software is used, details of the software including Source Code and Firmware Support Manual for embedded software must be provided.

- Product Support. OEM must assure complete product support including supply of spares and management of obsolescence for the specified period. At any stage during the life cycle of the product, if the OEM intends to discontinue the production of Proprietary items, the complete technical documentation in respect of these items available with OEM or his sub-contractors should be provided to the recipient to enable him to develop alternate sources. List of consumables required for the manufacture/maintenance of product along with cost, source details and life data should also be provided. As regards special technologies, special coatings and treating processes of specific components/assemblies, the contract must make it obligatory for OEM to provide their details. OEM should also undertake to assist the recipient obtain all possible support for M-ToT from his vendors/sub-contractors.

“¦the concept of ToT under “˜Buy and Make needs to be revisited. Production based on SKD and CKD kits should be excluded from the ambit of ToT.

- Delivery Schedule. Complete schedule for transfer of documentation, provision of industrial training, technical assistance, supply of kits, spares, SMTs, STEs, tools, jigs and fixtures must be included in the contract. Default must attract claims for liquidated damages.

- Development of Local Vendors. The recipient should be at liberty to develop local vendors and sub-contractors for the supply of components and sub-assemblies. No provision should bind the recipient to procure such items from OEM alone.

- Warranty. OEM should provide warranty both with respect to documentation and the material. Documentation supplied must be identical, complete and of equal quality as the documentation used by OEM for his own activities. Similarly, items supplied should be free from any defects arising from faulty material, design or workmanship and should be guaranteed for quality. OEM should also guarantee the performance of the product to design specifications.